Mg-Li magnesium alloy and preparation method thereof

A technology of magnesium alloys and polymers, applied in prosthetics, coatings, medical science, etc., can solve the problems of increased strength of alloys at room temperature, reduced strength of alloys and corrosion resistance, etc., to improve low plasticity, make up for strength and Insufficient effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1. Preparation of Mg-Li-(Al, RE) alloy

[0047] The test materials used pure Mg (99.9wt.%), Li (99.9wt.%), Al (99.95wt.%) and RE (99.8wt.%).

[0048] Weigh the materials according to the following proportions:

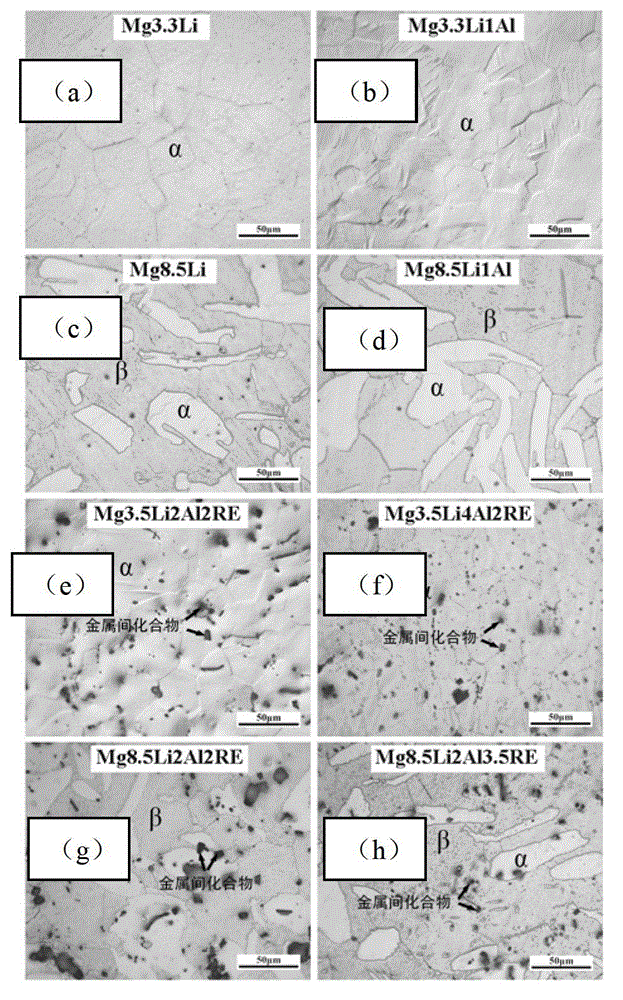

[0049] (A) Li 3.3% and the balance of Mg; (b) Li 3.3%, Al 1% and the balance of Mg; (c) Li 8.5% and the balance of Mg; (d) Li 8.5%, Al 1% And the balance of Mg; (e) Li 3.5%, Al 2%, RE 2% and the balance of Mg; (f) Li 3.5%, Al 4%, RE 2% and the balance of Mg; (g) Li 8.5%, Al 2%, RE 2% and the balance of Mg; (h) Li 8.5%, Al 2%, RE 3.5% and the balance of Mg;

[0050] Place the small magnesium ingot in a crucible and melt it under the protection of argon, then add the remaining components weighed above to the molten Mg, stir for 5 minutes, quickly heat the melt to about 720°C, keep it warm and keep it still After 30 minutes, pour the melt into a mold preheated to 300℃, polish the gate, anneal at 250℃ for 12 hours, and extrude at 280℃, the extrusion rate is 0.5m / m...

Embodiment 2

[0053] Example 2. Room temperature tensile properties of Mg-Li-(Al, RE) alloy

[0054] The Mg-Li-(Al, RE) alloy prepared in Example 1 was prepared according to the ASTM-E8-04 tensile test standard to prepare tensile samples, SiC water-resistant sandpaper was polished to 2000#, and the room temperature tensile test was carried out using a universal tensile testing machine , The stretching speed is 1mm / min.

