Device for autotrophic nitrogen removal of composite biological membrane and operation method

An autotrophic denitrification and operating method technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to avoid large-scale fluctuations, prevent decline, and prevent sludge the loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

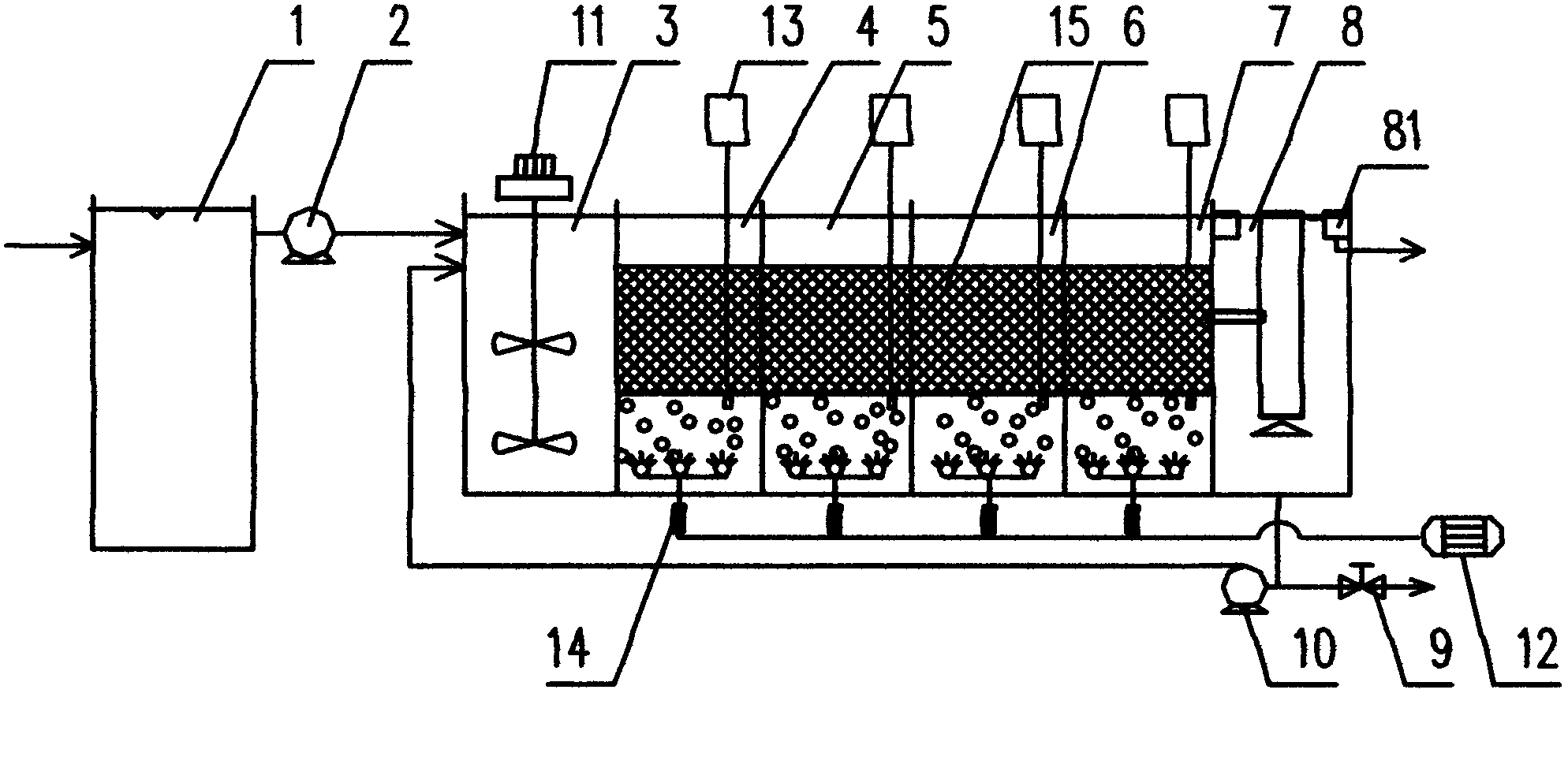

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 As shown, the composite biofilm autotrophic denitrification device is provided with an inflow tank 1, an anoxic reactor 3, and a first aerobic reactor connected in sequence to store digested sludge dehydration liquid with high ammonia nitrogen concentration. 4. The second aerobic reactor 5, the third aerobic reactor 6, the fourth aerobic reactor 7 and the sedimentation tank 8; the water inlet of the water inlet tank is communicated with the digested sludge dehydration liquid of the sewage treatment plant, The water outlet of the water inlet tank communicates with the water inlet of the anoxic reactor 3 through the water inlet pump 2; The pipeline is communicated with the anoxic reactor 3; the anoxic reactor 3 is provided with an agitator 11; the first, second, third, and fourth aerobic reactors are provided with a regular cubic shape with a side lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com