Method for improving photocatalytic activity of bismuth tungstate through excessive Bi source

A photocatalyst, trace technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as unfavorable catalyst recycling and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

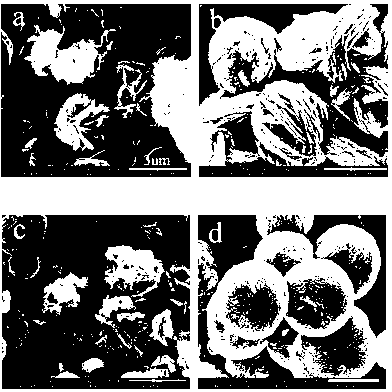

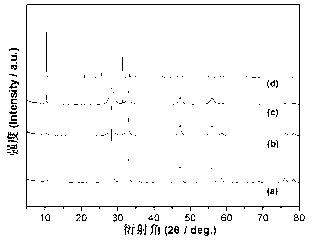

Embodiment 1

[0044] Weigh 0.4075 g (0.84 mmol) Bi(NO 3 ) 3 ·5H 2 Add 7 mL of distilled water to 25 mL of polytetrafluoroethylene lining and stir magnetically, then weigh 0.1319 g (0.40 mmol) of Na 2 WO 4 2H 2 O and dissolved in 10mL of water, then drop it into the above Bi(NO 3 ) 3 the precursor solution. After continuing to stir for 30 min, the resulting white suspension was hydrothermally reacted at 160 °C for 12 h. After naturally cooling to room temperature, the product was centrifuged, washed and dried to obtain a pale yellow photocatalyst powder with a Bi:W molar ratio of 2.1:1. By adjusting the molar ratio of the reactants and repeating the above operations, a series of Bi and W with different molar ratios can be obtained 2 WO 6 base photocatalyst.

Embodiment 2

[0046] Weigh 0.4463 g (0.92mmol) Bi(NO 3 ) 3·5H 2 Add 7mL of distilled water to 25mL of polytetrafluoroethylene lining and stir magnetically, then weigh 0.1319g (0.4mmol) of Na 2 WO 4 2H 2 O and dissolved in 10mL of water, then drop it into the above Bi(NO 3 ) 3 the precursor solution. After continuing to stir for 30 min, the resulting white suspension was hydrothermally reacted at 180 °C for 12 h. After naturally cooling to room temperature, the product was centrifuged, washed and dried to obtain a pale yellow photocatalyst powder with a Bi:W molar ratio of 2.3:1. By adjusting the molar ratio of the reactants and repeating the above operations, a series of Bi and W with different molar ratios can be obtained 2 WO 6 base photocatalyst.

Embodiment 3

[0047] Embodiment 3 preparation method is the same as embodiment 1, the method for 2

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com