In-water-phase monodisperse sodium yttrium tetrafluoride multi-color luminescent nanoparticle and preparation method thereof

A technology of sodium tetrafluoroyttrium and nanoparticles, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of complexity, particle aggregation and fluorescence weakening, etc., and achieve simple process, extremely biocompatibility, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

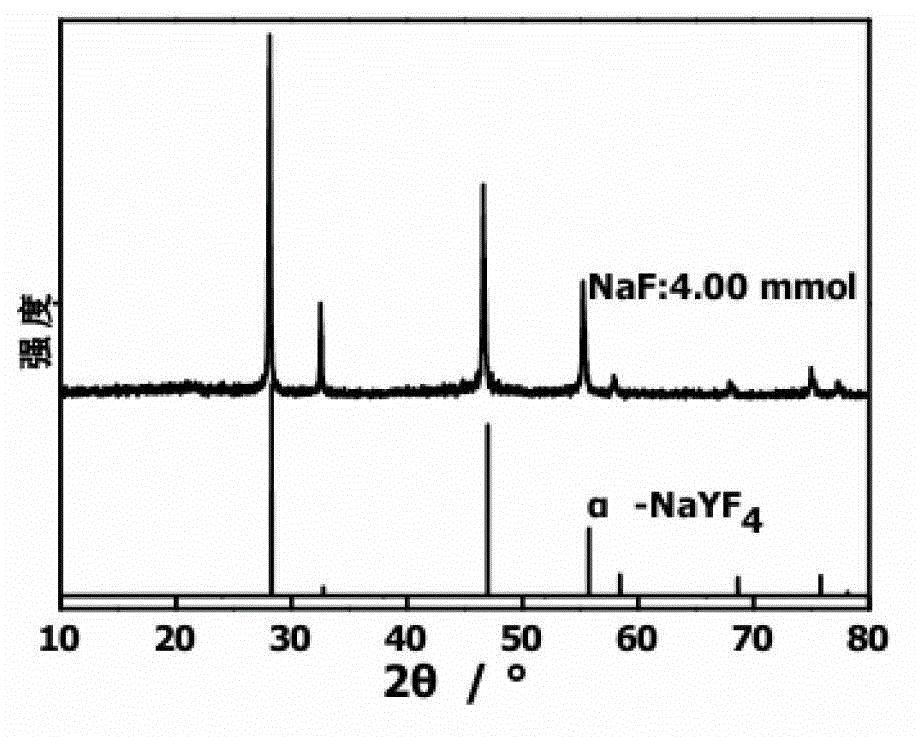

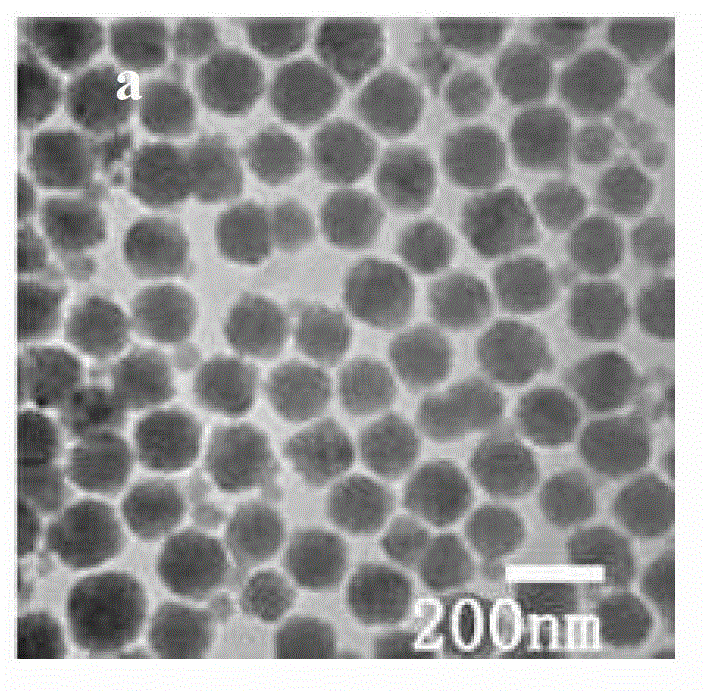

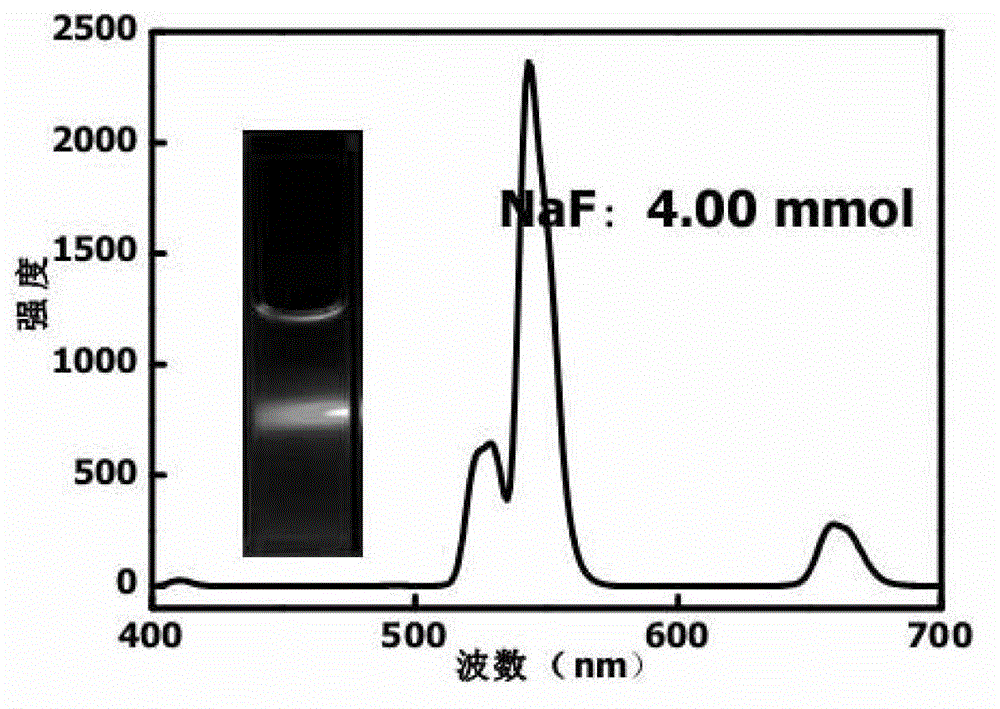

Embodiment 1

[0032] 1. Prepare Y (NO 3 ) 3 , Yb (NO 3 ) 3 , Er (NO 3 ) 3 Rare earth salt solution; prepare a HCl solution with a concentration of 1mol / L; prepare a NaF solution with a concentration of 1mol / L;

[0033] 2. Add 0.1g of polyacrylic acid, 15ml of absolute ethanol, and 10mL of ethylene glycol to the reaction kettle in sequence, and stir until the solution is uniform;

[0034] 3. Continue to add 1.7ml of Y (NO 3 ) 3 Rare earth salt solution, 200 μl of Yb (NO 3 ) 3 Rare earth salt solution, 100 μl of Er(NO 3 ) 3 Rare earth salt solution, stirred for 10 minutes;

[0035] 4. Then add 4mL NaF solution to the reaction kettle, add slowly dropwise, and stir evenly;

[0036] 5. Finally, 600 μl of HCl solution was added to the solution, and magnetically stirred for 10 minutes;

[0037] 6. The reaction kettle was reacted at 190°C for 72 hours, cooled naturally, washed with deionized water, the solvent in the product was removed, and the product was dispersed with 4ml of deio...

Embodiment 2

[0039] 1. Prepare Y (NO 3 ) 3 , Yb (NO 3) 3 , Er (NO 3 ) 3 Rare earth salt solution; prepare a HCl solution with a concentration of 1mol / L; prepare a NaF solution with a concentration of 1mol / L;

