Interference lithography system and method based on spatial light modulator

A technology of spatial light modulator and interference lithography, which is applied in the field of interference lithography system based on spatial light modulator, can solve the problems of complex system, low efficiency and no simplicity, and achieve the effect of high-efficiency lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

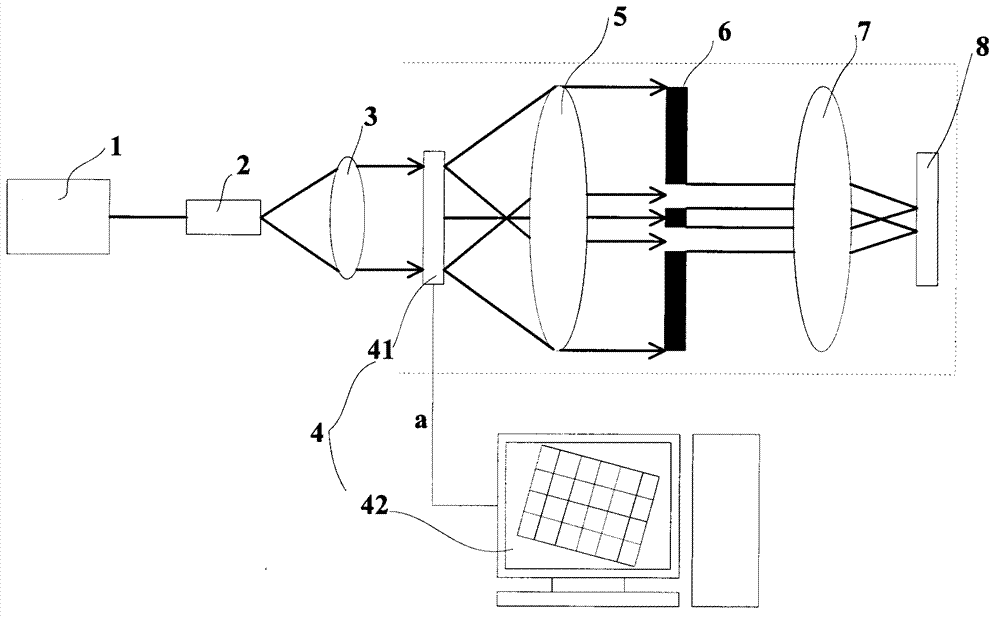

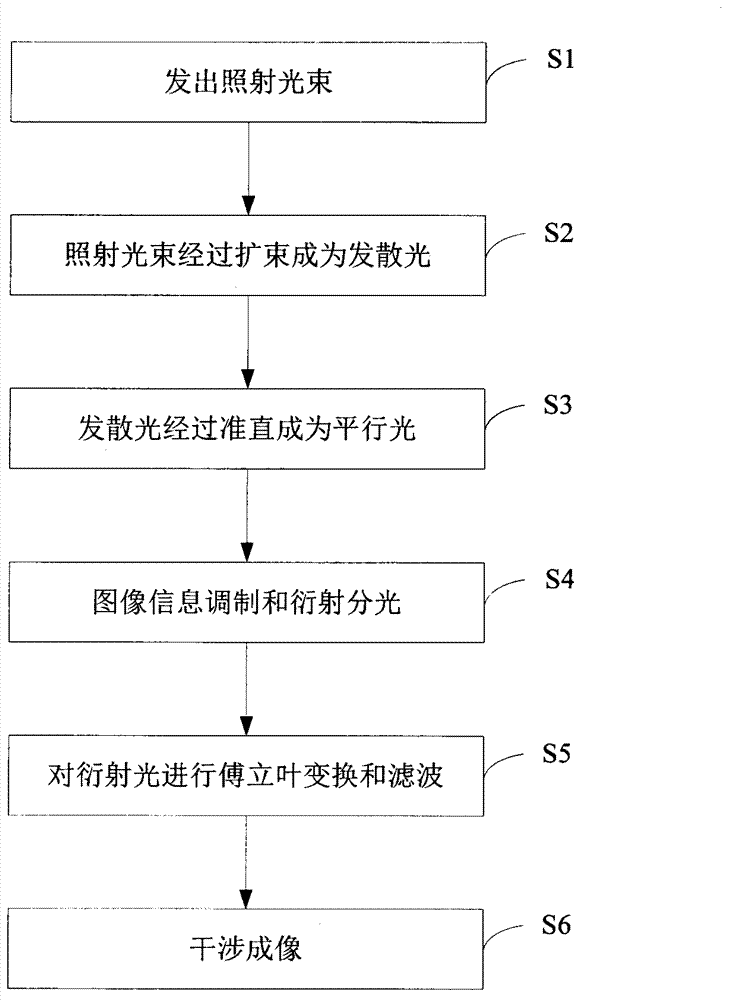

[0043] This embodiment provides an interference lithography system and method based on a spatial light modulator. see figure 1As shown, it is a schematic structural diagram of an interference lithography system based on a spatial light modulator in Embodiment 1 of the present invention. The system includes in order according to the direction of beam propagation: a light source, a beam expander 2, a collimator lens 3, a spatial light modulation device 4, and a Fourier Transformation lens 5, Fourier transform spectrum filter baffle 6, imaging mirror, photoresist dry plate, wherein the photoresist dry plate is a glass dry plate coated with photoresist. Interference lithography needs to use a light source with strong coherence. In this embodiment, in order to achieve higher definition, the