System and method for controlling automatic production line

An automated production line and control system technology, applied in the direction of total factory control, total factory control, electrical program control, etc., to achieve the effects of reducing production costs, improving production efficiency, and improving balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

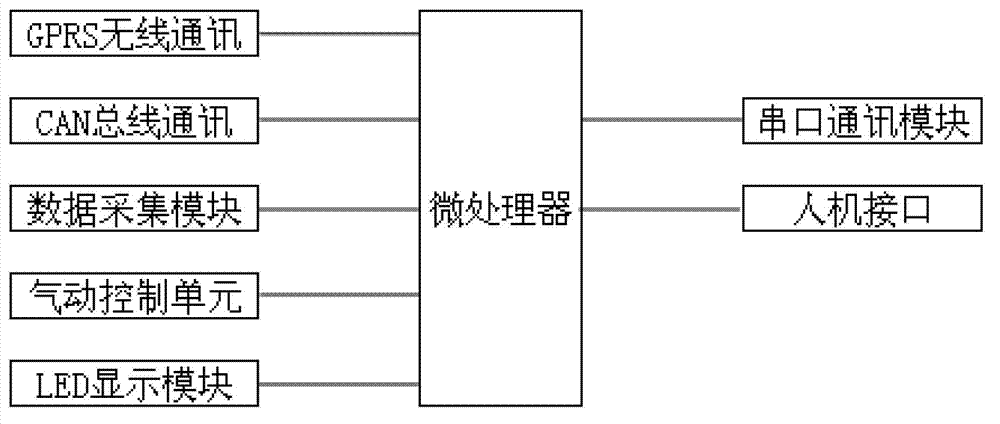

[0059] For a long time, automation control technology has been an important driving force for technological innovation and industrial upgrading in production, processing, assembly and other links. Traditional control technology uses various sensors to obtain information. However, with the development of RFID radio frequency identification technology, the use of RFID for non-contact automatic identification technology has become very mature. The perfect combination of RFID technology and control technology is applied to the control and Optimization becomes a reality.

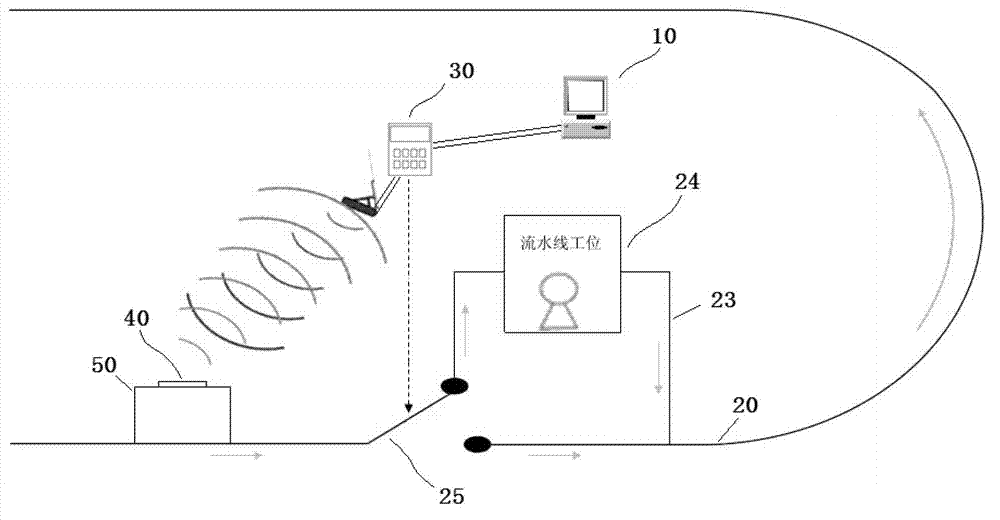

[0060] see figure 1 , figure 2 , the present invention discloses an automatic production line control system, the system includes: an assembly line, several intelligent terminals 30, and a management server 10.

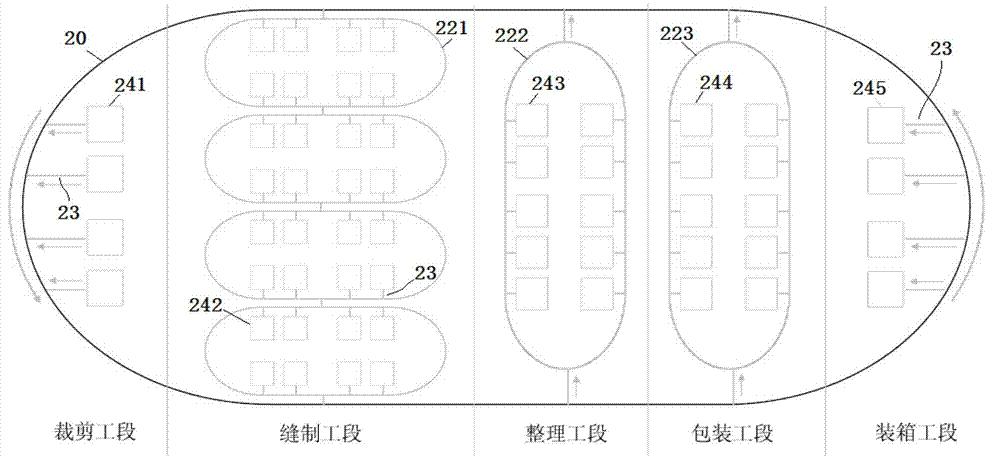

[0061] from figure 1 It can be seen that the entire garment production and processing process, including sewing, finishing or ironing, packaging, packing (boxing) and other links, is under the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com