Double closed-loop control system of permanent-magnet synchronous motor

A permanent magnet synchronous motor and double closed-loop control technology, which is applied in the control system, vector control system, motor generator control, etc., can solve problems such as difficulty in ensuring complete decoupling, large dependence on motor parameters, and reduced system speed regulation performance , to achieve good scalability, high control accuracy and anti-interference ability, and improve the effect of response speed and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

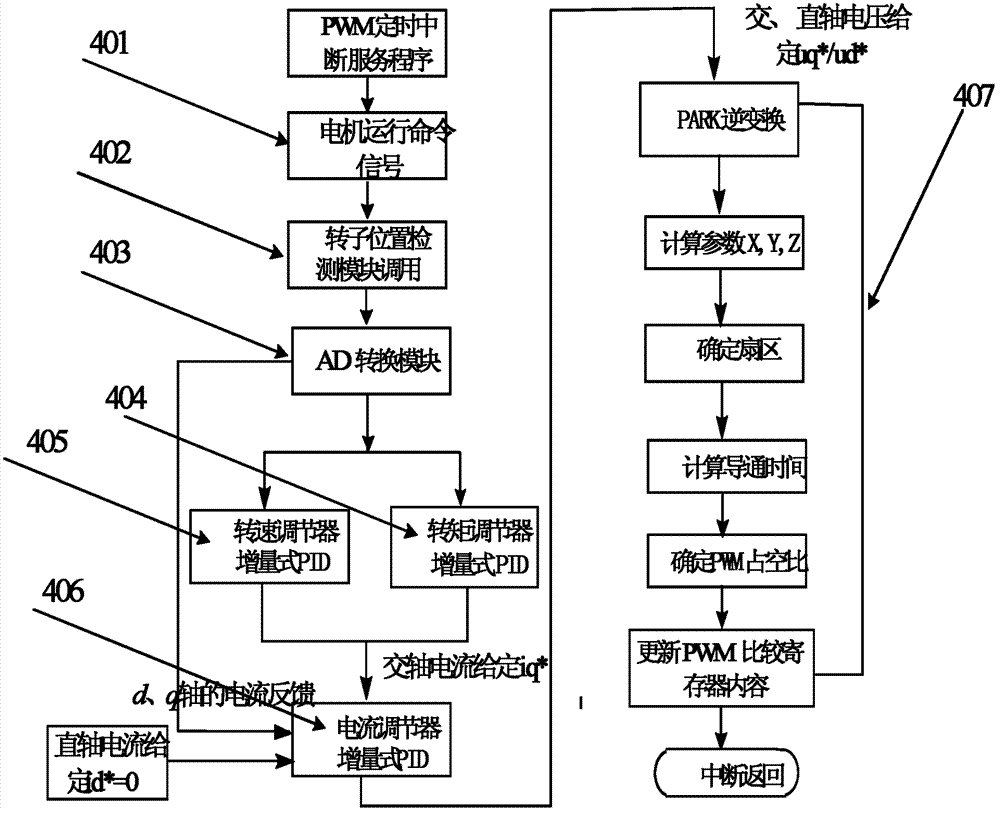

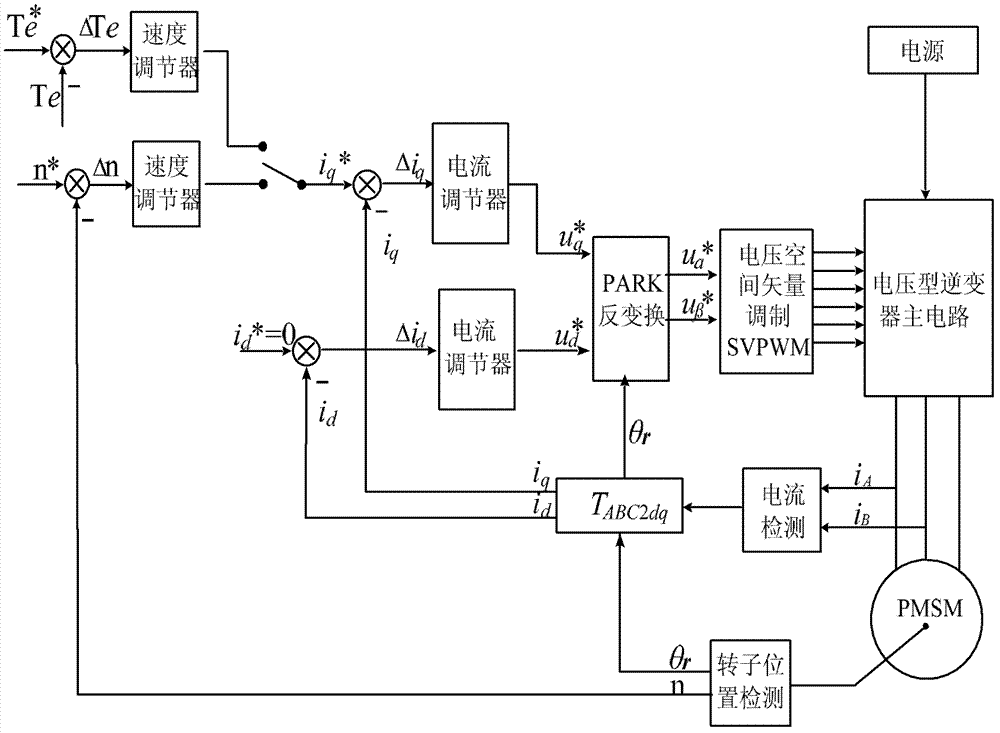

[0019] figure 1 Shown is the subroutine block diagram of the PWM timing interrupt service of the present invention. The PWM timing interrupt program is the main body of the control software, written according to the control structure and control algorithm of the designed control system, and realizes all the main functions of the present invention. figure 2 It is a structure diagram of the control system of the present invention, describing the current, speed (or torque) double closed-loop structure, the input and output of the current controller and the speed controller, vector control and SVPWM modulation. The following combination figure 2 right figure 1 Each step is described in detail:

[0020] In step 401, the motor command signal (running, stopping, turning, etc.) is determined according to the motor control command and the motor running state detection signal.

[0021] In step 402, the rotor position detection module is called, and the rotor position detection mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com