light source is laser 1, and the irradiation beam emitted by laser 1 is laser. The spatial light modulation device 4 includes a spatial light modulator and a computer 42. The spatial light modu...

Embodiment 2

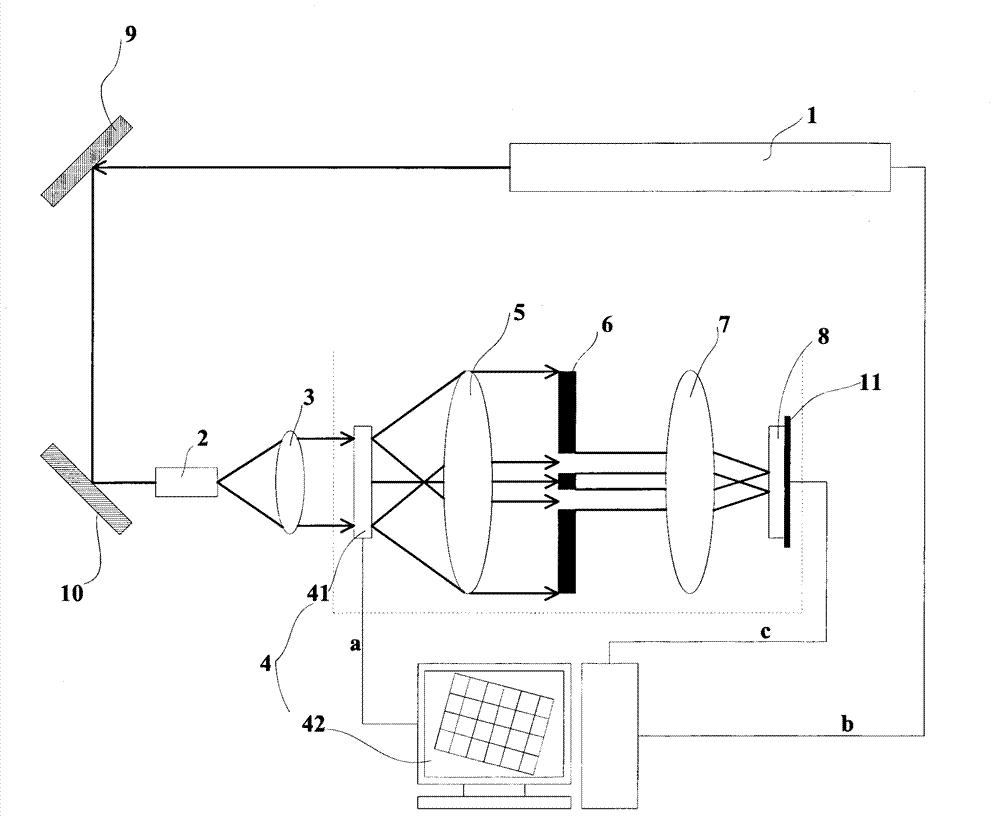

[0065] The difference between this embodiment and Embodiment 1 is that when the optical path of the laser is not in the same direction as other optical elements such as the beam expander, it is necessary to add a plane reflector so that the beam can be incident on the beam expander; this embodiment also adds a light Resist dry plate mobile unit for high resolution pattern exposure. Only the different parts of this embodiment and the first embodiment will be described below, and the same parts will not be described again.

[0066] see image 3 As shown, it is a schematic structural diagram of an interference lithography system based on a spatial light modulator in Embodiment 2 of the present invention. In this embodiment, on the basis of Embodiment 1, a first plane mirror 9, a second plane mirror 10, and a photoresist dry plate moving device are added. In this embodiment, the photoresist dry plate is a holographic dry plate 8, Therefore, the photoresist dry plate moving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com