Method for preparing BiVO4 with photocatalytic performance under visible lights

A photocatalytic and visible light technology, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve problems such as the influence of photocatalytic performance, and achieve the effects of short reaction time, mild conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

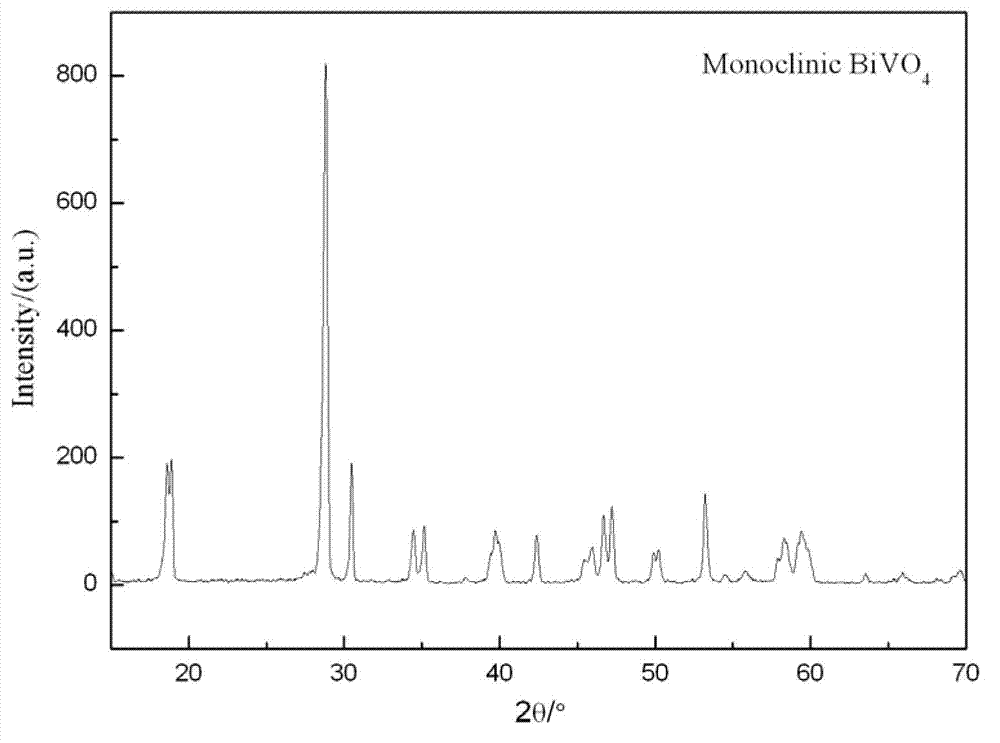

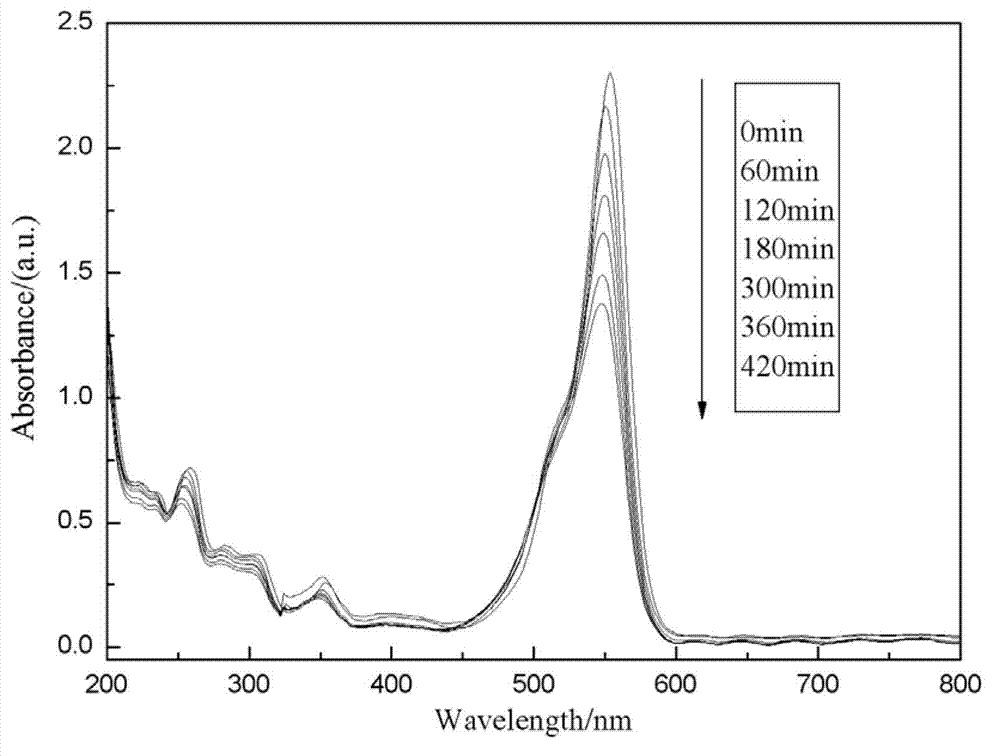

Embodiment 1

[0022] Step 1: Add 0.01mol Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water, stirred on a magnetic stirrer for 30 min at room temperature, and 0.01mol NH 4 VO 3 Dissolve in deionized water at 100°C, heat and stir on a magnetic stirrer for 30 min, and keep the heating and stirring temperature constant at 45°C.

