Novel co-frame organic framework material and preparation method and application thereof

An organic framework and co-frame technology, which is applied in the field of novel co-frame organic framework materials and their preparation, can solve the problems of poor conductivity of two-dimensional COFs, low capacity of supercapacitor electrode materials, and low nitrogen doping content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of novel co-framed organic framework materials

[0033] Add hexaaminotriphenylene and cyclohexanone in a molar ratio of 1:3 to H + In acidic ethanol with a volume fraction of 10%, after ultrasonic mixing, reflux reaction at 200°C for 60h, then wash with ethanol, and finally centrifuge to obtain the solid phase, vacuum-dry the solid phase at 80°C to constant weight to obtain brown-gray powder to prepare a new co-framed organic framework material.

Embodiment 2

[0035] Preparation of novel co-framed organic framework materials

[0036] Add hexaaminotriphenylene and cyclohexanone in a molar ratio of 1:3 to H + In acidic ethanol with a volume fraction of 10%, after ultrasonic mixing, reflux reaction at 180°C for 50h, then wash with ethanol, and finally centrifuge to obtain the solid phase, vacuum-dry the solid phase at 80°C to constant weight, and obtain brown-gray powder to prepare a new co-framed organic framework material.

Embodiment 3

[0038] Preparation of novel co-framed organic framework materials

[0039] Add hexaaminotriphenylene and cyclohexanone in a molar ratio of 1:3 to H + In acidic ethanol with a volume fraction of 10%, after ultrasonic mixing, reflux at 180°C for 72h, then wash with ethanol, and finally centrifuge to obtain the solid phase, vacuum dry the solid phase at 80°C to constant weight, and obtain brown-gray powder to prepare a new co-framed organic framework material.

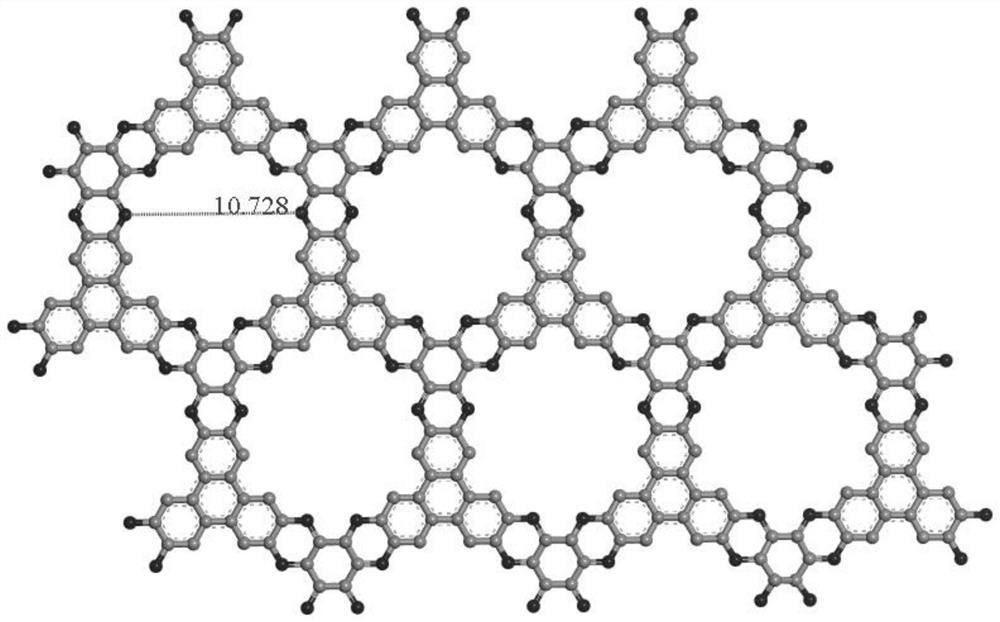

[0040] figure 1 It is a schematic diagram of the molecular structure of the novel co-frame organic framework material in the present invention, consisting of figure 1 It can be seen that the material structure is a completely planar two-dimensional structure and a highly symmetrical periodic structure with holes, with approximately The left and right periodic channels, and a large number of nitrogen active sites.

