Energy-saving and environment-friendly spray drying system

A drying system, energy saving and environmental protection technology, applied in the direction of spray evaporation, evaporator accessories, etc., can solve the problems of heavy metal and sulfur content increase, atmospheric environmental pollution, air pollution, etc., to save energy, protect the environment, avoid emissions or losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

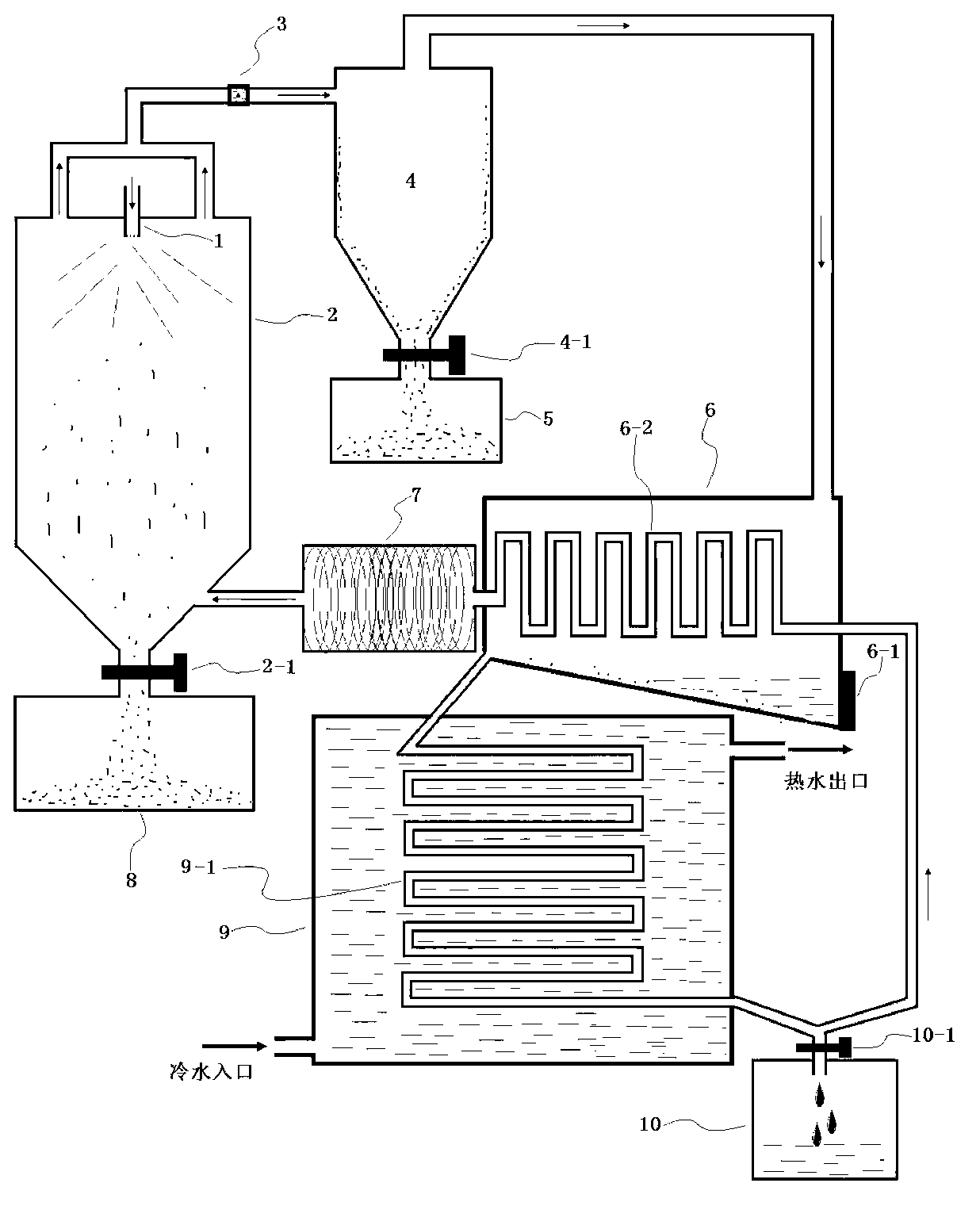

[0021] Such as figure 1 Shown, a kind of energy-saving and environment-friendly spray drying system comprises condensed water tank 9, also comprises spray drying chamber 2, cyclone separator 4, heat exchange chamber 6, heater 7 and solvent recovery tank 10, and spray drying chamber 2 is separated from cyclone The cyclone separator 4 is connected to the heat exchange chamber 6, the heat exchange chamber 6 is provided with a heat exchange pipe 6-2, the condensation water tank 9 is provided with a condensation pipe 9-1, and one end of the heat exchange pipe 6-2 is heated The device 7 is connected with the spray drying chamber 2, and the other end of the heat exchange pipe 6-2 is respectively connected with one end of the condensation pipe 9-1 and the solvent recovery tank 10, and the other end of the condensation pipe 9-1 is connected with the bottom of the heat exchange chamber 6, and the spray drying chamber 2 The upper part is provided with a nozzle 1, the lower part is connec...

Embodiment 2

[0029] Material: 70% ethanol extract of vine tea flavonoids.

[0030] First turn on the high-pressure air pump 3, and then turn on the heater 7. When the air temperature in the spray drying chamber 2 reaches 200 degrees Celsius, the nozzle 1 is opened, and the mist solution is sprayed. The flavone powder falls into the second dry finished product collection box 8, and the ethanol solution is then vaporized and forms a mixed hot air flow together with the hot air, and a small amount of powder that has not been completely settled in the mixed hot air flow is further separated in the cyclone separator, and falls Into the first dry product collection box 5, the mixed hot air flow comes out from the cyclone separator 4 and enters the heat exchange chamber to transfer heat to the gas in the lower heat exchange tube 6-2 of the temperature; in the heat exchange chamber 6, a small amount of ethanol Steam and water vapor are condensed into a liquid mixed solution due to cooling and stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com