[0023] Step 2: Mix the two solutions prepared in step 1 evenly, stir on a magnetic stirrer for 20min, then add 5ml of NaOH solution with a concentration of 1mol / L, measure the pH value to 1.33, and stir on a magnetic stirrer for 30min to obtain Precursor solution;

[0024] Step 3: Put the precursor liquid into a polytetrafluoroethylene reactor with a filling ratio of 50%, then place the reactor in a microwave-assisted hydrothermal synthesizer, set the microwave hydrothermal reaction temperature to 200°C, and the holding time to be 40min;

[0025] Step 4: After the reaction is completed, cool down, take out the yellow precipitate in the reaction kettle, wash it...

Embodiment 2

[0028] Step 1: Add 0.01mol Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water, stirred on a magnetic stirrer for 20 min at room temperature, and 0.01mol NH 4 VO 3 Dissolve in deionized water at 100°C, heat and stir on a magnetic stirrer for 20 minutes, and keep the heating and stirring temperature constant at 40°C.

[0029] Step 2: Mix the two solutions prepared in step 1 evenly, stir on a magnetic stirrer for 20min, then add 5ml of NaOH solution with a concentration of 4mol / L, measure the pH value to 2.55, stir on a magnetic stirrer for 30min, and obtain Precursor solution;

[0030] Step 3: Put the precursor solution into a polytetrafluoroethylene reactor with a filling ratio of 60%, and then place the reactor in a microwave-assisted hydrothermal synthesizer, set the microwave hydrothermal reaction temperature to 200°C, and hold the temperature for 40min;

[0031] Step 4: After the reaction is completed, cool down, take out the yellow precipitate in the reaction kettl...

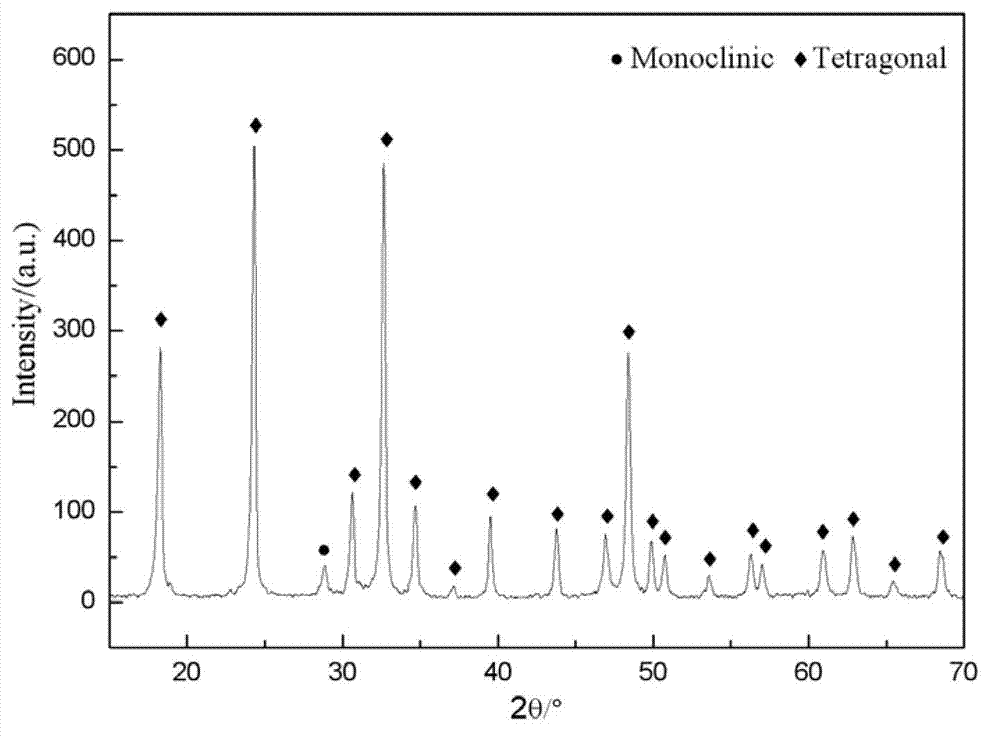

Embodiment 3

[0034] Step 1: Add 0.01mol Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water, stirred on a magnetic stirrer for 30 min at room temperature, and 0.01mol NH 4 VO 3 Dissolve in deionized water at 100°C, heat and stir on a magnetic stirrer for 35 minutes, and keep the heating and stirring temperature constant at 40°C.

[0035] Step 2: Mix the two solutions prepared in step 1 evenly, stir on a magnetic stirrer for 10 minutes, then add 5ml of NaOH solution with a concentration of 6mol / L, measure the pH value to 9.18, stir on a magnetic stirrer for 30 minutes, and obtain Precursor solution;

[0036] Step 3: Put the precursor liquid into a polytetrafluoroethylene reactor with a filling ratio of 50%, then place the reactor in a microwave-assisted hydrothermal synthesizer, set the microwave hydrothermal reaction temperature to 200°C, and the holding time to be 40min;

[0037] Step 4: After the reaction is completed, cool down, take out the yellow precipitate in the reaction ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com