Biosensor

A technology of biosensors and electron transfer bodies, which is applied in the field of biosensors and can solve problems such as high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

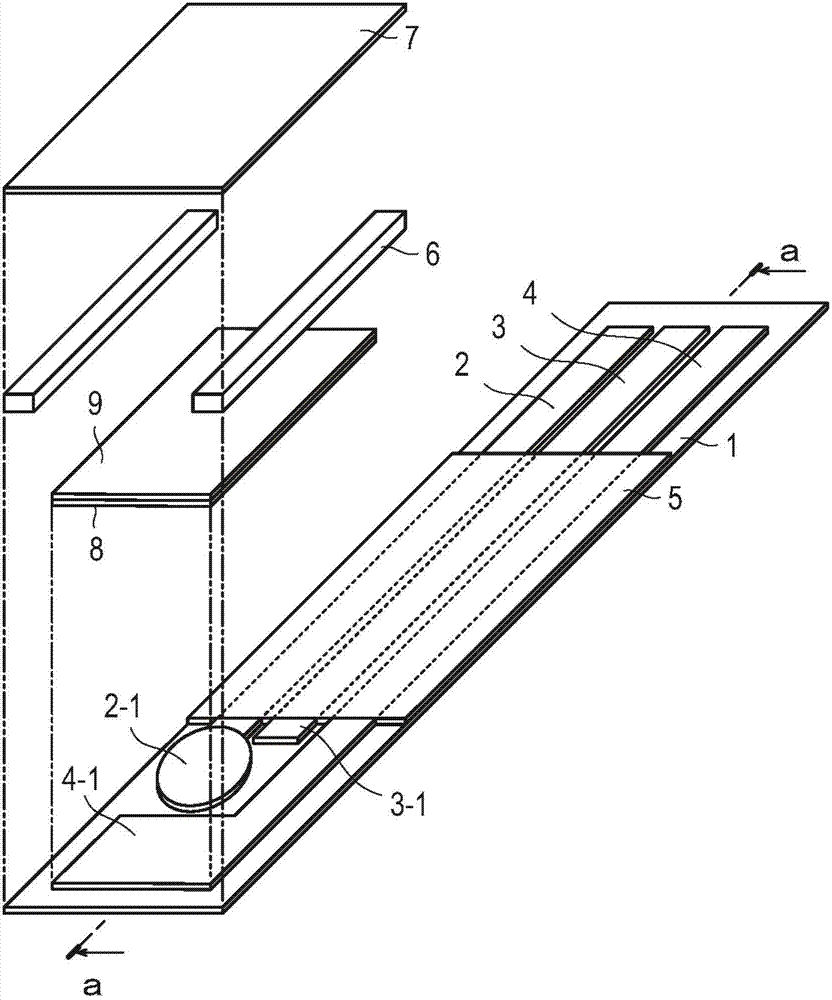

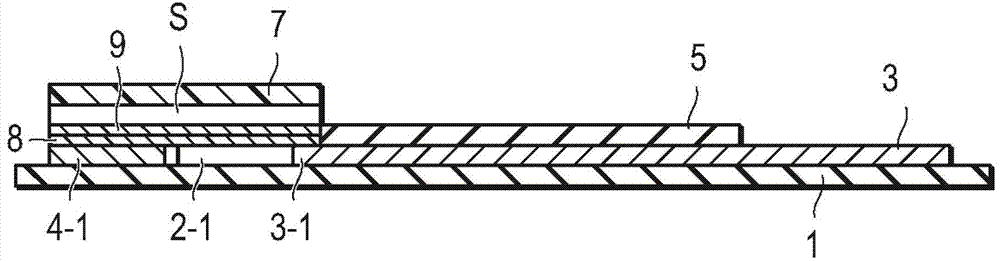

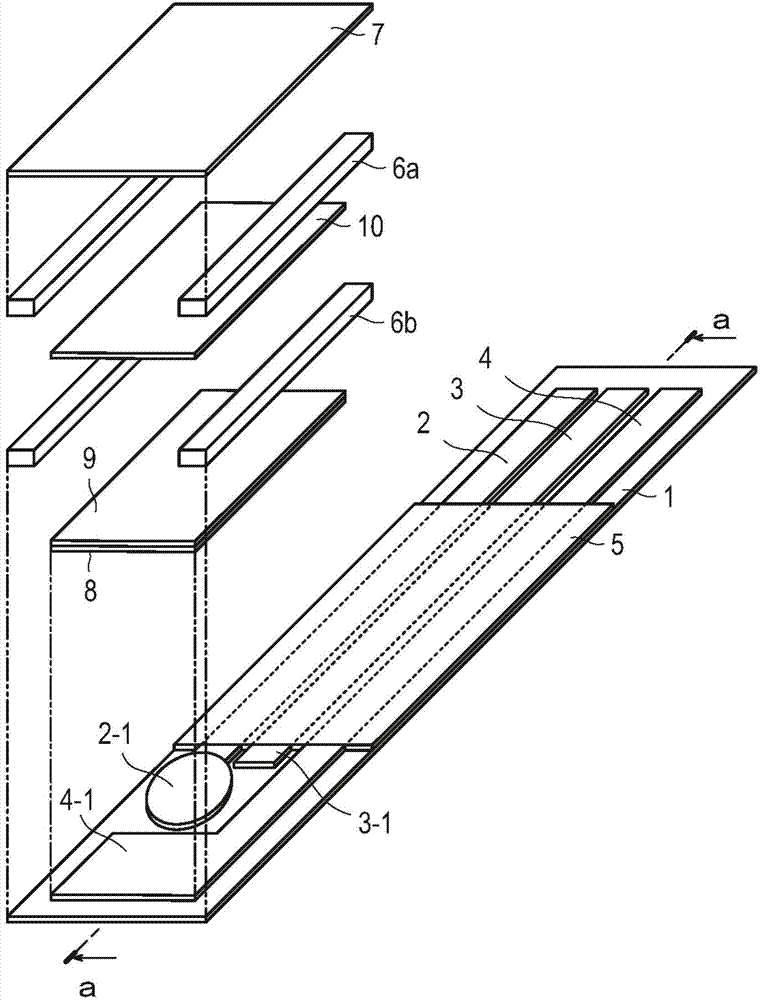

[0158] The electrode used was DEP Chip EP-N (Bio Device Technology Co., Ltd.). DEP Chip EP-N is a working electrode 2 made of carbon, a reference electrode 3, and a counter electrode 4 are respectively formed on an insulating substrate 1, and an insulating layer 5 is sandwiched, and a working electrode part 2 made of carbon is formed- 1. The reference electrode action part 3-1 composed of silver / silver chloride, the counter electrode action part 4-1 of each batch of carbon.

[0159] The first reaction layer (GLDH) was formed in the following steps.

[0160]Per 1 sensor (the amount of supplied sample "whole blood" is 2 μl), mix PQQ-dependent glycerol dehydrogenase at a final concentration of 1.5 U, and 5 mM (0.65 μg) glycylglycine (Wako Pure Chemical Industries, Ltd. ) and 0.025% (0.5 μg) of Emulgen PP-290 (manufactured by Kao Corporation) to obtain a solution (GLDH solution). Add the obtained GLDH solution dropwise in such a way as to cover the working part of the EP-N, the ...

Embodiment 2

[0169] In the same manner as in Example 1 above, the first reaction layer (GLDH layer) was formed.

[0170] The second reaction layer (the LPL layer containing the electron mediator) was formed in the following procedure.

