A kind of method of Y-type molecular sieve hydrophobic modification

A hydrophobic modification and molecular sieve technology, which is applied in the directions of crystalline aluminosilicate zeolite, fajhedral crystalline aluminosilicate zeolite, etc., can solve the problems of poor effect and complicated hydrophobic modification method of Y-type molecular sieve, and achieves the technical solution and Clear effect, avoid handling problems, high crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

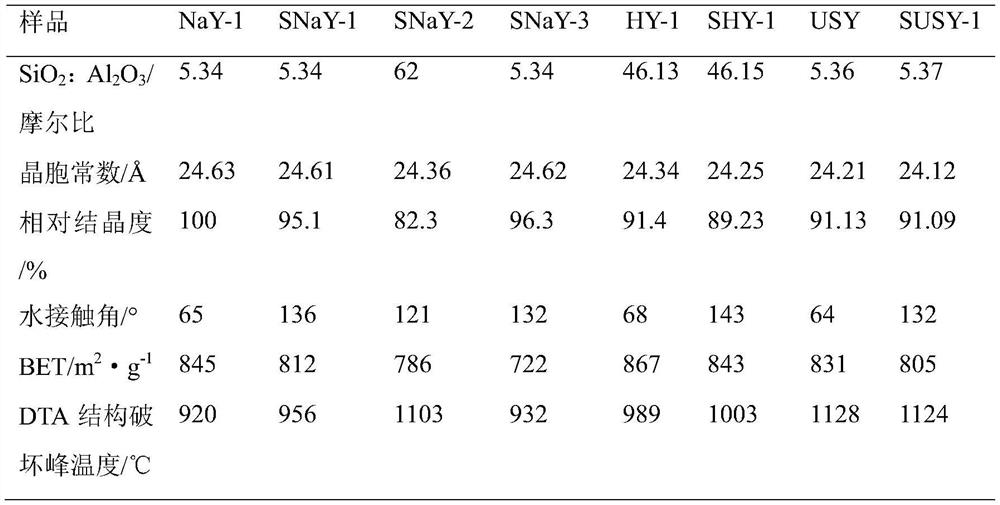

Embodiment 1

[0031] NaY molecular sieve raw material (Nankai Catalyst Factory, SAR=5.6) is made into 100-200 mesh particles, placed in a quartz reaction tube, under 100ml / min nitrogen flow, the reaction time is 2h at 450°C, and the adsorption water and Bound water; pass nitrogen flow containing trimethylchlorosilane to react with Y-type molecular sieve after high temperature activation, space velocity 250h -1 , the reaction temperature is 350°C, and the reaction time is 4h; cut off the feeding of the nitrogen flow of the coupling agent, and instead feed oxygen into the silanized Y-type molecular sieve with a space velocity of 100h -1 , the reaction temperature is 550° C., and the reaction time is 4 hours; then the oxidized granular product is washed and dried with ethanol and deionized water to obtain a hydrophobic zeolite molecular sieve. The unhydrophobized sample was recorded as NaY-1, and the hydrophobized sample was recorded as SNaY-1. The properties are listed in Table 1.

Embodiment 2

[0033]HY molecular sieves (Huaxin Catalyst Factory, SAR=40) were made into 100-200 mesh particles, placed in a quartz reaction tube, and the reaction time was 2h under 100ml / min nitrogen flow, 550°C, and dried to remove adsorbed water and Bound water; pass through a nitrogen flow containing methyltrimethoxysilane to react with Y-type molecular sieve activated at high temperature, and the space velocity is 200h -1 , the reaction temperature is 250°C, and the reaction time is 2h; cut off the nitrogen flow of the coupling agent, and change to feed oxygen into the silanized Y-type molecular sieve, with a space velocity of 80h -1 , the reaction temperature is 600° C., and the reaction time is 2 hours; then the oxidized granular product is washed and dried with ethanol and deionized water to obtain a hydrophobic zeolite molecular sieve. The unhydrophobized sample is marked as HY-1, and the hydrophobized sample is marked as SHY-1. The properties are listed in Table 1.

Embodiment 3

[0035] Hydrophobic Y molecular sieves were prepared according to the method in Example 1. The Y-type molecular sieve used is USY, the unhydrophobized sample is marked as USY-1 (Nankai Catalyst Factory, SAR=5.6), and the hydrophobized sample is marked as SUSY-1, and the properties are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com