Production method of lightly grinded nutritional rice with good cooking performance and storability

A nutritious rice and cooking technology, which is applied in the fields of heat preservation of seeds, edible seeds preservation, preservation of seeds by radiation/electric treatment, etc., can solve the problems of short storage period and poor cooking performance of brown rice, and improve the cooking performance. , Improve the killing effect and reduce the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] (1) Use a 60-mesh fine sand roller to lightly mill the brown rice at a low speed (the spindle speed is 1000 rpm), remove the floating chaff on the surface of the rice grains with a brush polishing wheel, and obtain a lightly milled nutritious rice with a reduction rate of 5%; (2 ) Slowly add water by atomization until the water content of lightly milled nutritious rice is 20%, maintain a water addition rate of 0.6% / hour before the water reaches 17%, and slowly increase the water addition rate to 1.0% / hour after exceeding 17%; ( 3) Lightly mill the nutritious rice with microwave treatment, the microwave frequency is 2450±50MHz, the power is 300 watts, and the processing time is 30 seconds; (5) Treat the lightly milled nutritious rice with atmospheric pressure superheated steam, the temperature of the superheated steam is 200°C, and the action time is 10 seconds; 3% RH) for 6 months.

Embodiment 2

[0014] (1) Use a 70-mesh fine sand roller to lightly mill the brown rice at a low speed (the spindle speed is 800 rpm), and use a brush polishing wheel to remove the floating bran on the surface of the rice grains to obtain a lightly milled nutritious rice with a reduction rate of 3%; (2 ) Slowly add water by atomization until the water content of lightly milled nutritious rice is 19%, maintain a water adding rate of 0.6% / hour before the water reaches 17%, and slowly increase the water adding rate to 0.9% / hour after exceeding 17%; ( 3) Lightly mill the nutritious rice with microwave treatment, the microwave frequency is 2450±50MHz, the power is 350 watts, and the processing time is 25 seconds; (5) Treat the lightly milled nutritious rice with superheated steam at normal pressure. The temperature of the superheated steam is 160°C, and the action time is 20 seconds; 3% RH) for 6 months.

Embodiment 3

[0016] (1) Use an 80-mesh fine sand roller to lightly mill the brown rice at a low speed (the spindle speed is 600 rpm), and use a brush polishing wheel to remove the floating bran on the surface of the rice grains to obtain lightly milled nutritional rice with a reduction rate of 2%; (2 ) Slowly add water by atomization until the water content of lightly milled nutrient rice is 18%, maintain a water addition rate of 0.6% / hour before the water content reaches 17%, and slowly increase the water addition rate to 0.8% / hour after exceeding 17%; ( 3) Lightly mill the nutritious rice by microwave treatment, the microwave frequency is 2450±50MHz, the power is 400 watts, and the processing time is 20 seconds; (5) Treat the lightly milled nutritious rice with atmospheric pressure superheated steam, the temperature of the superheated steam is 120°C, and the action time is 30 seconds; 3% RH) for 6 months.

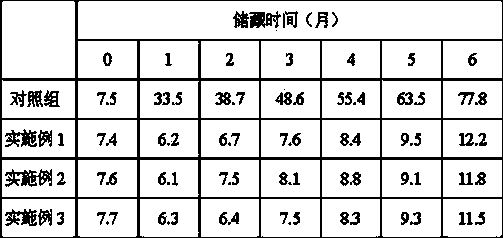

[0017] Effectiveness analysis:

[0018] (1) Physical and chemical indicators of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com