Manufacturing method for titanium and titanium alloy products by coating and forming

A manufacturing method and overmolding technology, which is applied in the field of overmolding of titanium and titanium alloy products, can solve the problems that ordinary molding methods cannot be realized, and achieve the improvement of material utilization rate and product qualification rate, material utilization rate improvement, production The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

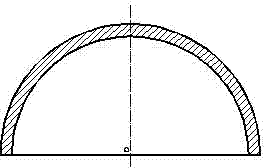

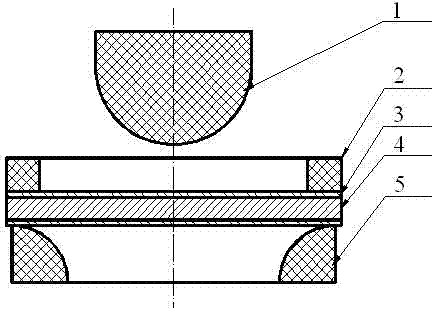

[0084] The invention has been applied to the manufacture of TC4 titanium alloy sealing head with the specification of Φ200×2mm.

[0085] (1) Cladding layer design

[0086] A. Cladding plate material: pure titanium plate.

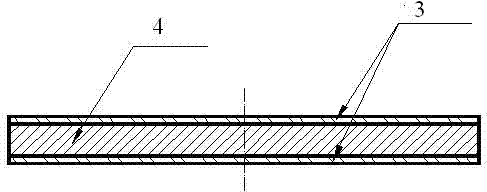

[0087] B. Thickness of cladding layer: δ=4mm.

[0088] C. Coating position and quantity: Two layers of coating are carried out on both sides of the blank in the thickness direction.

[0089] (2) Preparation before molding

[0090] A. The surface of the forming blank and cladding plate is coated with protective glass lubricant.

[0091] B. Spot weld connection of blank and cladding plate edge.

[0092] (3) Heating

[0093] A. Heating equipment: electric furnace heating.

[0094] B. Mold heating temperature: 200°C.

[0095] C. Billet heating temperature: 950°C, holding time: 10min.

[0096] (4) Forming

[0097] A. Forming fire times: 2 fire times.

[0098] B. In the process, an infrared thermometer is used to measure the surface temperature of the wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com