Heavy metal polluted soil remediation device and method

A technology of polluted soil and remediation method, which is applied to a device for remediating heavy metal-contaminated soil by bioleaching and plant adsorption, and in the field of remediation of heavy metal-contaminated soil, which can solve environmental pollution and other problems, achieve convenient use, reduce remediation costs, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

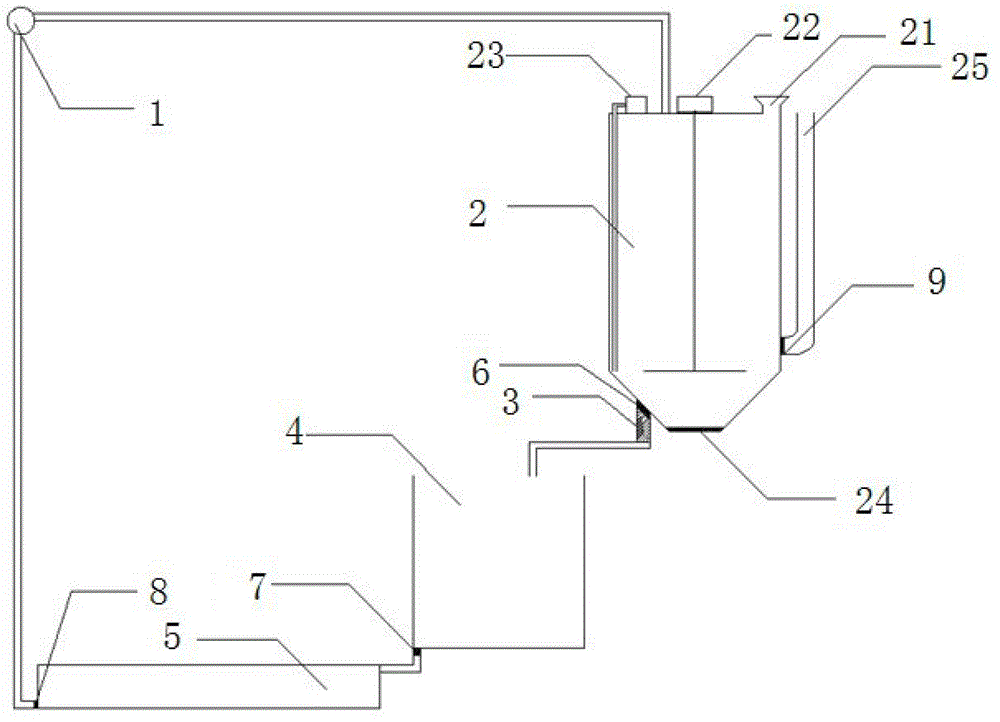

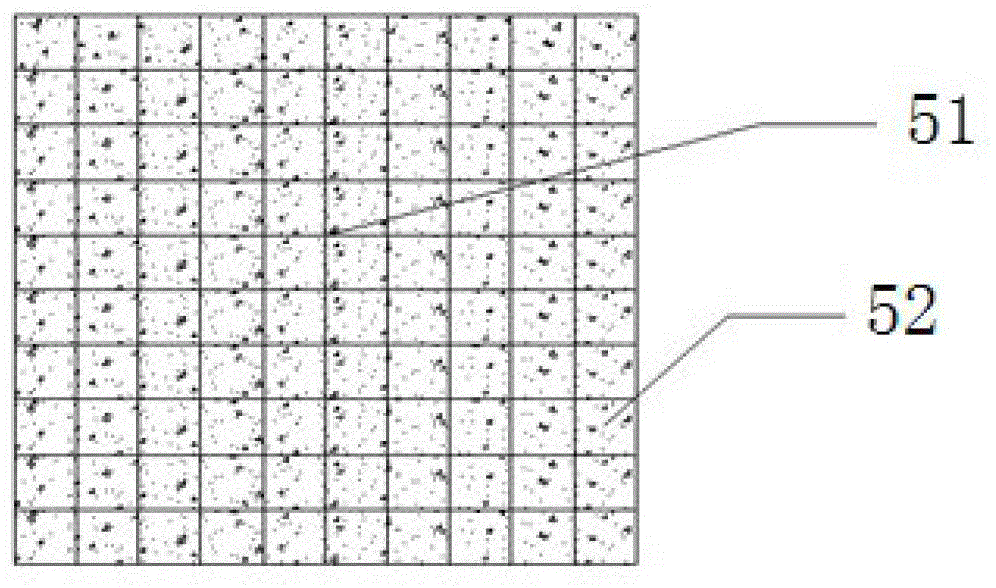

[0025] Heavy metal contaminated soil remediation device, see Figure 1 to Figure 2 , including a peristaltic pump 1 , a bioleaching reactor 2 , a microporous filter column 3 , a regulating tank 4 and a plant treatment tank 5 which are sequentially connected in a loop through communication pipes.

