Polyethylene-methacrylic acid-polyethylene polyamine fiber and method for preparing same

A polyethylene polyamine fiber and methacrylic acid technology, which is applied in fiber treatment, chemical instruments and methods, and other chemical processes, can solve the problems of low amine content, cumbersome preparation process, and difficult source of hair fiber material matrix. Achieve the effects of increased amino group content, simple synthesis process steps, and low raw material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Use 5g of PE and add 200ml of ethanol to extract in a Soxhlet extractor for 4 hours, put it in a 3-neck bottle after drying, add 100ml of DMF, and swell at 30 degrees Celsius for 4 hours. Add reactive emulsion, PE fiber, reactive emulsion and initiator ratio are as follows:

[0037]

[0038] Heated in a water bath at 85°C, and stirred at a speed of 60r / min for 12 hours. The PE-MA-N obtained from the reaction was subjected to solid-liquid separation, washed with acetone, and dried in the air. Vacuum drying at 50°C to obtain a finished polyethylene-methacrylic acid-polyvinylamine fiber. Its physical and chemical properties are as follows:

[0039]

Embodiment 2

[0041] Use 5g of PE and add 200ml of ethanol to extract in a Soxhlet extractor for 4 hours, put it in a 3-neck bottle after drying, add 100ml of DMF, and swell at 30 degrees Celsius for 4 hours. Add reaction emulsion, the addition of each component in the reaction emulsion is as follows:

[0042]

[0043] Heated in a water bath at 90°C, and stirred at a speed of 60r / min for 18 hours. The PE-MA-N obtained from the reaction was subjected to solid-liquid separation, washed with acetone, and dried in the air. Vacuum drying at 50°C to obtain the finished polyethylene-methacrylic acid-polyvinylamine fiber of the porous fibrous absorbent material, whose physical and chemical properties are as follows:

[0044]

Embodiment 3

[0046] Use 5g of PE and add 200ml of ethanol to extract in a Soxhlet extractor for 4 hours, put it in a 3-neck bottle after drying, add 100ml of DMF, and swell at 30 degrees Celsius for 4 hours. Add reaction emulsion, each component add-on in reaction emulsion is as follows:

[0047]

[0048]

[0049] Heated in a water bath at 95°C, and stirred at a speed of 60r / min for 24 hours. The PE-MA-N obtained from the reaction was subjected to solid-liquid separation, washed with acetone, and dried in the air. Vacuum drying at 50° C. to obtain the finished polyethylene-methacrylic acid-polyvinylamine fiber of the porous fibrous absorbent material. Its physical and chemical properties are as follows:

[0050]

