Preparation method of bio-based solubilizing and toughening agent-modified epoxy asphalt material

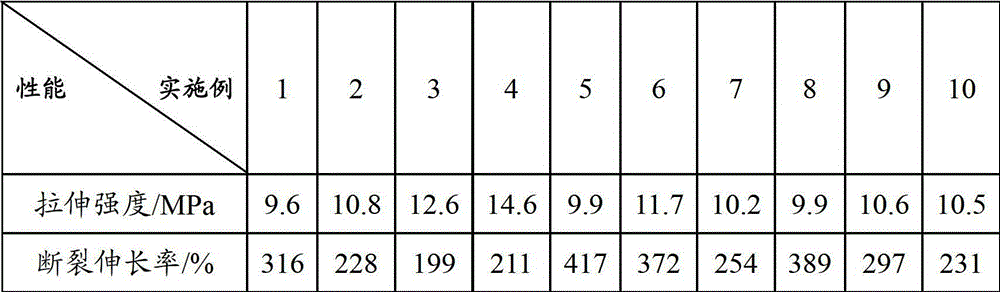

A technology of epoxy asphalt material and toughening agent, which is applied in the direction of building insulation materials, building structures, building components, etc., can solve the problems of insufficient material ductility, difficult to balance tensile strength and elongation at break, etc., to achieve Excellent strength and ductility, improved ductility, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the first step, put 200g of linseed oil, 300g of eucalyptus seed oil and 100g of glacial acetic acid into the reactor, stir and heat to 50°C, then add 300mL of 30%wt hydrogen peroxide solution and 25g of concentrated sulfuric acid (98%wt) dropwise Mixed acid catalyst with phosphoric acid (1:5, v / v), keep warm for 8 hours after the dropwise addition, let stand for a while to separate the water layer, adjust the pH value to neutral, wash with hot water 3 times, and distill under reduced pressure Prepare epoxy fatty acid ester; put 450g of epoxy fatty acid ester and 1000mL petroleum ether (90-120°C) solvent into the reactor, add 1.5g of HBF at 30°C 4 After adding the catalyst, the temperature was raised to 70°C, an inert gas protective gas was introduced into the reactor, the pressure was maintained at 10 bar, the reaction was carried out for 5 hours, and the pressure was reduced to 1 atmospheric pressure. After taking out the reaction liquid, the solvent petroleum ether...

Embodiment 2

[0033] In the first step, 400g of linseed oil, 100g of rubber seed oil and 100g of glacial acetic acid were placed in a reactor, stirred and heated to 50°C, and then 300mL of 30%wt hydrogen peroxide solution, 15g of concentrated sulfuric acid (98%wt) and Phosphoric acid mixed acid catalyst (1:5, v / v), keep warm for 6 hours after the dropwise addition, let it stand for a while to separate the water layer, adjust the pH value to neutral, wash with hot water for 3 times, and distill under reduced pressure to prepare Epoxy fatty acid ester is obtained; 450g of epoxy fatty acid ester and 1000mL benzene solvent are placed in the reactor, and 6g CF is added at 30°C 3 COOH catalyst, after the addition is completed, the temperature is raised to 50 ° C, an inert gas protection gas is introduced into the reactor, the pressure is kept at 5 bar, the reaction is 3 hours, the pressure is reduced to 1 atmosphere, the reaction liquid is taken out, and the benzene solvent is distilled off under ...

Embodiment 3

[0037] In the first step, put 250g of black meal seed oil, 250g of jatropha seed oil and 120g of glacial acetic acid into the reactor, stir and heat to 75°C, then add 400mL of 30%wt hydrogen peroxide solution and 25g of concentrated sulfuric acid (98%wt) dropwise. ) and phosphoric acid mixed acid catalyst (1:5, v / v), keep warm for 8 hours after the dropwise addition, let stand for a while to separate the water layer, adjust the pH value to neutral, wash with hot water 3 times, and distill under reduced pressure Finally, the epoxy fatty acid ester was prepared; the prepared 450g epoxy fatty acid ester and 1000mL carbon tetrachloride solvent were placed in the reactor, and 5gAlCl was added at 30°C 3 Catalyst, be warming up to 70 ℃ after adding, in the reactor, introduce inert gas protective gas, keep pressure 10bar, react 5h, depressurize to 1 atmospheric pressure, remove carbon tetrachloride solvent under reduced pressure again after taking out reaction liquid, preparation poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com