Process for production of aqueous refined sugar solution

A manufacturing method and solution technology, applied in sugar production, sugar juice purification, monosaccharide, etc., can solve the problems of ultrafiltration membrane clogging, difficulty in long-term and stable production of sugar solution, and inability to continuously produce sugar solution in a long-term and stable manner , to improve efficiency and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

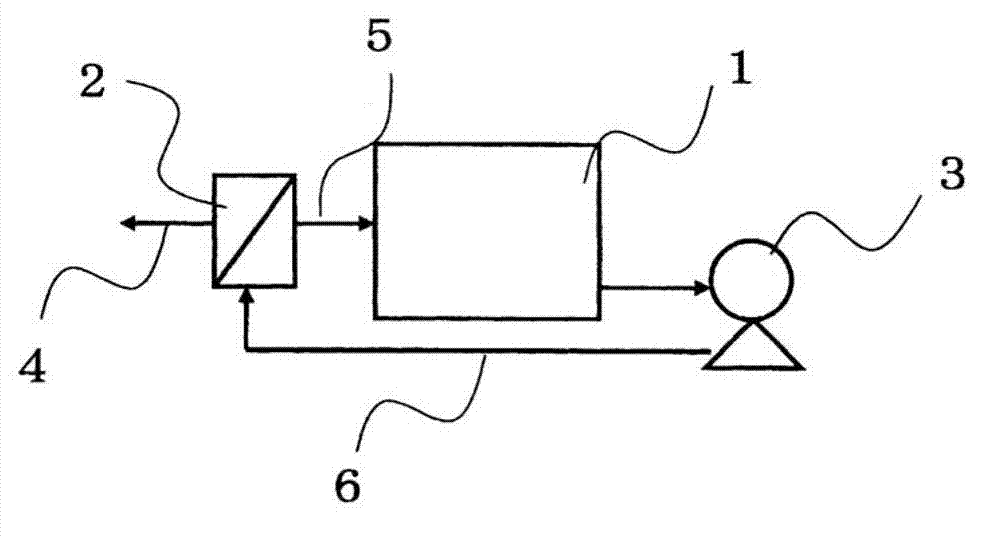

Image

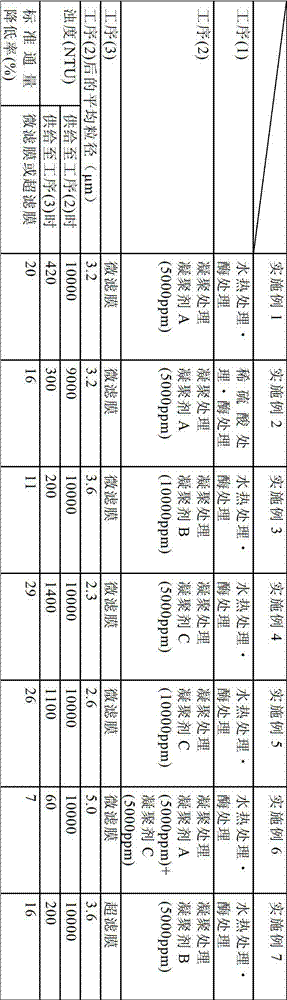

Examples

Embodiment

[0144] Hereinafter, in order to demonstrate the manufacturing method of the refined sugar aqueous solution of this invention in more detail, an Example is given and demonstrated. However, the present invention is not limited to these Examples.

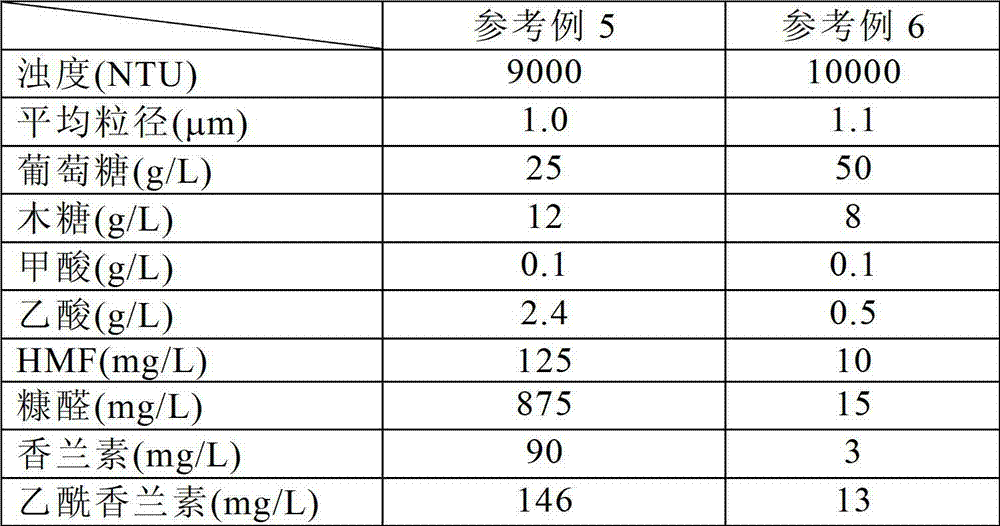

reference example 1)

[0145] (Reference example 1) Method for determining the average particle size by particle size distribution measurement

[0146] The particle size distribution was measured using ELS-8000 manufactured by Otsuka Electronics Co., Ltd., and the average particle size was obtained by obtaining an arithmetic mean value from the particle size values and scattering intensity of the obtained scattering intensity distribution histogram.

[0147] In the present example and the comparative example, the preparation of the sample used for the particle size distribution measurement and the injection of the sample into the measurement cell were performed as follows. 100 g of the aqueous sugar solution obtained in each step was allowed to stand for 6 hours. After standing still, a pipette was inserted into the position about 1 cm from the surface of the sugar solution to suck up the sample, and then the sample was slowly poured into the small cell for particle size measurement attached to th...

reference example 2)

[0148] (Reference example 2) Analysis method of monosaccharide concentration

[0149] The concentration of monosaccharides (glucose and xylose) contained in the obtained aqueous sugar solution was quantified by comparing it with a standard sample under the HPLC conditions shown below.

[0150] Column: Luna NH2 (manufactured by Phenomenex)

[0151] Mobile phase: ultrapure water: acetonitrile = 25:75 (flow rate 0.6mL / min)

[0152] Reaction solution: no

[0153] Detection method: RI (differential refractive index)

[0154] Temperature: 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com