[0040] 2. Add 0.1g of polyacrylic acid, 15ml of absolute ethanol, and 10mL of ethylene glycol to the reaction kettle in sequence, and stir until the solution is uniform;

[0041] 3. Continue to add 1.7ml of Y (NO 3 ) 3 Rare earth salt solution, 200 μl of Yb (NO 3 ) 3 Rare earth salt solution, 100 μl of Er(NO 3 ) 3 Rare earth salt solution, stirred for 10 minutes;

[0042] 4. Then add 6mL NaF solution to the reaction kettle, add slowly dropwise, and stir evenly;

[0043] 5. Finally, 600 μl of HCl solution was added to the solution, and magnetically stirred for 10 minutes;

[0044] 6. The reaction kettle was reacted at 190°C for 72 hours, cooled naturally, washed with deionized water, the solvent in the product was removed, and the product was dispersed with 4ml of deion...

Embodiment 3

[0046] 1. Prepare Y (NO 3 ) 3 , Yb (NO 3 ) 3 , Er (NO 3 ) 3 Rare earth salt solution; prepare a HCl solution with a concentration of 1mol / L; prepare a NaF solution with a concentration of 1mol / L;

[0047] 2. Add 15ml of absolute ethanol and 10mL of ethylene glycol to the reaction kettle in sequence, and stir until the solution is uniform;

[0048] 3. Continue to add 1.7ml of Y (NO 3 ) 3 Rare earth salt solution, 200 μl of Yb (NO 3 ) 3 Rare earth salt solution, 100 μl of Er(NO 3 ) 3 Rare earth salt solution, stirred for 10 minutes;

[0049] 4. Then add 4.35mL NaF solution to the reaction kettle, slowly add dropwise, and stir evenly;

[0050] 5. Finally, 600 μl of HCl solution was added to the solution, and magnetically stirred for 10 minutes;

[0051] 6. The reaction kettle was reacted at 190°C for 24 hours, and after natural cooling, it was centrifugally washed with deionized water, the solvent in the product was removed, and the product was dispersed with 4ml o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com