Nanofiller modified solvent-free insulating paint and preparation method thereof

A technology of nano-modification and insulating varnish, applied in the direction of polyester coating, coating, etc., can solve the problems of ordinary insulating varnish baking loss and other problems, and achieve the effect of curing and not easy to lose, overcome loss, and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

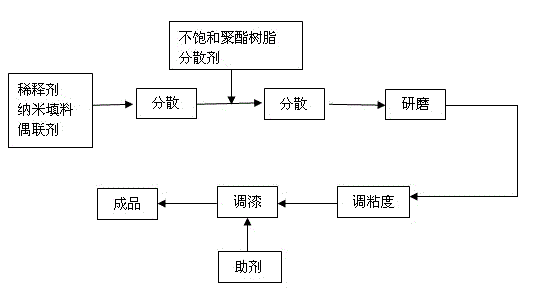

Method used

Image

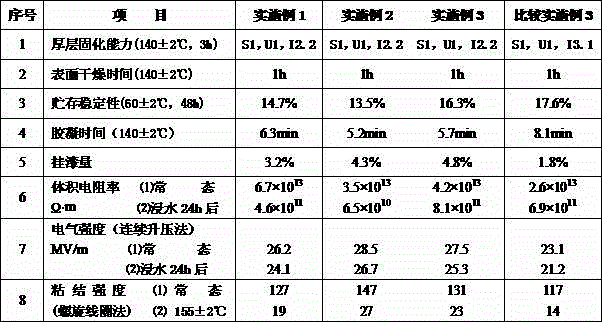

Examples

Embodiment 1

[0028] Embodiment 1 (by weight percentage):

[0029] Heat-resistant unsaturated polyester resin: 70%

[0030] Styrene: 27%

[0031] nano-SiO 2 : 3%

[0032] KH-570: 0.5%

[0033] Dicumyl peroxide 1%

[0034] BYK 220S: 0.3%

[0035] TEGO Flow 370: 0.2%

[0036] BYK 022: 0.1%

[0037] Benzoquinone: 0.02%

[0038] Hydroquinone: 0.03%

[0039] Cobalt naphthenate: 0.02%

Embodiment 2

[0040] Embodiment 2 (by weight percentage):

[0041] Heat-resistant unsaturated polyester resin: 58%

[0042] Diallyl phthalate: 32%

[0043] nano-SiO 2 : 2%

[0044] Nano-TiO 2 : 8%

[0045] KH-570: 1%

[0046] tert-butyl perbenzoate 2%

[0047] Disponer 912: 1%

[0048] BYK 415: 0.3%

[0049] Defom 3100: 0.2%

[0050] o-Toluene Hydroquinone: 0.02%

[0051] Tert-butylcatechol: 0.03%

[0052] Manganese naphthenate: 0.02%

Embodiment 3

[0053] Embodiment 3 (by weight percentage):

[0054] Heat-resistant unsaturated polyester resin: 62%

[0055] Vinyl toluene: 30%

[0056]nano-SiO 2 : 3%

[0057] Nano-Al 2 o 3 : 5%

[0058] KH-570: 1%

[0059] Diphenylene diperoxide 2%

[0060] BYK 180: 0.5%

[0061] Silok 8244: 0.2%

[0062] BYK 017: 0.1%

[0063] Benzoquinone: 0.02%

[0064] Tert-butylcatechol: 0.03%

[0065] Cobalt isooctanoate: 0.02%

[0066] Manganese naphthenate: 0.02%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com