Load type CoB catalyst for process of preparing hydrogen through hydrolysis of sodium borohydride and preparation method of load type CoB catalyst

A technology for producing hydrogen and sodium borohydride by hydrolysis, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problem of unsatisfactory stability and reusability, The weak binding force between the active component and the carrier, the decline of catalyst activity, etc., achieve the effect of good reusability, good dispersibility, and catalytic activity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

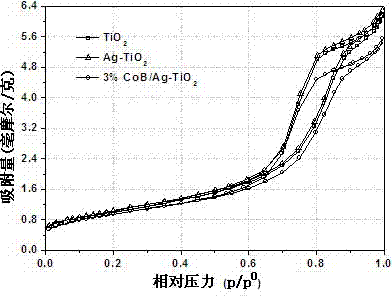

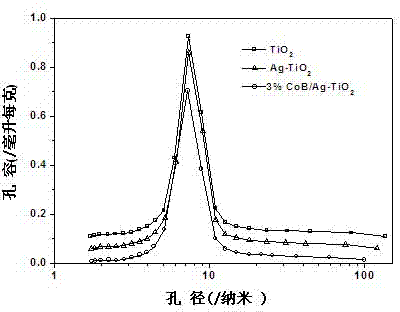

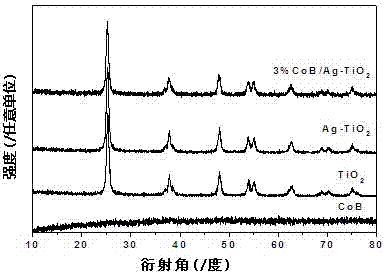

[0038] [Example 1] A supported CoB catalyst for hydrogen production by hydrolysis of sodium borohydride and its preparation method (the mass percentage of Co is 3%)

[0039] Prepare a sensitizer solution with the following composition:

[0040] Silver nitrate (AgNO 3 ) concentration is 2.8×10 -4 mol / L, ammonia water (NH 3 ·H 2 O) the concentration is 5×10 -3 mol / L, the concentration of formaldehyde (HCHO) is 1.6×10 -4 mol / L. And carefully adjust the pH of the sensitizer solution to 11 with 0.2mol / L NaOH solution. Weigh 1g TiO 2 The carrier (Nanjing Tianxing New Material Co., Ltd., anatase crystal form, specific surface area of 81.6 square meters per gram) was added to 70 mL of the above sensitizer solution, slowly heated to 40° C., stirred for 4 hours, and then filtered. The product was washed with pure water and dried at 90°C for 4 hours to obtain the sensitized carrier. Add 1 g of the sensitized carrier to 20 mL of electroless plating solution, stir at 25 °C for 1...

Embodiment 2

[0045] [Example 2] A supported CoB catalyst for hydrogen production by hydrolysis of sodium borohydride and its preparation method (the mass percentage of Co is 1%)

[0046] In the electroless plating solution of the present embodiment, cobalt acetate (Co(Ac) 2 4H 2 (0) concentration is 0.003mol / L, and other operations are with embodiment 1. The ICP test shows that the actual loading of the active component Co in the catalyst is 0.99% by mass, and the content of silver is 0.2% by mass.

[0047] The prepared catalyst of embodiment 2 is carried out activity test, and its result is as Figure 4 As shown, the catalyst for 1wt.% NaBH at 20°C 4 (+5wt.%NaOH) aqueous solution can produce hydrogen at a rate of 4692mL / (min·g -1 Co).

Embodiment 3

[0048] [Example 3] A supported CoB catalyst for hydrogen production by hydrolysis of sodium borohydride and its preparation method (the mass percentage of Co is 15%)

[0049] In the electroless plating solution of the present embodiment, cobalt acetate (Co(Ac) 2 4H 2 (0) concentration is 0.045mol / L, and other operations are with embodiment 1. The ICP test shows that the actual loading of the active component Co in the catalyst is 7.8% by mass, and the content of silver is 0.15% by mass.

[0050] The prepared catalyst of embodiment 2 is carried out activity test, and its result is as Figure 4 As shown, the catalyst for 1wt.% NaBH at 20°C 4 (+5wt.%NaOH) aqueous solution can produce hydrogen at a rate of 4638mL / (min·g -1 Co).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com