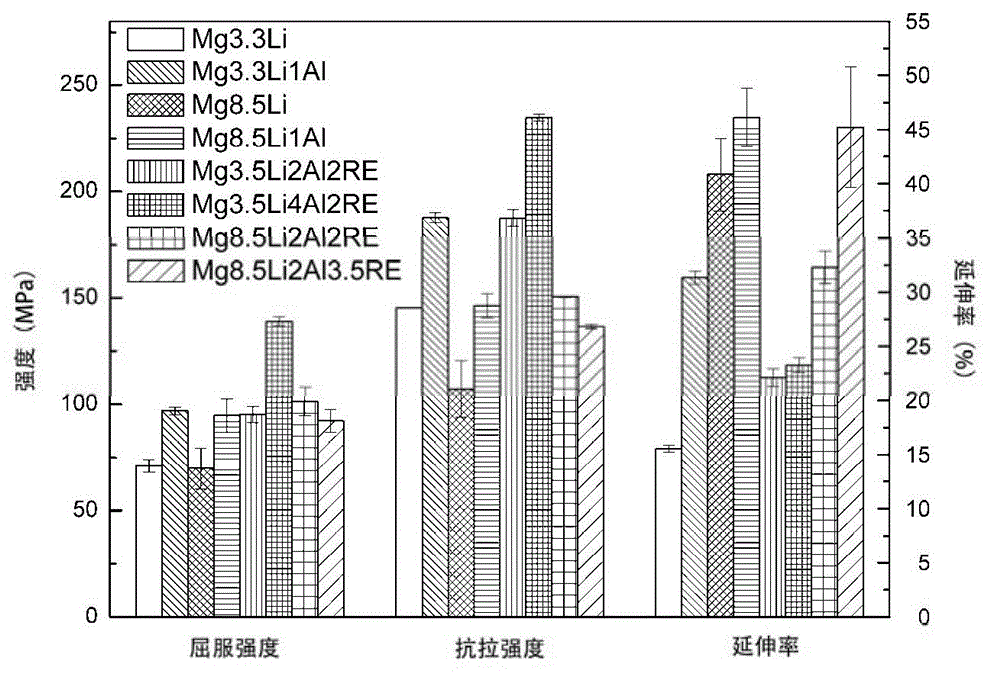

[0055] The room temperature tensile properties of the Mg-Li-(Al, RE) alloy prepared by the invention are as follows figure 2 Shown by figure 2 It can be seen that with the increase of Li content, the yield strength and tensile strength of the alloy have decreased, and the elongation has been greatly improved. The addition of aluminum improves the mechanical strength and elongation of the alloy, and the addition of rare earth elements improves the yield strength and tensile strength of the alloy, but has little effect on the elongation.

Embodiment 3

[0056] Example 3 Corrosion resistance of Mg-Li-(Al, RE) alloy

[0057] Wire the Mg-Li-(Al, RE) alloy prepared in Example 1 into The disc-shaped sample of the sample was polished with sandpaper to 2000#. The electrochemical test was then carried out in Hank’s simulated body fluid at 37°C.

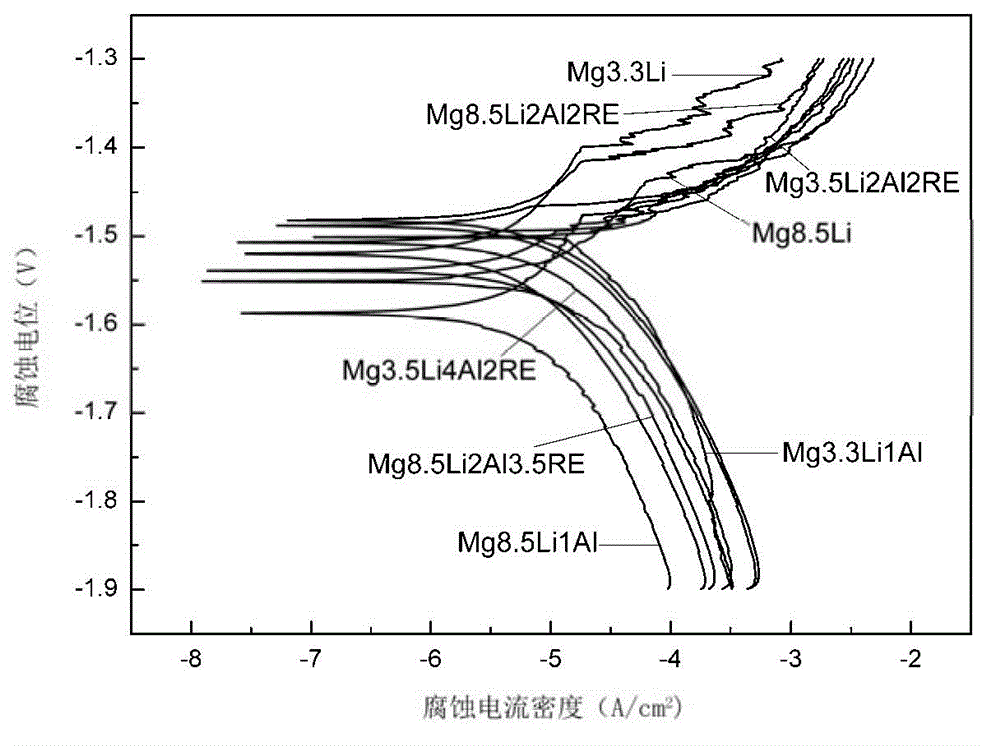

[0058] The corrosion potential-corrosion current curve of the Mg-Li-(Al, RE) alloy obtained by the present invention is as follows image 3 Shown.

[0059] The corrosion potential-corrosion current curve of the Mg-Li-(Al, RE) alloy prepared by the invention is as follows image 3 As shown, the analysis of the figure shows that for the alloy without the addition of RE element, as the content of Li element increases, the corrosion resistance of the alloy decreases, which is manifested as a decrease in corrosion potential and an increase in corrosion current; the addition of Al element causes The decrease of alloy corrosion current improves the corrosion resistance of alloy. For magnesium alloys wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com