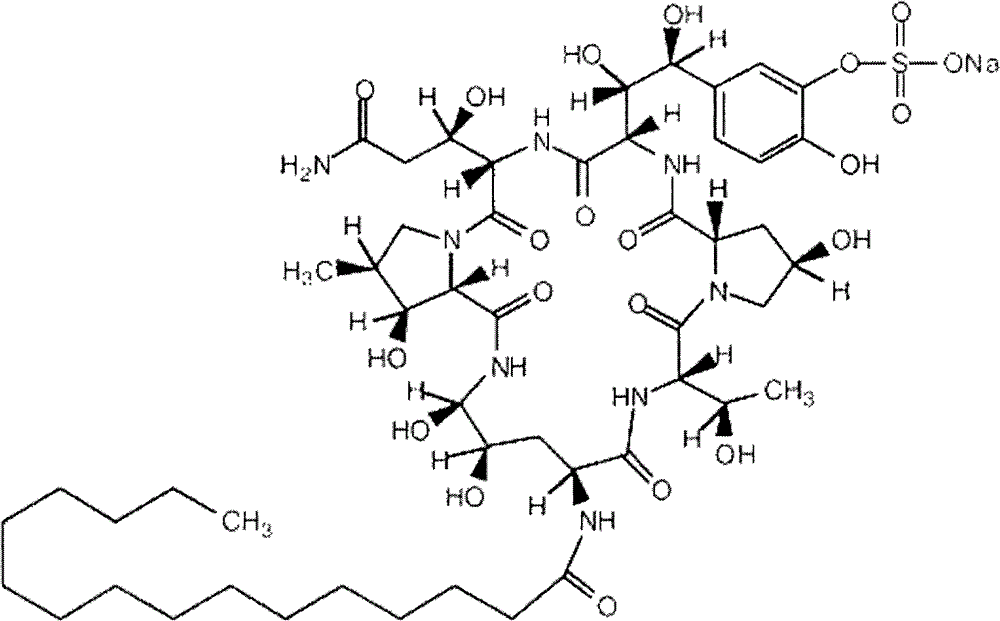

A kind of preparation method of high-purity micafungin precursor compound

A precursor compound, micafungin technology, applied in the direction of peptides, etc., can solve the problems of extraction and purification that have not been reported, and achieve the effects of controllable quality, simple process and high sample purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

