Hydrophobic modification treatment method of a kind of zeolite molecular sieve

A zeolite molecular sieve and hydrophobic modification technology, which is applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complex treatment process, large pollution, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

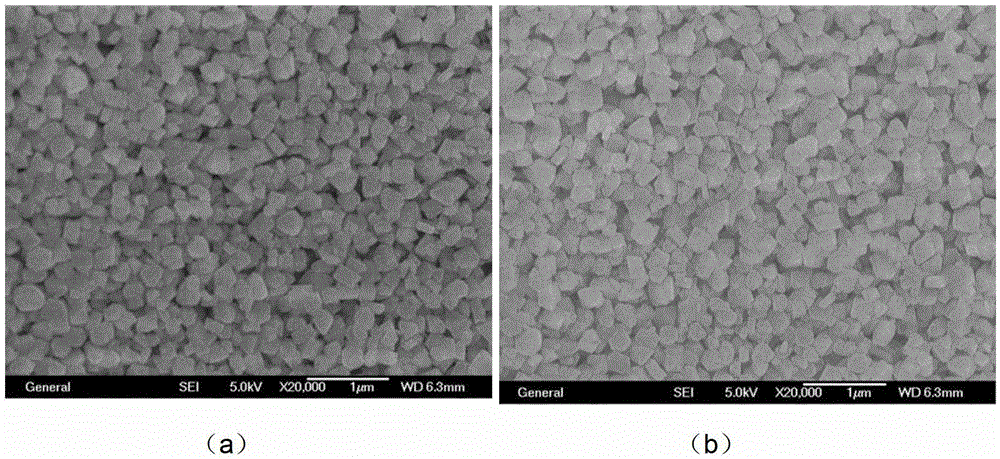

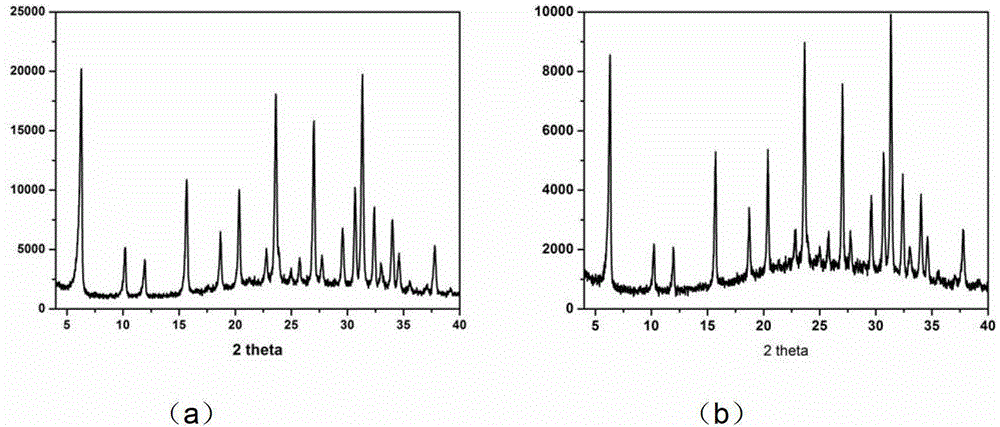

Image

Examples

Embodiment 1

[0022] High temperature activation of nanoporous zeolite molecular sieves:

[0023] Take 500g of NaY type zeolite (Luoyang Jianlong Chemical Industry, fine powder, 25kg industrial packaging,) and put it into a ceramic crucible, wash the molecular sieve with deionized water until it is neutral, bake it at 150°C for 15 hours, put the dried molecular sieve into Put it into a muffle furnace, activate it at 500°C for 5 hours, then cool it down to room temperature to obtain an activated molecular sieve, take it out and store it in a desiccator. The activated molecular sieve has strong hygroscopicity and should be stored in a desiccator if not in use for a long time.

[0025] Add CaH to toluene under nitrogen 2 Stir overnight to obtain dry toluene.

[0026] Links to couplers:

[0027] Take 50g of activated zeolite, add it to a 500mL single-necked flask, add 300mL of dry toluene, pipette 10mL of methyltrimethoxysilane into the single-necked flask, and r...

Embodiment 2

[0032] Hydrophobic molecular sieves were prepared according to the method in Example 1, and 60 mL of coupling agent methyltrimethoxysilane was added. The contact angle of the sample was measured to be 146 degrees.

Embodiment 3

[0034] Hydrophobic molecular sieves were prepared according to the method in Example 1. Added methyltrimethoxysilane 30mL. The contact angle of the sample was measured to be 140 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com