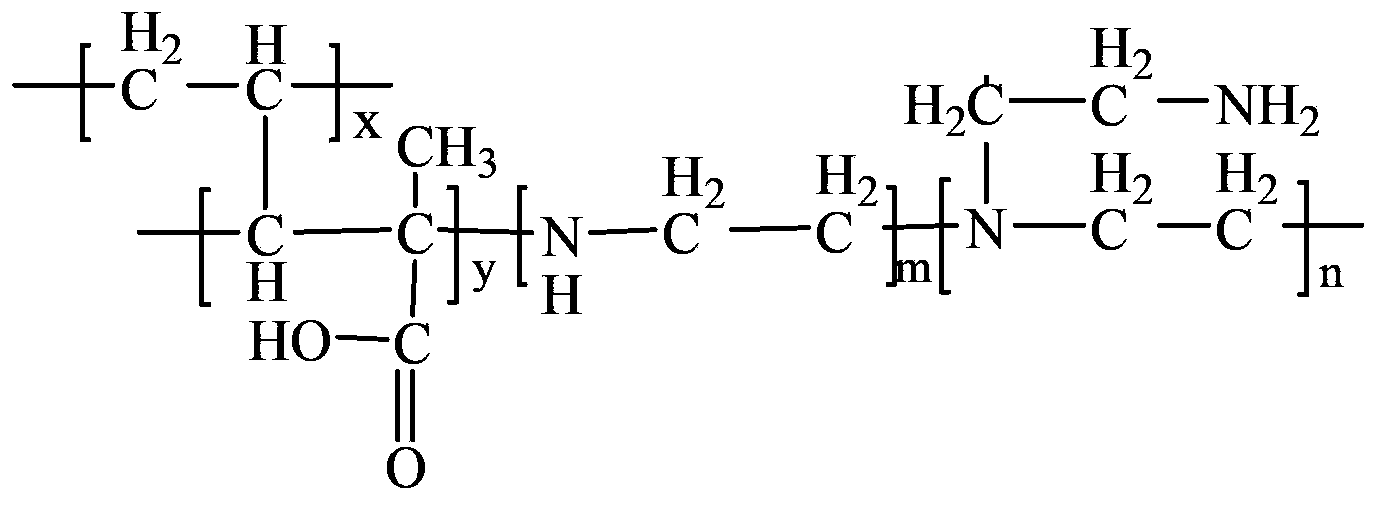

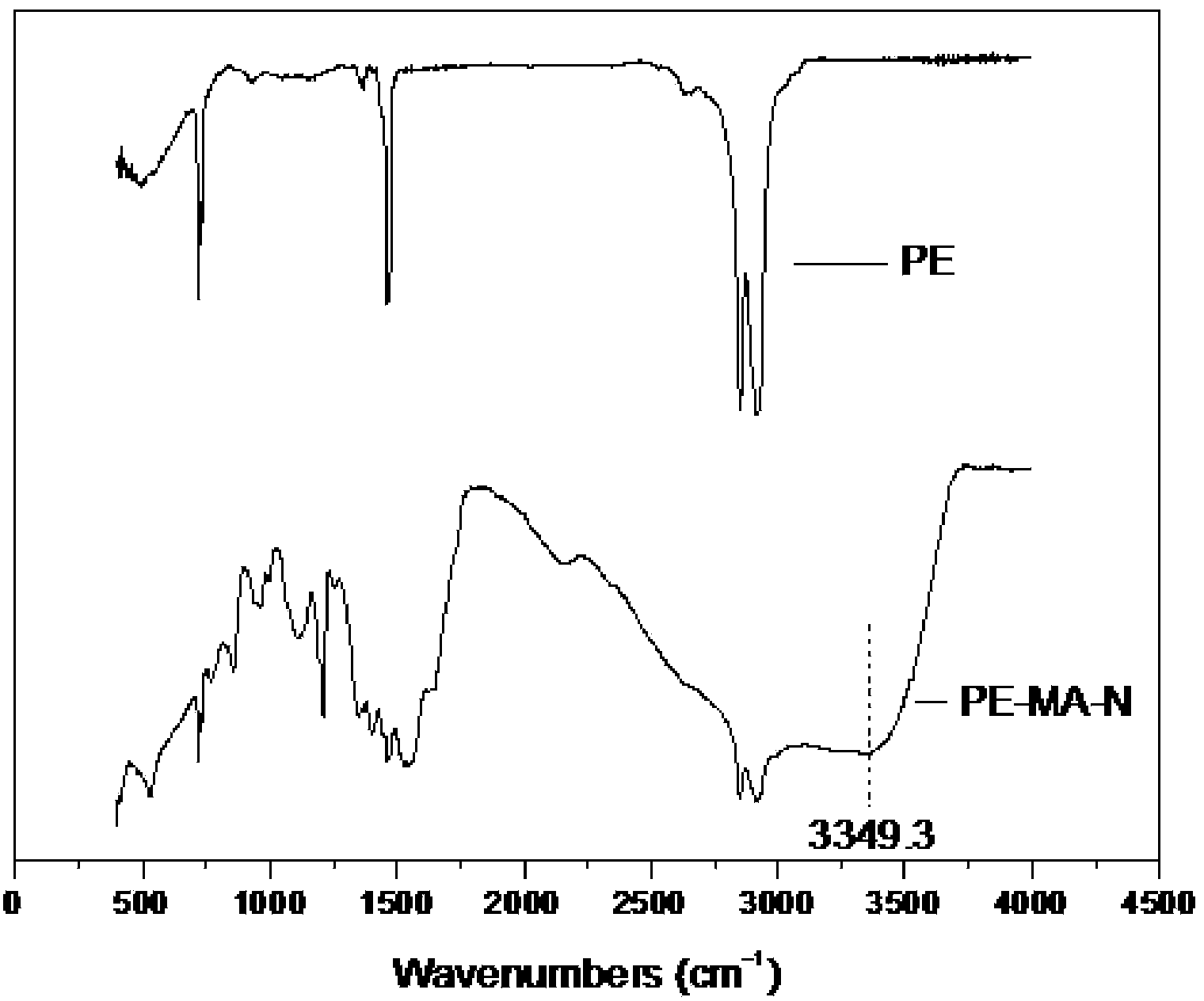

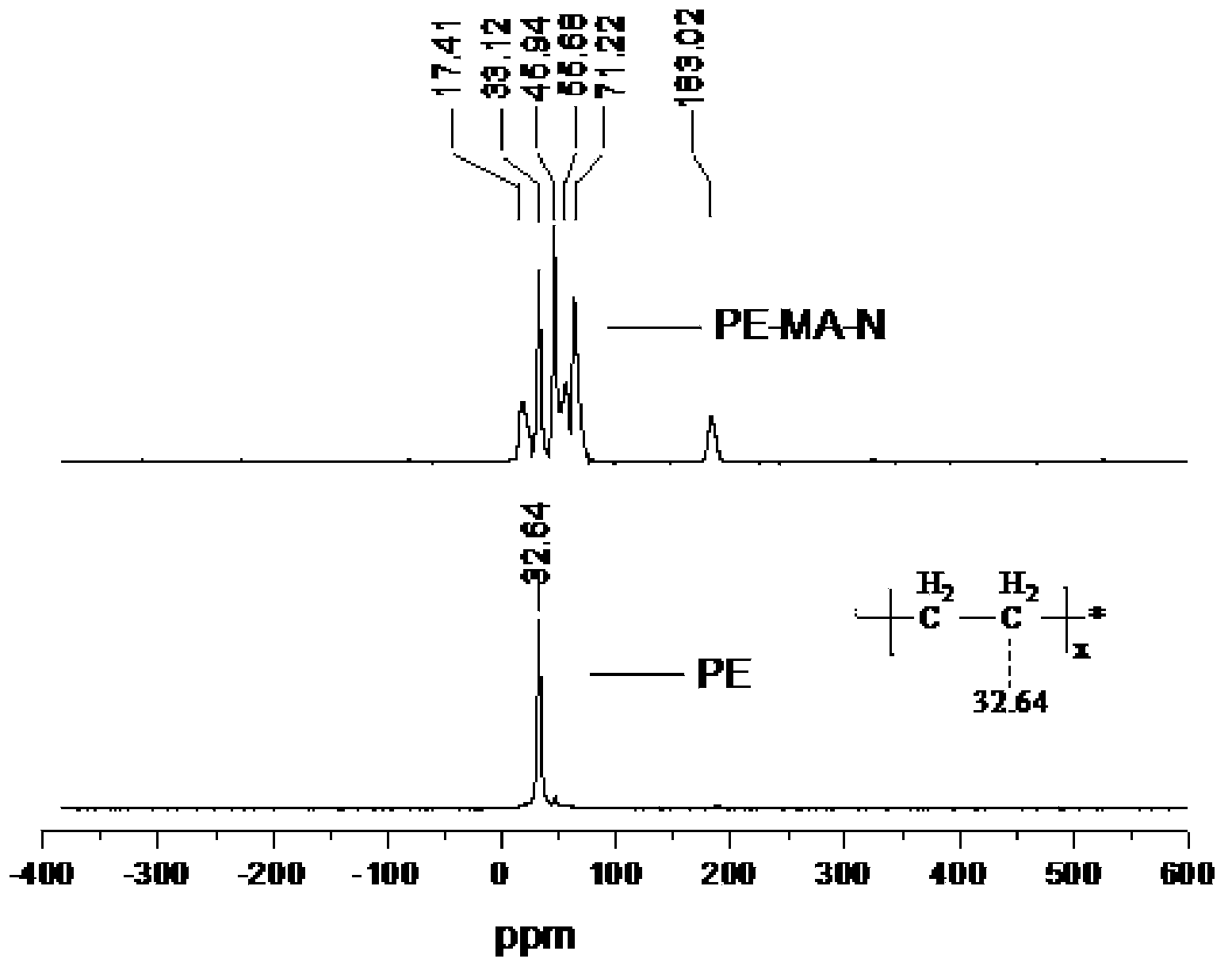

[0051] The prepared fiber molecular formula is as follows figure 1 ,Such as Image 6 Among them, the fiber skeleton is polyethylene-methacrylic acid, the '-CH-' (2) of methacrylic acid is connected with the '-CH-' (1) of polyethylene chain, and the connection point of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com