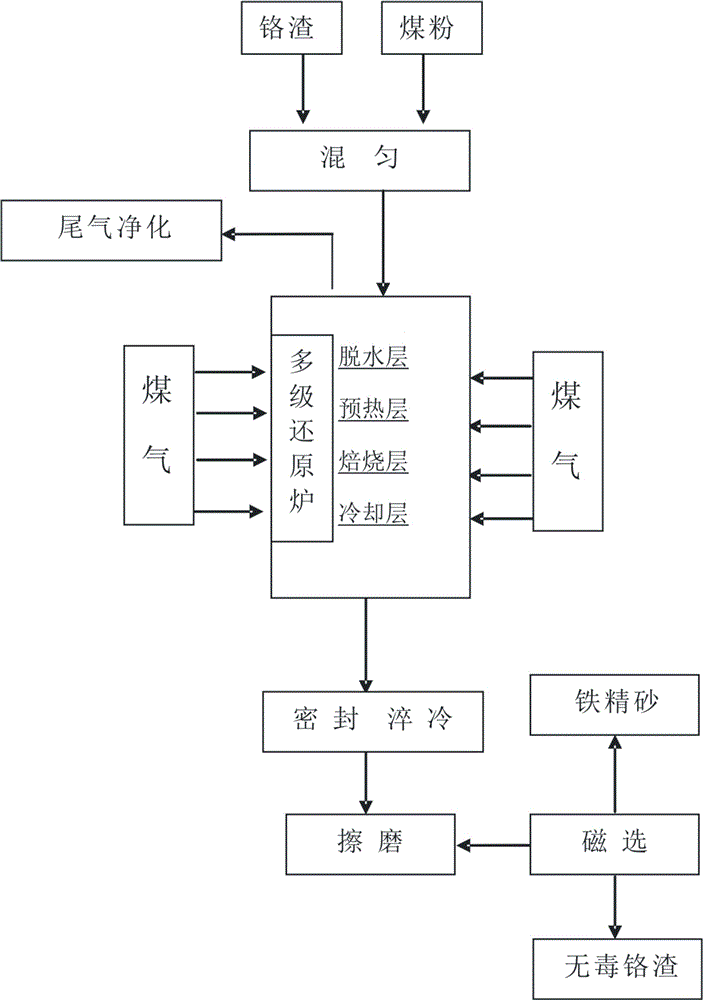

Process for reduction detoxication of chromic slag by adopting dry method

A chromium slag and dry process technology, which is applied in the field of chromium slag dry reduction and detoxification technology, can solve the problems of high production energy consumption and high cost, and achieve the effects of stable properties, low cost and no harmful secondary emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

