Instant noodle made of Tibetan highland barley and preparation method of noodle

A technology of instant noodles and highland barley, applied in the field of highland barley instant noodles and its preparation, can solve the problems of reducing the nutrient content of highland barley instant noodles and increasing the production cost of highland barley instant noodles, and achieve the effect of soft and smooth taste and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

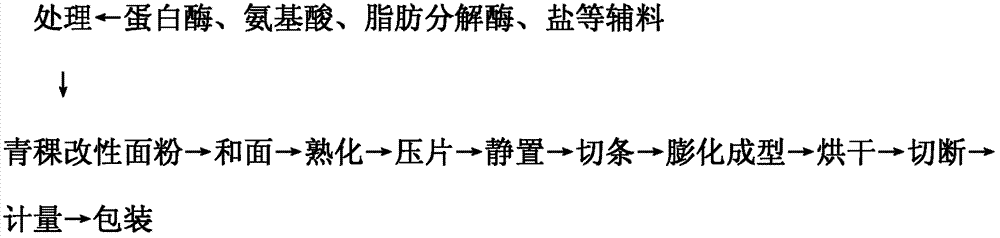

Image

Examples

Embodiment 1

[0028] Components Highland barley modified flour Modified starch Bone powder Magic Yu powder

[0029] 1 90% 5% 1% 4%

[0030] Highland barley modified flour is produced as follows: highland barley flour is crushed to about 40 meshes, 40% (mass content, the same below) of warm water at 40°C to 45°C is added, protease 9%, pentosanase 7%, fat decomposition Enzyme 5%, salt 1%-1.5%, after 36 hours of bio-enzyme at room temperature, drench off the enzyme liquid on the surface of barley powder, dry until the water content is lower than 5%, and finely grind to 100 mesh, the product can be used Highland barley modified flour for making highland barley instant noodles.

[0031] When producing instant noodles, add 5% vinegar starch to the highland barley modified flour and mix well. In the aging stage, add 1% bone powder and 4% konjac powder, and then ripen, press into tablets, stand still, and cut into strips. Highland barley noodle cakes are prepared through the modern non-fried inst...

Embodiment 2

[0033] Components Highland barley modified flour Modified starch Bone powder Magic Yu powder

[0034] 2 85% 5% 2% 8%

[0035]Highland barley modified flour is produced as follows: highland barley powder is crushed to about 40 meshes, added with 40% warm water at 40°C to 45°C, added with 6% protease, 5% pentosanase, 6% lipolytic enzyme, and 1% salt -1.5%, after 36 hours of bio-enzymeization at room temperature, the enzyme liquid on the surface of the highland barley powder is drenched, dried until the water content is lower than 5%, and finely crushed to 100 meshes to obtain highland barley powder that can be used to make highland barley instant noodles. Sexual flour.

[0036] When producing instant noodles, add 5% vinegar starch into the modified highland barley flour and mix well. In the ripening stage, add 2% bone powder and 8% konjac powder. After ripening, tableting, standing, cutting Highland barley noodle cakes are prepared through modern non-fried instant noodle proce...

Embodiment 3

[0038] Components Highland barley modified flour Modified starch

[0039] 3 94% 6%

[0040] Highland barley modified flour is produced as follows: ground highland barley powder to about 40 mesh, add 40% of warm water at 40°C to 45°C, add 7% protease, 6% pentosanase, 5% lipolytic enzyme, and 1% salt -1.5%, after 36 hours of bio-enzymeization at room temperature, the enzyme liquid on the surface of the highland barley powder is drenched, dried until the water content is lower than 5%, and finely crushed to 100 meshes to obtain highland barley powder that can be used to make highland barley instant noodles. Sexual flour.

[0041] When producing instant noodles, highland barley modified flour and vinegar starch are added and mixed well, and the highland barley noodle cake is obtained through modern non-fried instant noodle process steps such as ripening, sheeting, standing, cutting into strips, puffing and drying. The highland barley instant noodles prepared in this embodiment h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com