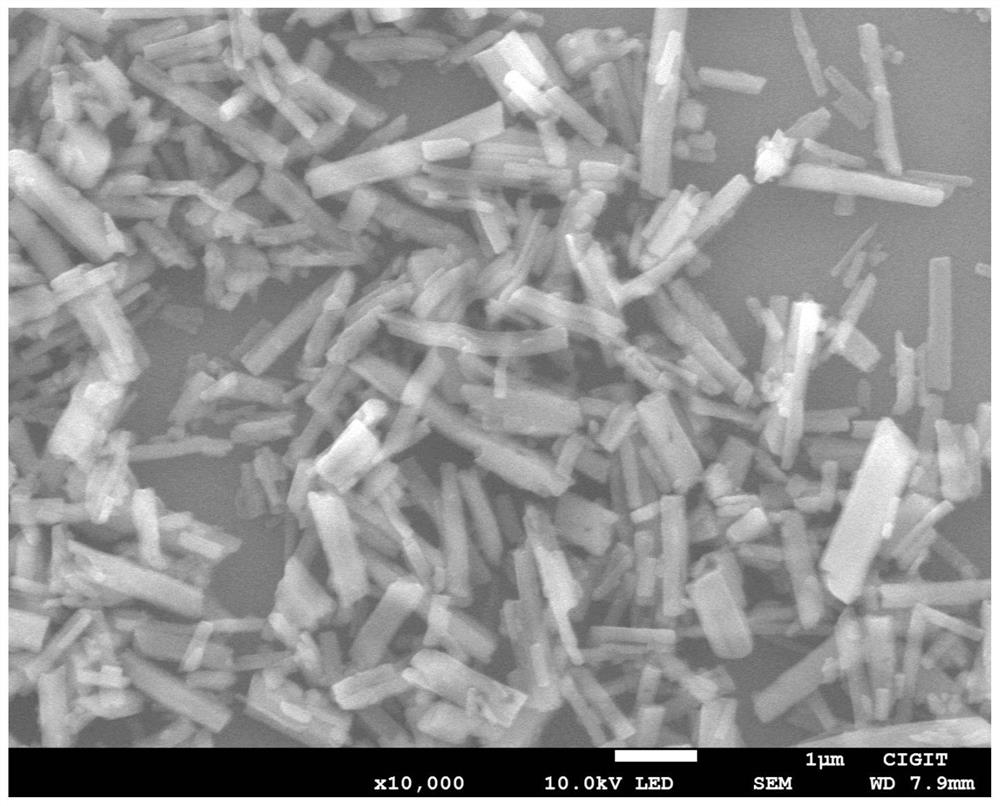

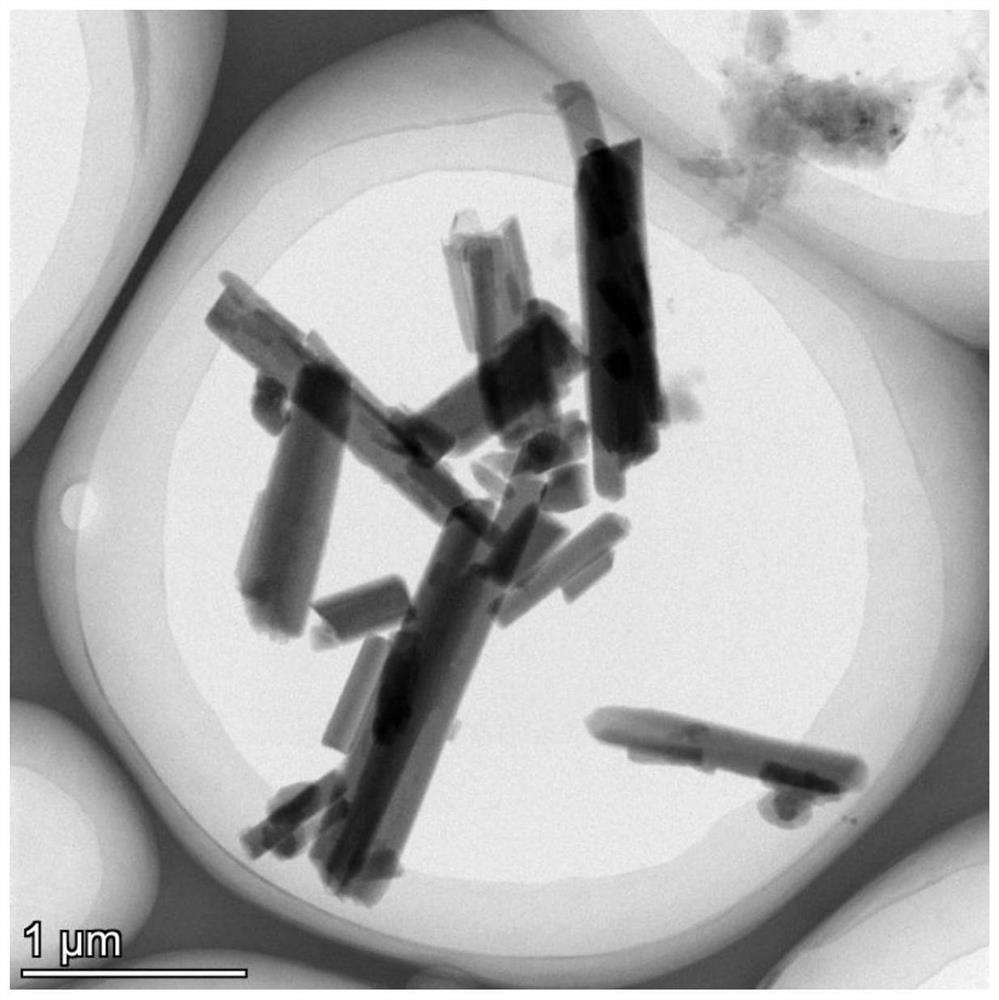

[0041] figure 2 It is the SEM picture of the novel co-frame organic framework material prepared in Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com