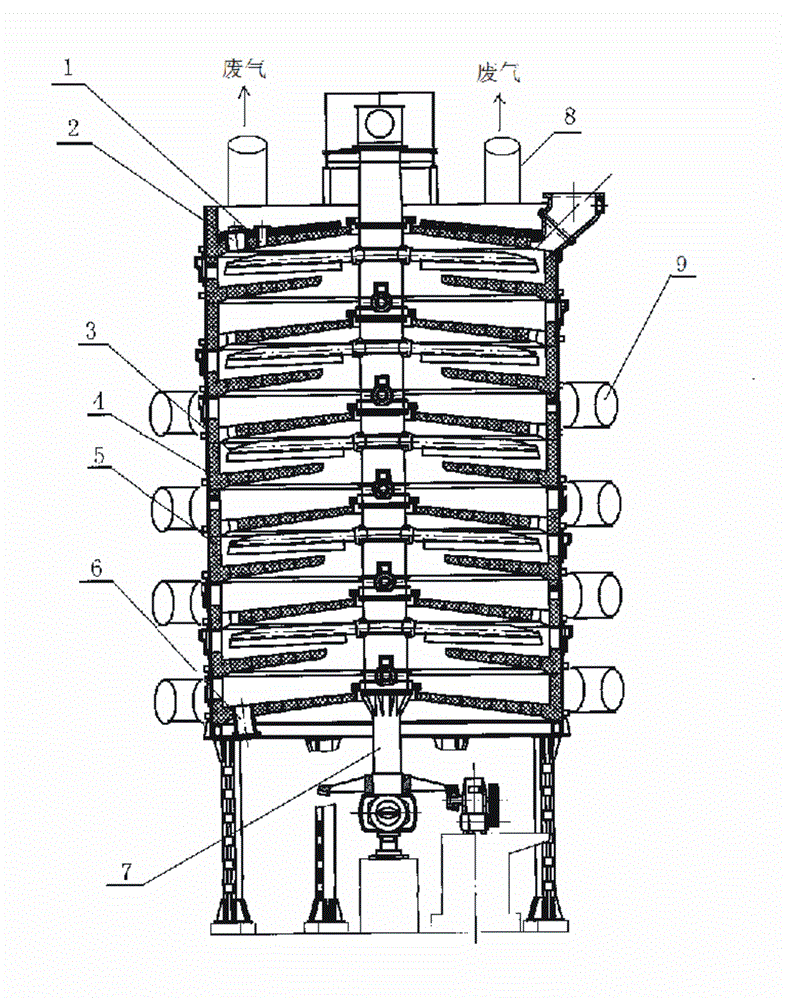

Method used

Image

Examples

Embodiment 1

[0035] A dry reduction and detoxification process for chromium slag, fully mixing chromium slag (a chromium slag with a particle size of less than 1 mm in Qujing, Yunnan, with a CrⅥ content of 2.09% and a Fe content of 28.5%) with coal powder, and the particle size of the coal powder is less than 3 mm , the mass ratio of coal powder to chromium slag is 2:100, under airtight conditions, the obtained mixture is evenly fed into the reaction furnace through a star feeder, and the following process is completed:

[0036] 1) Dehydration: The mixture is in the state of stirring, and the neutral or oxidative atmosphere is controlled, and the temperature of the first layer is 200 ° C for 5.5 minutes of dehydration and drying;

[0037]2) Preheating: the dehydrated and dried mixture is in the state of stirring, at a temperature of 300 ℃ ~ 400 ℃, use preheating to reduce the exhaust gas, and pre-reduce for 11 minutes;

[0038] 3) Roasting: The preheated mixture is roasted in a reducing at...

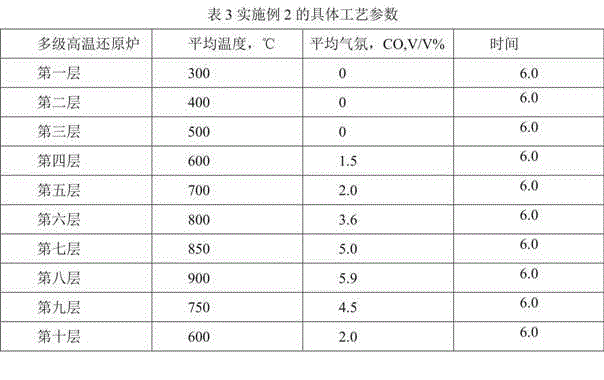

Embodiment 2

[0044] A dry reduction and detoxification process for chromium slag, fully mixing chromium slag (a chromium slag with a particle size of less than 0.5mm in Qujing, Yunnan, with a CrⅥ content of 1.78% and a Fe content of 32.5%) with coal powder, and the particle size of the coal powder is less than 3 mm, the mass percentage of pulverized coal accounts for 3% of the total amount of the two. Under airtight conditions, the resulting mixture is evenly fed into the reaction furnace through a screw feeder to complete the following process:

[0045] 1) Dehydration: The mixture is in the state of stirring, and the neutral or oxidative atmosphere is controlled, and the first layer is dehydrated and dried for 6 minutes at a temperature of 200 ° C ~ 300 ° C;

[0046] 2) Preheating: the dehydrated and dried mixture is in the state of stirring, and at a temperature of 350 ° C ~ 500 ° C, the waste gas is reduced by preheating for 12 minutes;

[0047] 3) Roasting: The preheated mixture is roa...

Embodiment 3

[0053] A dry reduction and detoxification process for chromium slag, fully mixing chromium slag (Hubei Huangshi Zhenhua Chemical Industry chromium slag with a particle size of less than 1mm, CrⅥ content of 1.68%, and Fe content of 12.5%) with coal powder, and the particle size of coal powder is less than 3 mm, and the mass percentage of pulverized coal accounts for 2.5% of the total amount of the two. Under airtight conditions, the obtained mixture is evenly fed into the reaction furnace through a screw feeder to complete the following process:

[0054] 1) Dehydration: The mixture is in the state of stirring, and the neutral or oxidative atmosphere is controlled, and the dehydration is carried out at 250°C for 5.0 minutes;

[0055] 2) Preheating: The dehydrated and dried mixture is in the state of stirring, at a temperature of 350 ℃ ~ 480 ℃, use preheating to reduce the exhaust gas, and pre-reduce for 10 minutes;

[0056] 3) Roasting: The preheated mixture is roasted in a redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com