[0026] The top of the bioleaching reactor 2 is provided with a sample inlet 21, an agitator 22 inside, an aeration device 23 on the outer wall, and a sample outlet 24 at the bottom, and the gas outlet of the aeration device 23 is located in the bioleaching reactor 2; a first control valve 6 is provided between the bioleaching reactor 2 and the microporous filter column 3, a second control valve 7 is provided between the regulating tank 4 and the plant treatment tank 5, and the bottom of the plant treatment tank 5 is provided with The third control valve 8.

[0027] In the present invention, a columnar connector 25 is also provided, one end of which communicates with the bottom of th...

Embodiment 2

[0030] Utilize the heavy metal contaminated soil remediation device of embodiment 1 to once process heavy metal contaminated soil, the method is as follows:

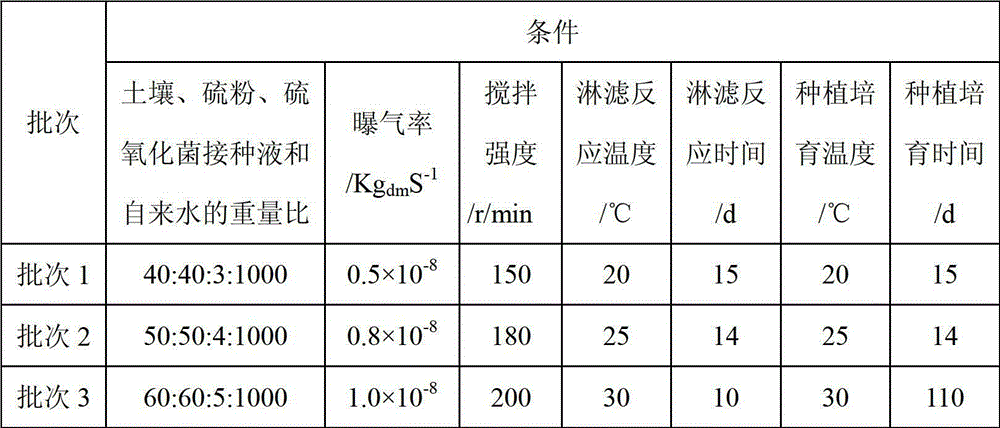

[0031] (1) Add the soil to be treated, sulfur powder, sulfur oxidizing bacteria inoculum and water into the bioleaching reactor 2, stir and aerate, and perform leaching reaction to obtain a reaction mixture; the reaction conditions are as follows: the soil, sulfur The weight ratio of powder, sulfur oxidizing bacteria inoculum and tap water is (40-60): (40-60): (3-5): 1000; the aeration rate is 0.5×10 -8 -1.0×10 -8 QUR -1 , the stirring intensity is 150-200r / min, the leaching reaction temperature is 20-30°C, and the leaching reaction time is 10-15 days.

[0032] (2) Filter the reaction mixture through the microporous filter column 3 and discharge it into the regulating tank 4, add water to the original water volume, and adjust the pH to 5-7 to obtain a leachate; use the sample outlet 24 to discharge the soil;

[0033] ...

Embodiment 3

[0040] Utilize the heavy metal-contaminated soil remediation device of embodiment 1 to recycle the heavy-metal-contaminated soil, the method is as follows:

[0041] (a) Close all control valves, inject water from the inlet 21 to the height of 2 to 3 / 4 of the bioleaching reactor. Add soil to be treated, sulfur powder, sulfur oxidizing bacteria inoculum; wherein, the weight ratio of soil, sulfur powder, sulfur oxidizing bacteria inoculum and tap water is 50:50:4:1000, open agitator 22 and aeration device 23, Aeration rate 0.5×10 -8 QUR -1 , the stirring intensity is 150r / min, the treatment temperature is 25°C, and the treatment time is 14 days.

[0042](b) Open the fourth control valve 9, and close the fourth control valve 9 after the reaction mixture enters the cylindrical connector 25; open the first control valve 6, and the reaction mixture enters the regulating tank 4 through the microporous filter column 3, Close the first control valve 6; close the agitator 22 and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com