Infrared low-temperature combustion device and method for dual-mass combined cycle turbine

A combined cycle, low-temperature combustion technology, applied in combustion methods, combustion chambers, combustion equipment, etc., to achieve the effects of low manufacturing cost, elimination of thermal damage, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

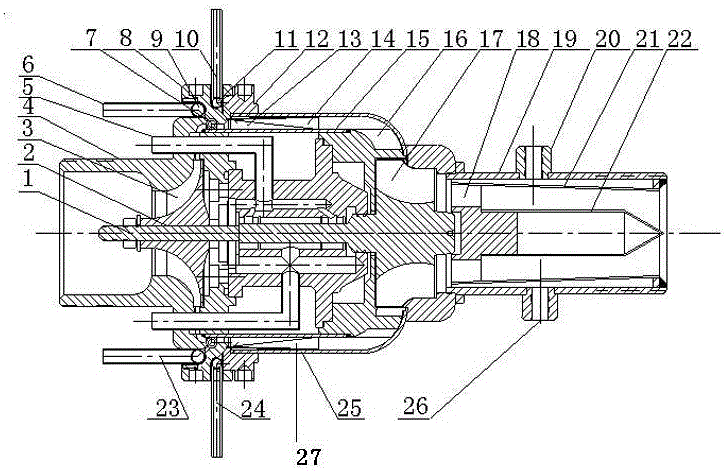

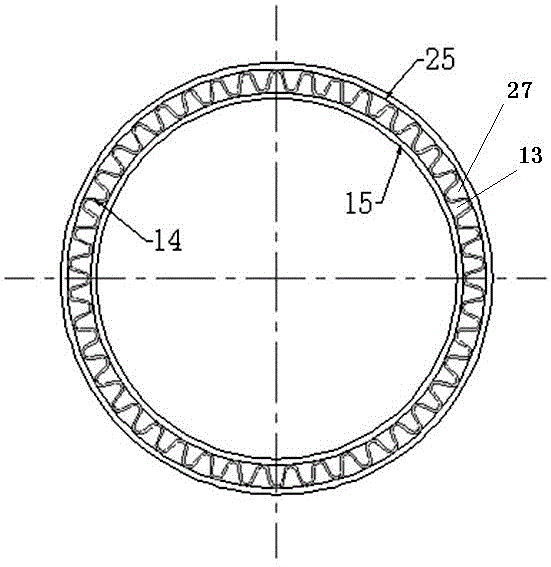

[0018] see figure 1 , 2 , the names of parts are as follows: Turbine and shaft 1, compressor impeller 2, compressor blade 3, compressor housing 4, lubricating oil inlet 5, fuel inlet 6, infrared grill 7, oil and water nozzle middle body 8, spray Oil nozzle 9, exhaust port 10, water nozzle 11, water nozzle gland 12, annular combustion chamber 13, longitudinal corrugated isolation plate 14, combustion inner wall 15, swirl guide plate 16, turbine blade 17, stator guide plate 18, Invisible heat exchanger 19, warm water outlet 20, exhaust pipe 21, slow decay filling core 22, fuel oil backup inlet 23, second working medium inlet 24, phase change outer wall 25, cold water inlet 26, phase change chamber 27.

[0019] The dual working medium combined cycle turbine includes a moving part, a fuel supply system, a second working medium supply system, an electrical system, a lubrication system, and a load. The specific experimental structure is: it includes a turbine and shaft 1, a right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com