Supported PtAu catalyst and method for catalytic reduction of olefinic bonds or acetylenic bonds by using same

A supported catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic reduction, etc., can solve problems such as poor stability, difficulty in preparation, large amount of catalyst or additives, etc., to achieve mild reaction conditions and preparation The effect of simple procedure, selectivity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

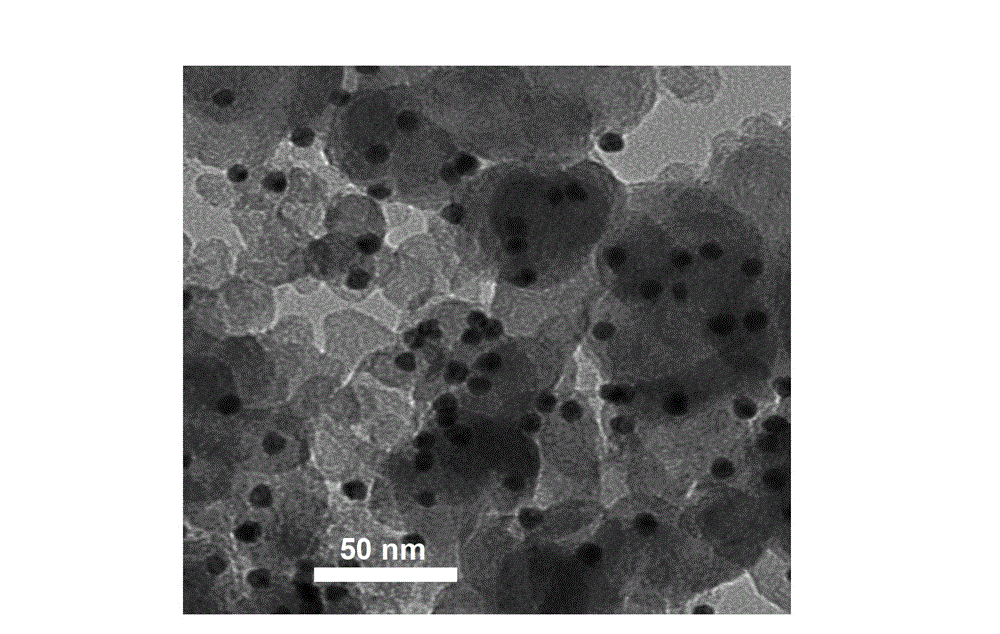

[0045] Implementation method: heat octadecylamine to form a clear solution as solvent, surfactant and reducing agent. Continue heating to 140 DEG C, then add platinum acetylacetonate and chloroauric acid tetrahydrate, wherein the concentration of platinum acetylacetonate and chloroauric acid tetrahydrate is 0.0022mol / L. Continue heating to 230°C, stir for 20 minutes, then cool to room temperature, wash with ethanol to obtain bimetallic PtAu, and disperse it in cyclohexane. Then add activated carbon, wherein the mass ratio of bimetallic PtAu to activated carbon is 1:20, the mixture is stirred at room temperature for 12h and then filtered, and then the filter residue is washed with cyclohexane and dried to obtain supported PtAu, wherein the PtAu nanoparticles The grain size is 9nm.

Embodiment 3

[0047] Implementation method: heat octadecylamine to form a clear solution as solvent, surfactant and reducing agent. Continue heating to 150° C., then add platinum acetylacetonate and chloroauric acid tetrahydrate, wherein the concentrations of platinum acetylacetonate and chloroauric acid tetrahydrate are 0.0044mol / L. Continue heating to 250°C, stir for 30 minutes, then cool to room temperature, wash with ethanol to obtain bimetallic PtAu, and disperse it in cyclohexane. Activated carbon was added, wherein the mass ratio of bimetallic PtAu to activated carbon was 1:40, the mixture was stirred at room temperature for 24 h and then filtered, and the filter residue was washed with cyclohexane and dried to obtain supported PtAu, in which the crystals of PtAu nanoparticles The particle size is 15nm.

Embodiment 4

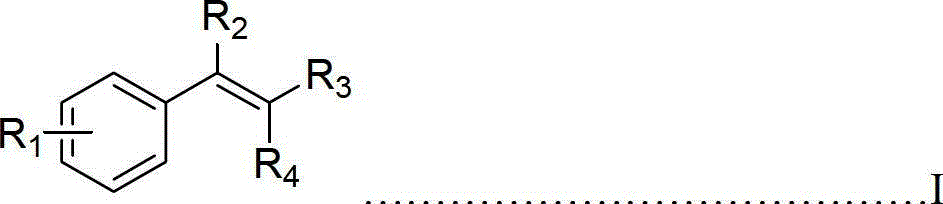

[0049]

[0050] Implementation method: at normal temperature, place 2-bromostyrene and supported PtAu in methanol, wherein the molar concentration of the substrate is 0.10 mol / L, and the molar concentration of the catalyst is 0.0012 mol / L. After the reactor was sealed, a balloon filled with hydrogen was added, and the gas was changed continuously for 3 times. Under stirring, the mixture was reacted at room temperature for 4 hours, and the catalyst was recovered by filtration. The filtrate was analyzed by gas chromatography-mass spectrometry, and the yield was 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com