Tube shell for vacuum package of micro-optical-electronic-mechanic system and manufacture method thereof

A technology of micro-opto-electromechanical system and vacuum packaging, which is applied in the process of producing decorative surface effects, micro-structure devices, and manufacturing micro-structure devices, etc., which can solve the problems of difficult detection, affecting welding air tightness, and low welding efficiency, etc. problem, to avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

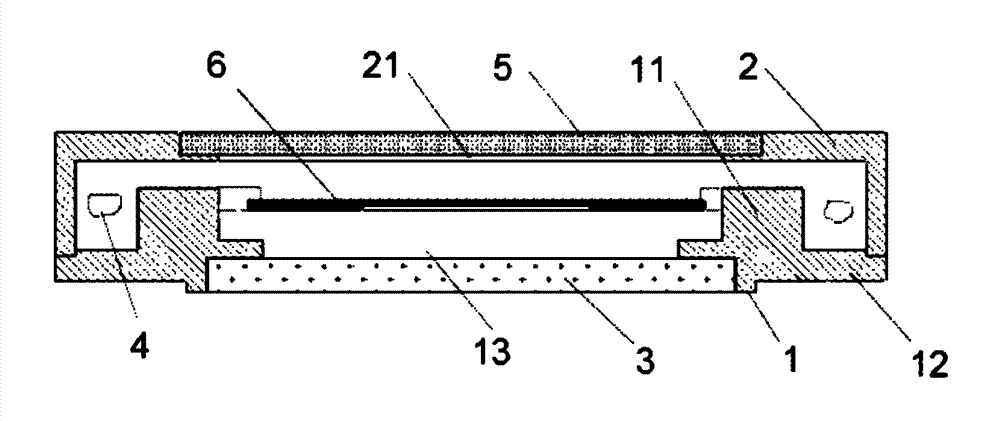

[0031] Embodiment: A tube shell for micro-opto-electromechanical system vacuum packaging, including a base 1, a sealing cap 2, an optical filter 3 and a getter fixing device 4, and a ring is arranged on the inside of one end of the base 1 in a hollow cylindrical structure chip fixing groove, a ring-shaped outer expansion stopper 12 is arranged on the outer wall of the base circumference, the sealing cap 2 covers the outer side of one end of the base 1 and is sealed and fixed with the annular outer expansion stopper 12 on the base, and the other end of the base 1 is provided with There is an opening 13 communicating with the internal space, and the optical filter 3 is sealed and fixedly covered on the outer end surface of the opening 13. The axial end surface of the sealing cap 2 is provided with a light-transmitting window 21 communicating with the interior of the base 1, and a transparent window 21 is also provided. The light sheet 5, the light-transmitting sheet 5 is sealed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com