Super eight-stroke huge-power high-energy-saving ultralow-emission engine master device

An eight-stroke, huge-power technology, applied in the field of super eight-stroke, huge-power, high-energy-saving and ultra-low-emission engine main parts, can solve the problems of rare eight-stroke engines, and achieve the effects of low cost, convenient manufacture, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

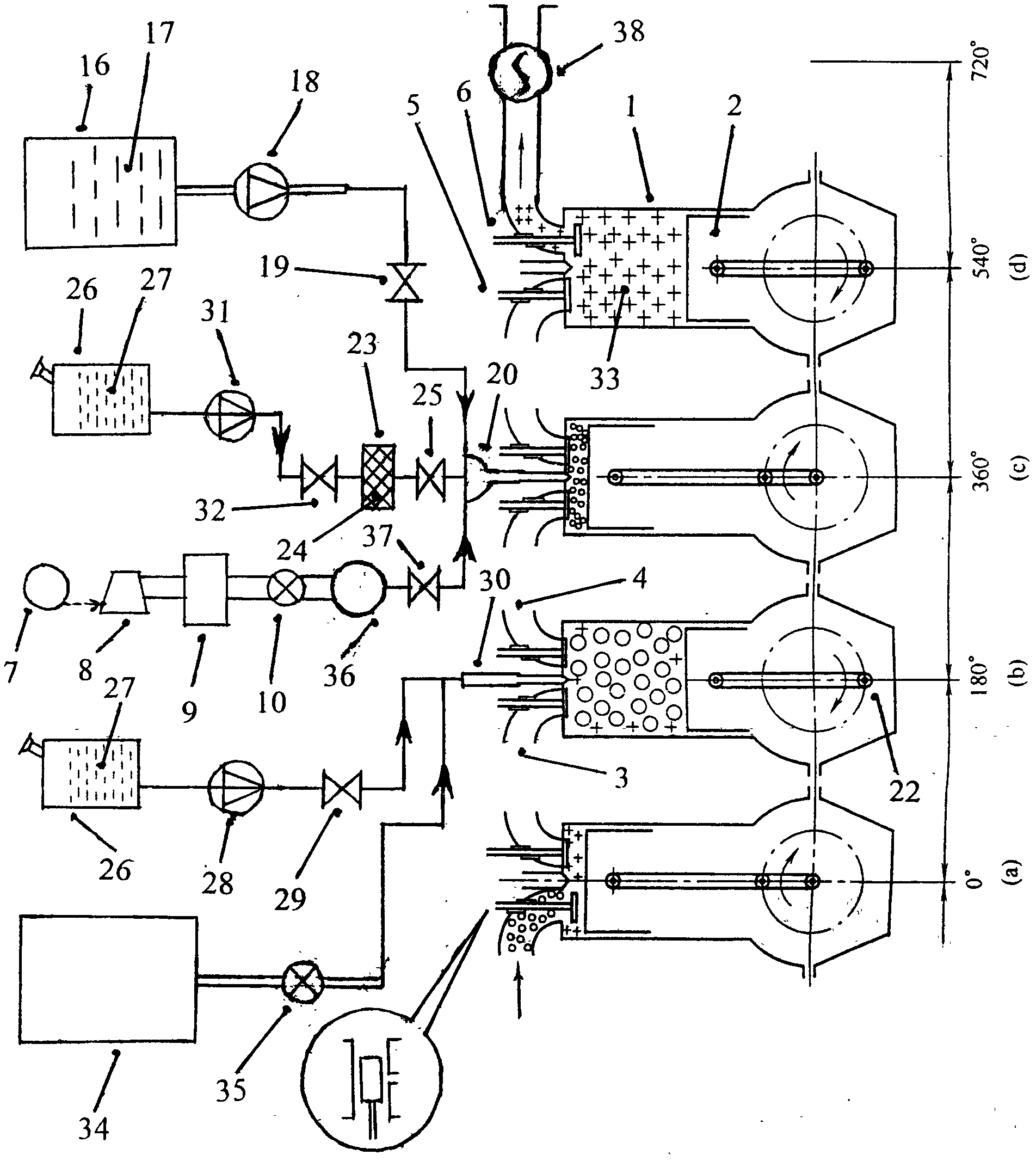

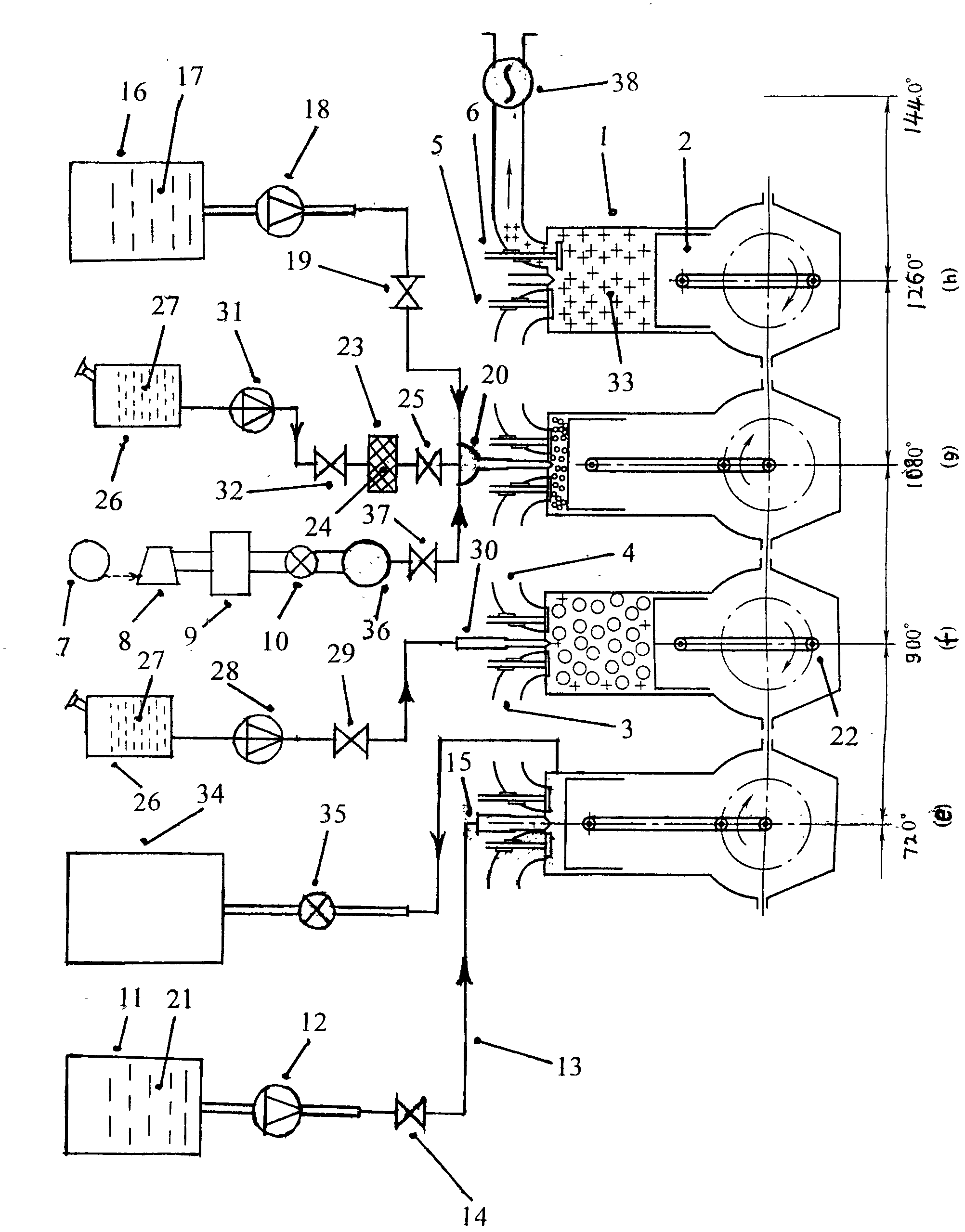

[0011] exist figure 1 Among them, the piston (2) is set on the high-pressure cylinder (1), the shutter intake valve (5) and the shutter exhaust valve (6) are connected to the upper part of the high-pressure cylinder (1), and the high-pressure cylinder (1) is set The high-temperature ultra-high expansion ratio ultra-high-speed combustion chamber (33) is provided with a connection shutter intake valve (5) on the air intake passage (3), and a connection shutter exhaust valve (6) is provided on the exhaust passage (4). On the injector (30), the high-energy fuel tank (26), the medium-pressure fuel pump (28), the high-temperature oxygen-enriched combustion input control system (29) and the injector (30) connected with the high-energy fuel A high-energy fuel (27) is arranged in the tank (26), and one end of the medium-pressure fuel pump (28) is connected to the high-energy fuel tank (26) and the other end is connected to the high-temperature oxygen-enriched combustion input control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com