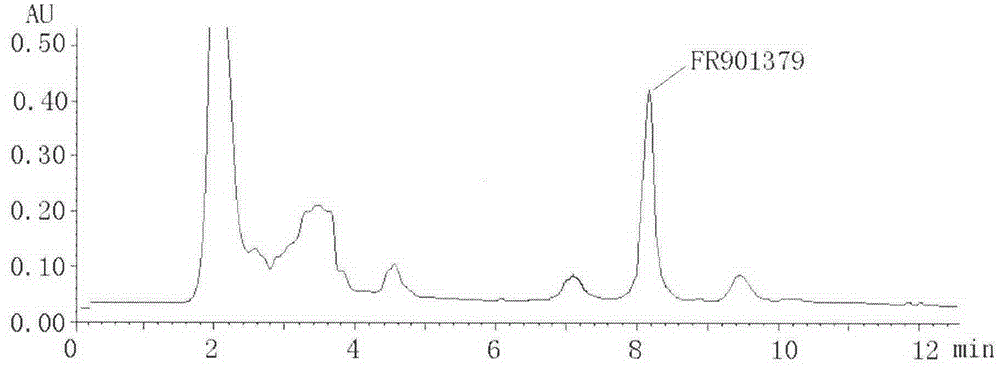

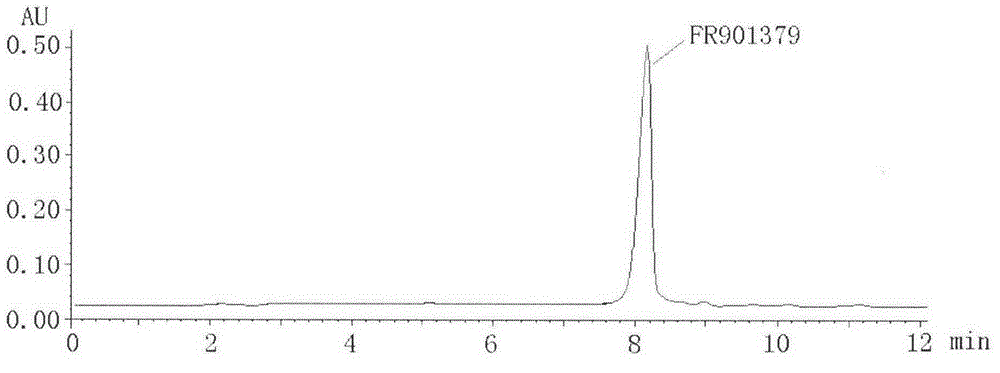

[0033] Take 5.0L of micafungin precursor compound FR901379 fermentation broth, the fermentation unit is 1320μg / mL, and suction-filter to obtain 1.1kg of solid-state fermentation culture, add 1.25L of 95% ethanol, stir and extract at room temperature for 60min, suction-filter, and collect the filtrate. Add 1 L of 95% ethanol to the filter cake, stir at room temperature for 30 minutes, vacuum filter, and combine the filtrate (see attached figure 1) , add water to adjust the ethanol concentration to 30%, adsorb with 800mL D312 resin, wash 2400mL with 50% ethanol, elute with 80% ethanol until the elution of FR901379 is completed, and concentrate the 80% ethanol eluate to ethanol under reduced pressure at 40°C The concentration was less than 2%, cooled to 20°C, suction filtered, and vacuum-dried at 40°C to obtain 7.16g of crude extract of FR901379, which was dry-loaded on a 500mL silica gel column and eluted with ethyl acetate-petroleum ether 7;3, HPLC Detection, combined area per...

Embodiment 2

[0035] Take 10.0L of micafungin precursor compound FR901379 fermentation broth, the fermentation unit is 1140μg / mL, and filter to obtain 2.1kg of solid fermentation broth culture, add 3.0L of 95% ethanol, stir and extract at room temperature for 90min, filter with suction, and collect the filtrate (with attached Figure 1 Peak shape similar), add 2.0L concentration of 95% ethanol to the filter cake, vacuum filter after stirring at room temperature for 60min, combine the filtrate, add water to adjust the concentration of ethanol to 35%, adsorb with 1200mLHZ-816 resin, wash 1200mL with 50% concentration of methanol , eluted with 85% concentration of methanol until the elution of FR901379 is completed, the 85% methanol eluate is concentrated under reduced pressure at 40°C to a methanol concentration of less than 2%, cooled to 20°C, suction filtered, and vacuum-dried at 40°C to obtain rice 12.63 g of crude extract of cafungin precursor compound FR901379. Load the sample on a 700m...

Embodiment 3

[0037] Take 8.0L of micafungin precursor compound FR901379 fermentation broth, the fermentation unit is 1260μg / mL, and suction filter to obtain 1.4kg of solid fermentation broth culture, add methanol 4L, stir and extract at room temperature for 30min, suction filtration, collect the filtrate, filter cake Add 2L of methanol, stir at room temperature for 30min, then vacuum filter, and combine the filtrate (with the attached Figure 1 Peaksimilar in shape), add water to adjust the concentration of methanol to 40%, adsorb with 1200mL D312 resin, wash 2000mL with 50% concentration of methanol, and elute with 80% concentration of methanol until the elution of FR901379 is completed. Concentrate until the concentration of methanol is less than 2%, cool to 20°C, filter with suction, and dry under vacuum at 40°C to obtain 9.45 g of crude extract of FR901379. Load the sample on a 500mL silica gel column by dry method, elute with acetone-petroleum ether 6;4, detect by HPLC, combine the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com