Hydrogenation catalyst for sulfur-containing waste gas treatment and application thereof

A hydrogenation catalyst and exhaust gas treatment technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as insufficient hydrogenation activity and desulfurization activity, high catalyst production costs, and affecting economic benefits. Achieve the effect of improving activation efficiency, improving pore properties, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

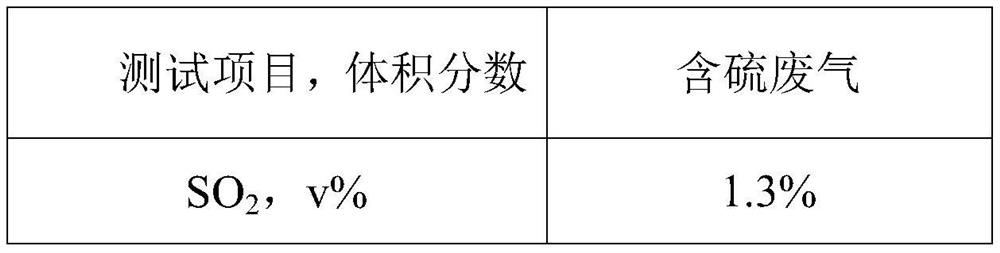

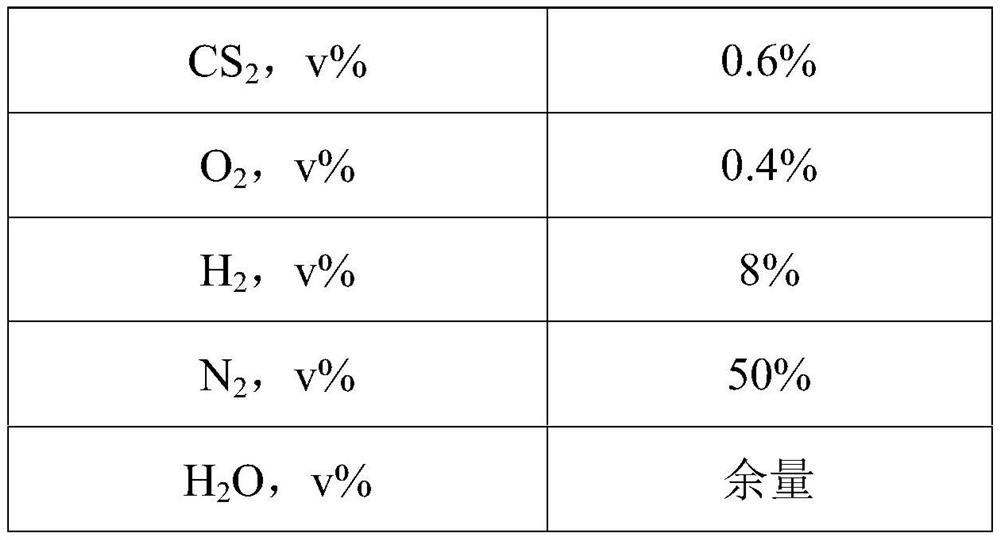

Image

Examples

Embodiment 1

[0018] A hydrogenation catalyst for treating sulfur-containing waste gas, the preparation method of which comprises:

[0019] S1, 5gY type molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 15, the unit cell parameter is 2.45nm, and the crystallization retention rate is greater than 95%) is added in 100mL of ammonium nitrate solution (10wt%), stirred at 100°C for 2h, filtered and washed with deionized water, and dried at 120°C for 16h, Obtain ammonia type molecular sieve;

[0020] S2. Add the above-mentioned ammonia-type molecular sieve to the mixed solution of cobalt nitrate and ammonium molybdate (specifically, 0.4716g cobalt nitrate hexahydrate and 0.7874g ammonium heptamolybdate tetrahydrate are dissolved in 10mL deionized water), stir well and then ultrasonic 0.5h, then impregnated at room temperature for 5h, then dried at 100°C for 8h, then placed in a muffle furnace, and roasted at 500°C for 6h to obtain a catalyst precursor;

[0021] S3. Add the above-mentioned ca...

Embodiment 2

[0023] A hydrogenation catalyst for treating sulfur-containing waste gas, the preparation method of which comprises:

[0024] S1, 5gY type molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 15, the unit cell parameter is 2.45nm, and the crystallization retention rate is greater than 95%) is added in 100mL of ammonium nitrate solution (10wt%), stirred at 100°C for 2h, filtered and washed with deionized water, and dried at 120°C for 16h, Obtain ammonia type molecular sieve;

[0025] S2. Add the above ammonia-type molecular sieve to the mixed solution of nickel nitrate and ammonium molybdate (specifically, add 0.4738g nickel nitrate hexahydrate and 0.7874g ammonium heptamolybdate tetrahydrate into 10mL deionized water to dissolve), stir well and then ultrasonic 0.5h, then impregnated at room temperature for 5h, then dried at 100°C for 8h, then placed in a muffle furnace, and roasted at 500°C for 6h to obtain a catalyst precursor;

[0026] S3. Add the above-mentioned catalyst...

Embodiment 3

[0028] A hydrogenation catalyst for treating sulfur-containing waste gas, the preparation method of which comprises:

[0029] S1, 5gY type molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 15, the unit cell parameter is 2.45nm, and the crystallization retention rate is greater than 95%) is added in 100mL of ammonium nitrate solution (10wt%), stirred at 100°C for 2h, filtered and washed with deionized water, and dried at 120°C for 16h, Obtain ammonia type molecular sieve;

[0030] S2. Add the above-mentioned ammonia-type molecular sieve to the mixed solution of nickel nitrate and ammonium metatungstate (specifically, add 0.4738g of nickel nitrate hexahydrate and 1.1596g of ammonium metatungstate hexahydrate into 10mL of deionized water to dissolve), and stir evenly Ultrasound for 0.5h, then impregnated at room temperature for 5h, then dried at 100°C for 8h, then placed in a muffle furnace, and calcined at 500°C for 6h to obtain a catalyst precursor;

[0031] S3. Add the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com