Antiflaming waste rubber powder modified asphalt wet-paving waterproof coiled material and production method thereof

A technology for modifying asphalt and waterproofing membranes, which is applied in the directions of asphalt layered products, asphalt material adhesives, chemical instruments and methods, etc. Building hidden dangers and other problems, to achieve the effect of outstanding elasticity, long-lasting bonding, and large bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

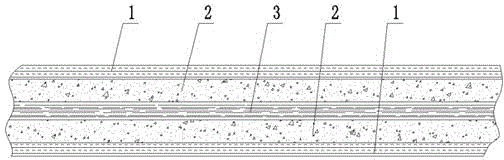

[0039] Production of flame-retardant waste rubber powder modified asphalt wet paving waterproofing membrane, the main material layer (3) is glass fiber cloth, the two sides of the main material layer (3) are capable of chemical cross-linking reaction and physical tenon synergy with concrete The modified asphalt adhesive layer (2) for bonding, and the isolation protection layer (1) is a polyethylene film or a polyvinyl chloride film;

[0040] Among them, the modified asphalt bonding layer that can have chemical cross-linking reaction and physical mortise and tenon synergistic bonding with concrete is to add asphalt to waste rubber powder, tackifier, functional additives, random polyethylene and styrene- The butadiene-styrene block copolymer is modified, and the tackifier is obtained by refining styrene-butadiene rubber at a high temperature of 180-230°C. The weight percentage of the tackifier accounts for the total amount of modified asphalt. 5-7% of the weight; the weight perc...

Embodiment 2

[0042] Production of flame-retardant waste rubber powder modified asphalt wet paving waterproofing membrane, the main material layer (3) is glass fiber cloth, the two sides of the main material layer (3) are capable of chemical cross-linking reaction and physical tenon synergy with concrete The modified asphalt adhesive layer (2) for bonding, and the isolation protection layer (1) is a polyester film;

[0043] Among them, the modified asphalt bonding layer that can have chemical cross-linking reaction and physical mortise and tenon synergistic bonding with concrete is to add asphalt to waste rubber powder, tackifier, functional additives, random polyethylene and styrene- The butadiene-styrene block copolymer is modified, and the tackifier is obtained by refining styrene-butadiene rubber at a high temperature of 180-230°C. The weight percentage of the tackifier accounts for the total amount of modified asphalt. 6-8% by weight; the weight percentage of random polypropylene accou...

Embodiment 3

[0045] Production of flame-retardant waste rubber powder modified asphalt wet paving waterproofing membrane, the main material layer (3) is glass fiber cloth, the two sides of the main material layer (3) are capable of chemical cross-linking reaction and physical tenon synergy with concrete The modified asphalt bonding layer (2) for bonding, and the isolation protection layer (1) is a polyethylene film or a polyester film;

[0046] Among them, the modified asphalt bonding layer that can have chemical cross-linking reaction and physical mortise and tenon synergistic bonding with concrete is to add asphalt to waste rubber powder, tackifier, functional additives, random polyethylene and styrene- The butadiene-styrene block copolymer is modified, and the tackifier is obtained by refining styrene-butadiene rubber at a high temperature of 180-230°C. The weight percentage of the tackifier accounts for the total amount of modified asphalt. 8-10% of the weight; the weight percentage of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com