[0171] Mixed lipoprotein lipase (LPL, manufactured by Asahi Kasei Co., Ltd.) 75U, glycylglycine (manufactured by Wako Pure Chemical Industries, Ltd.) 5mM (0.65μg) and hexaamine chloride per 1 sensor (sample volume: 2μl) Ruthenium (III) (manufactured by Wako Pure Chemical Industries, Ltd.) was 100 mM (65 μg) to obtain a solution (solution containing LPL electron carrier). The resulting LPL solution containing the electron mediator was added dropwise in such a way as to overlap (cover) the GLDH layer formed, and dried at 30° C. for 5 minutes to obtain the second reaction layer (the LPL layer containing the electron mediator). ).

[0172] In this way, the LPL layer containing the electron carrier as the second reaction layer is formed (overlaid) on the GLDH ...

Embodiment 3

[0181] The electrodes used are the electrodes of the self-designed and manufactured 3-electrode system. In this electrode, a working electrode 2, a reference electrode 3, and a counter electrode 4 made of carbon are formed on an insulating substrate 1, and a working electrode action part 2-1 made of carbon is formed with an insulating layer 5 interposed therebetween. The reference electrode action part 3-1 made of silver chloride, and the counter electrode action part 4-1 made of carbon.

[0182] The first reaction layer (GLDH) was formed in the following steps.

[0183] PQQ-dependent glycerol dehydrogenase and 10 mM (1.3 μg) glycylglycine (Wako Pure Chemical Industries, Ltd. ), 0.05% (0.5 μg) of EmulgenPP-290 (manufactured by Kao Corporation), and 0.75% (7.5 μg) of polyethylene glycol 6000 (manufactured by Wako Pure Chemical Industries, Ltd.) as a hydrophilic polymer to obtain solution (GLDH solution). The obtained GLDH solution was added dropwise to cover the working elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com