Nano antibacterial polypropylene pipe and preparation method of same

An antibacterial polypropylene, polypropylene technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problem of harmful substances such as bacteria that cannot kill water, and achieve easy hot-melt connection, strong corrosion resistance, and huge social The effect of benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

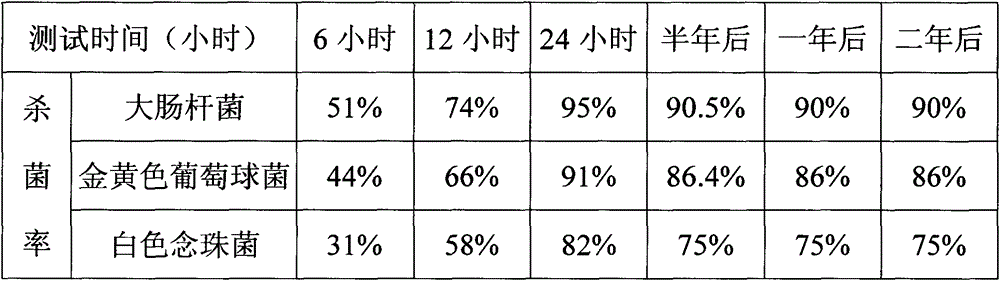

Image

Examples

Embodiment Construction

[0018] A nano antibacterial polypropylene pipe mainly consists of polypropylene, an inorganic antibacterial agent and a processing aid, and the percentage by weight of each component of the pipe is:

[0019] Polypropylene resin: 93% to 99%;

[0020] Inorganic nano antibacterial agent: 0.2~3%;

[0021] Antioxidants and anti-ultraviolet absorbers: 0.8 to 4%.

[0022] Concrete preparation process is as follows:

[0023] (1) Preparation of masterbatch:

[0024] First, add 1.0% coupling agent NDZ-1 and 0.5% low molecular weight polyethylene wax into the inorganic nano antibacterial agent according to the percentage of the total weight of the inorganic nano antibacterial agent; Stir 60 times per minute for 1.5-2 minutes for impregnation; dry the mixed powder after impregnation at 90-120°C for 90-100 minutes;

[0025] According to the total weight percentage of inorganic nano antibacterial powder, 19% antibacterial active powder and 1% polyethylene wax and 80% polypropylene resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com