Electric desalting and dewatering method

A technology of electric desalination, dehydration and water injection, which is applied in the directions of electric/magnetic dehydration/demulsification, chemical dehydration/demulsification, electric/magnetic refining, etc. Solve problems such as high salt water content, achieve the effect of reducing oil content in drainage, low oil content in drainage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix 98% by weight of Luning pipeline crude oil and 2% by weight of water with 5ppm demulsifier AE1910, and pass through the microwave radiation area, where the microwave radiation temperature is 50°C, the radiation time is 5min, and the microwave power is 1000W. After microwave treatment, it enters the electric desalination First-level electrical desalting was carried out in the tank (desalting and dehydration conditions: temperature 110°C, residence time 15 minutes, number of oscillations 200 times, electric field strength 800V / cm), and then the desalted crude oil was taken to analyze the salt and water content. Then keep other conditions unchanged, change the microwave power to 800W, 600W, 400W, 200W respectively, the test results are shown in Table 2.

[0019] Table 2 Results of desalting and dehydration of crude oil transported by Luning pipeline

[0020] serial number

Embodiment 2

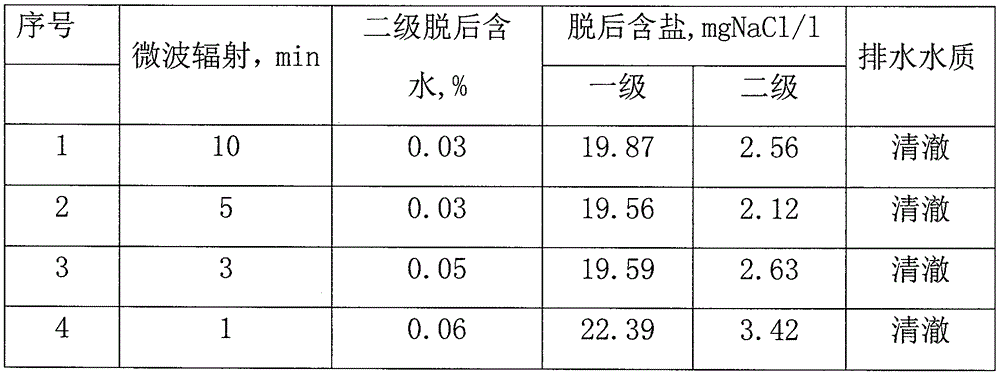

[0022] Mix 94% by weight of Puyang mixed crude oil and 6% by weight of water with 10ppm demulsifier FC961, pass through the microwave radiation area, where the microwave radiation temperature is 80°C, the microwave power is 400W, and the radiation time is 30s. After microwave treatment, it enters the electric desalination tank Secondary electric desalting is carried out in the medium, desalination and dehydration conditions: temperature 120°C, residence time 20min, number of oscillations 200 times, electric field strength 800V / cm, and then take the crude oil after desalination to analyze the salt and water content. Then keep other conditions unchanged, change the microwave radiation time to 10min, 5min, 3min, 1min respectively, the test results are shown in Table 3.

[0023] Table 3 Desalting and dehydration results of Puyang blended crude oil

[0024]

Embodiment 3

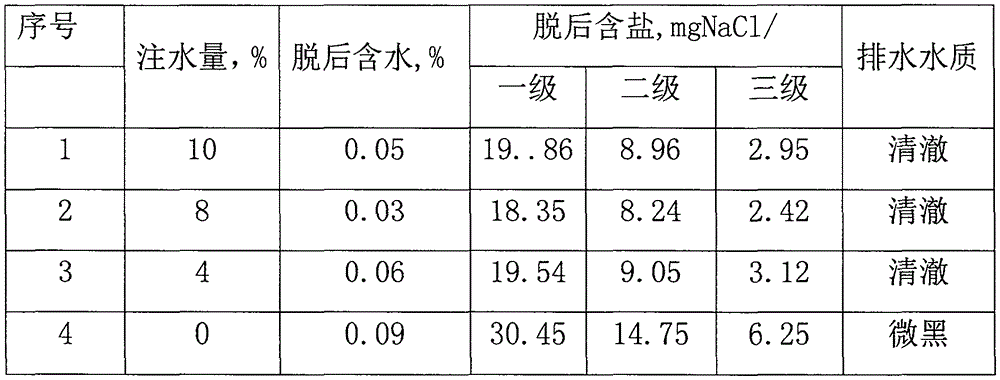

[0026] Mix 88% by weight of Puyang mixed crude oil and 12% by weight of water with 200ppm demulsifier ERI 1160, pass through the microwave radiation area, where the microwave radiation temperature is 130°C, the microwave power is 800W, and the radiation time is 10min. After microwave treatment, it enters the electric desalination Three-stage electric desalting was carried out in the tank (desalting and dehydrating conditions: temperature 130°C, residence time 20 min, number of oscillations 200 times, electric field strength 800V / cm), and then the desalted crude oil was taken to analyze the salt and water content. Then keep other conditions unchanged, and change the water injection volume to 8%, 4%, 0% respectively. The test results are shown in Table 4.

[0027] Table 4 Desalting and dehydration results of Tahe crude oil

[0028]

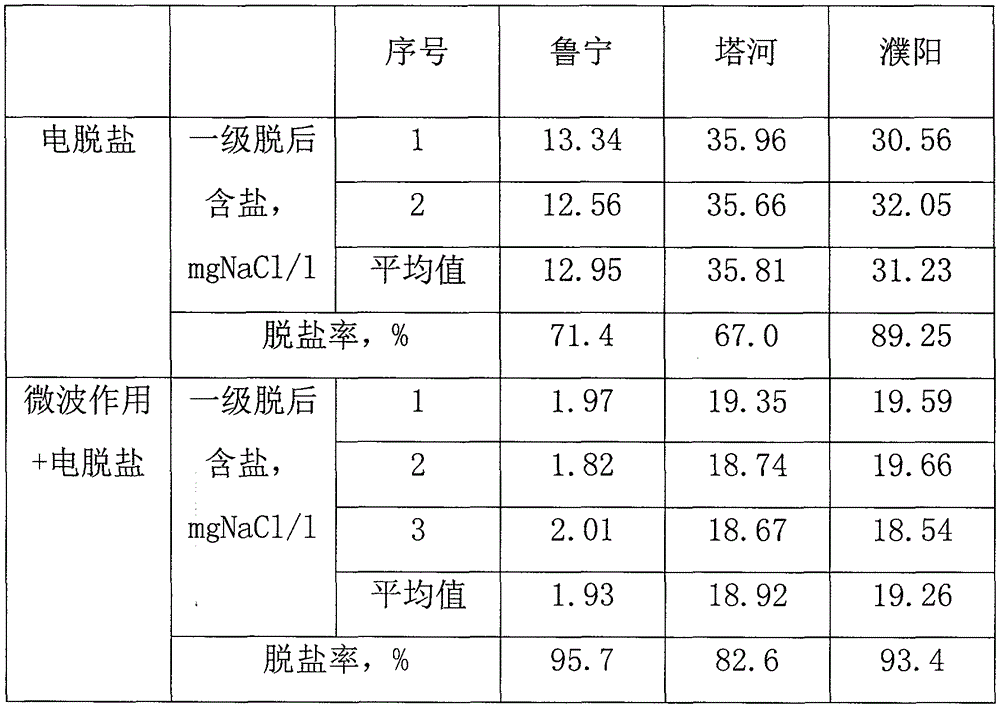

[0029] From the test results of Examples 1 to 3, with the desalination and dehydration method of the present invention, the three crude oils wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com