High-efficiency production process capable of improving surface accuracy of cold-drawn seamless steel tube

A seamless steel pipe and surface precision technology, applied in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of excessive temperature increase, intense reaction, tube blank damage, etc., to ensure accuracy, safe and convenient use, and improve surface accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

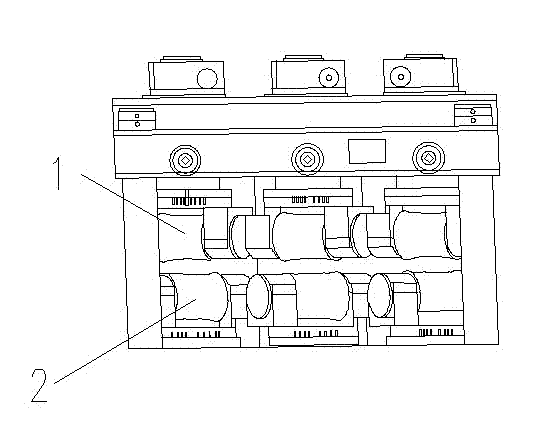

Image

Examples

Embodiment 1

[0026] In this embodiment, the steel pipe is made of German standard E355 material.

[0027] An efficient production process to improve the surface precision of cold-drawn seamless steel pipes includes the following steps:

[0028] 1) Heat treatment, the steel pipe is sent into a heat treatment furnace, heat treated at 900 degrees Celsius, and then heat preservation treatment, the heat preservation time is twice the thickness of the steel pipe wall, and the heat preservation temperature is 600 degrees Celsius. In this embodiment, the thickness of the steel pipe is 10 mm, and since the heat preservation time is twice the thickness of the steel pipe wall, the heat preservation time is 20 minutes. In the present invention, the heat preservation time in step 1) is measured in minutes, and the wall thickness of the steel pipe is measured in millimeters. Since the steel pipe will be partially oxidized by the oxygen in the air during the heat treatment process, and the higher the he...

Embodiment 2

[0042] In the efficient production process for improving the surface precision of cold-drawn seamless steel pipes in this example, step 2) process the steel pipes after mixing hydrochloric acid with a mass fraction of 5% and a release agent, and other steps are the same as in Example 1. Reducing the mass fraction of hydrochloric acid can reduce volatility, reduce pollution and improve the working environment. The hydrochloric acid and release agent with a mass fraction of 5% means that the mass of hydrochloric acid accounts for 5% of the total solution, and the amount of release agent can be added as appropriate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com