Technology for producing natural gas through underground coal gasification

A coal gasification and natural gas technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of complex process, large investment, complex composition, etc., and achieve the effect of rich raw material sources, increased economic benefits, and low equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

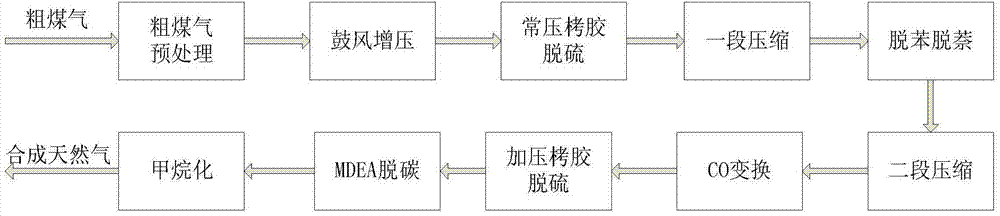

Method used

Image

Examples

Embodiment 1

[0025] The crude gas produced by underground coal gasification (hereinafter referred to as crude gas) is composed of: H 2 : 34.5%mol; CH 4 : 2.5%mol; N 2 : 0.9%mol; CO: 22.64%mol; CO 2 : 20.20%mol; C n h m : 0.85%mol; O 2 : 0.28%mol, NH 3 : 0.06%, sulfide: 0.07%mol, H 2 O: 18.00% mol. Temperature: 300°C, Pressure: 0.02MPaG;

[0026] The crude gas is firstly pretreated, and the temperature of the crude gas is lowered to below 200°C after heat exchange in a low-pressure waste boiler, and part of the waste heat can be recovered. After cooling down, the crude gas enters the scrubber to absorb the phenolic ammonia in the crude gas. At the same time, more than 90% wt of tar and dust are also washed, and the washed crude gas passes through a 2-stage electric tar collector to reduce the tar content in the crude gas to 10mg / Nm 3 Below, to meet the requirements of subsequent devices. Except for a small amount of fresh water, the washing water used in the washing tower comes fr...

Embodiment 2

[0035] The crude gas produced by underground coal gasification is composed of: H 2 : 30.50%mol; CH 4 : 3.51%mol; N 2 : 0.7%mol; CO: 25.26%mol; CO 2 : 20.42%mol; C n h m : 1.20%mol; O 2 : 0.28%mol, NH 3 : 0.06%, sulfide: 0.07%mol, H 2 O: 18.00% mol. Temperature: 220°C, Pressure: 0.02MPaG;

[0036] The crude gas is first pretreated, and the temperature of the crude gas is reduced to below 200°C after passing through the low-pressure waste boiler, and part of the waste heat can be recovered. The cooled crude gas enters the washing tower again, the purpose is to absorb the phenolic ammonia in the crude gas, and at the same time, more than 90%wt of tar and dust are washed down, and the washed crude gas passes through the 2-stage electric tar catcher , reduce the tar in the crude gas to 5mg / Nm 3 Below, to meet the requirements of subsequent devices. Except for a small amount of fresh water, the washing water used in the washing tower comes from the process condensate prod...

Embodiment 3

[0045] The crude gas produced by underground coal gasification is composed of: H 2 : 36.21%mol; CH 4 : 3.51%mol; N 2 : 0.5%mol; CO: 20.26%mol; CO 2 : 20.42%mol; C n h m : 0.69%mol; O 2 : 0.28%mol, NH 3 : 0.06%, sulfide: 0.07%mol, H 2 O: 18.00% mol. Temperature: 220°C, Pressure: 0.02MPaG;

[0046] The crude gas is first pretreated, and the temperature of the crude gas is reduced to below 200°C after passing through the low-pressure waste boiler, and part of the waste heat can be recovered. The cooled crude gas enters the washing tower again, the purpose is to absorb the phenolic ammonia in the crude gas, and at the same time, more than 90%wt of tar and dust are washed down, and the washed crude gas passes through the 2-stage electric tar catcher , reduce the tar in the crude gas to 8mg / Nm 3 Below, to meet the requirements of subsequent devices. Except for a small amount of fresh water, the washing water used in the washing tower comes from the process condensate prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com