Method for utilizing zeolite in-situ adsorption to separate and purify butanol, acetone and ethanol in fermenting solution online

A fermentation liquid and ethanol technology, applied in the biological field, to achieve the effects of low fermentation efficiency, improved fermentation efficiency, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for on-line separation and purification of butanol, acetone and ethanol in fermentation broth by using zeolite in-situ adsorption;

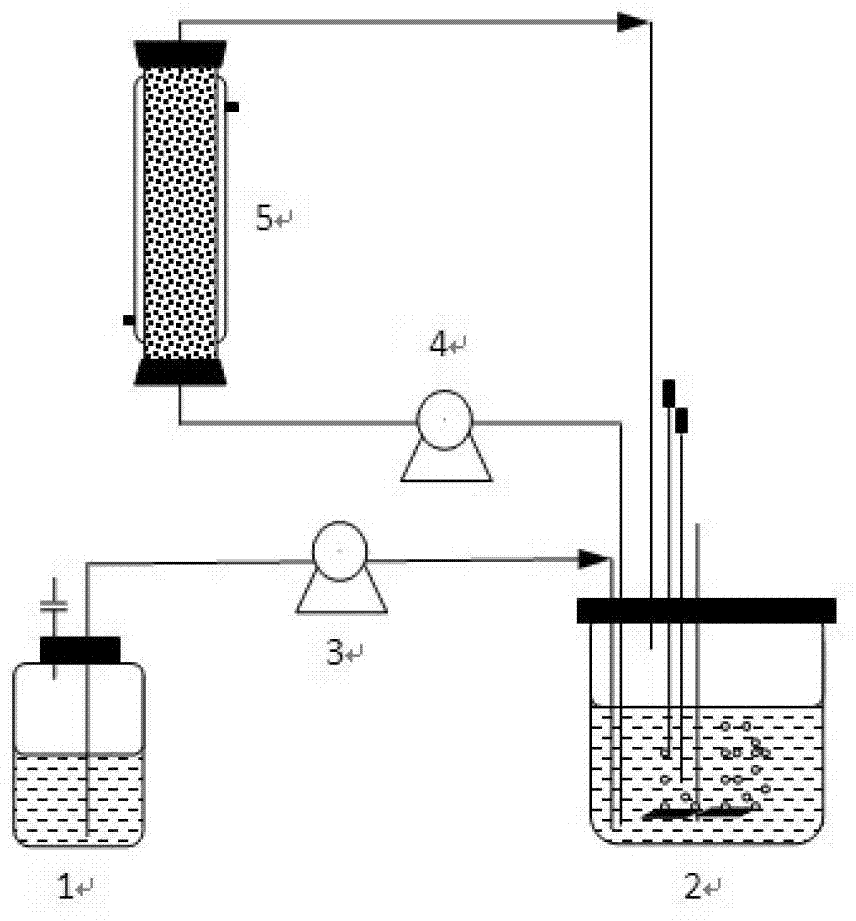

[0047] ① if figure 1 As shown, the seed medium was first passed nitrogen in the seed tank for 10 minutes to deoxygenate, then sterilized at 121°C for 30 minutes, cooled to room temperature, inserted into the acetone butanol ethanol production bacteria, and the production bacteria were cultivated to the most active logarithm of growth growth period. The cultivation time until the logarithmic growth phase is 12-18 hours, preferably 15 hours; the cultivation temperature is 30-40°C, preferably 37°C. After the seed culture is completed, it is ready to be inserted into the fermenter.

[0048] ② if figure 1 As shown, first sterilize the fermentation medium at 121°C for 30 minutes, then pass nitrogen gas for 2 hours to deoxygenate, cool to room temperature, turn on the pump I, and put the seed liquid containing acetone, butanol and e...

Embodiment 2

[0053] A method for on-line separation and purification of butanol, acetone and ethanol in fermentation broth by using zeolite in-situ adsorption;

[0054] The difference with embodiment 1 is:

[0055] The mass ratio of zeolite molecular sieve CBV28014 to fermentation broth is 1:10.

[0056] The experimental data are shown in Table 1 and Table 2.

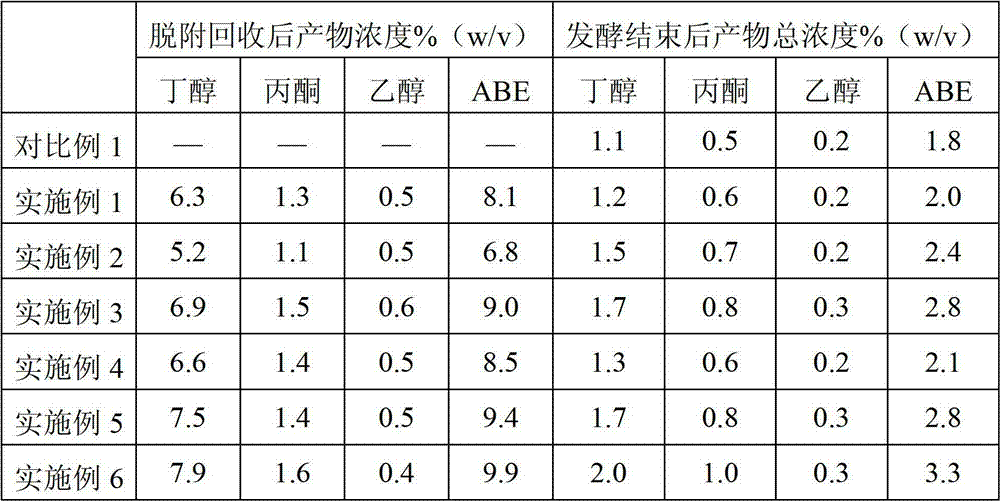

[0057] Summary: After the fermentation, the concentrations of butanol and ABE total solvent were 1.5% (w / v) and 2.4% (w / v), respectively, which were 36.4% and 33.3% higher than those in Comparative Example 1. Glucose consumption was 7.4% (w / v), an increase of 34.5% compared with Comparative Example 1. The concentrations of butanol and ABE total solvent recovered after desorption were 5.2% (w / v) and 6.8% (w / v), respectively, which were 4.7 times and 3.8 times higher than those of Comparative Example 1. The production intensity of butanol and ABE total solvents are 0.25g / L / h and 0.42g / L / h, which are 13.6% and 16.7% higher than that...

Embodiment 3

[0059] A method for on-line separation and purification of butanol, acetone and ethanol in fermentation broth by using zeolite in-situ adsorption;

[0060] The difference with embodiment 1 is:

[0061] The mass ratio of zeolite molecular sieve CBV28014 to fermentation broth is 1:5.

[0062] The experimental data are shown in Table 1 and Table 2.

[0063] Summary: After the fermentation, the concentrations of butanol and ABE total solvent were 1.7% (w / v) and 2.8% (w / v), respectively, which were 54.5% and 55.6% higher than those in Comparative Example 1. Glucose consumption was 8.5% (w / v), an increase of 54.5% compared with Comparative Example 1. The concentrations of butanol and ABE total solvent recovered after desorption were 6.9% (w / v) and 9.0% (w / v), which were 6.3 times and 5.0 times higher than those of Comparative Example 1, respectively. The production intensity of butanol and ABE total solvents are 0.27g / L / h and 0.46g / L / h, which are increased by 22.7% and 27.8% comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com