Modified macroporous material and preparation method thereof

A macroporous material and modification technology, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve problems such as single pore structure, achieve the effects of cheap raw materials, improved pore properties, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 50 grams of volcanic rock and place it in a beaker, add 500 mL of aluminum nitrate solution with a mass concentration of 30% to the beaker and soak for 1 hour to make the volcanic rock adsorb and saturate. The roasted material was impregnated twice in the same way.

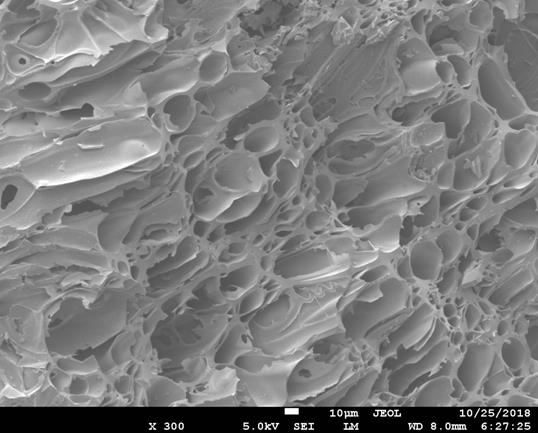

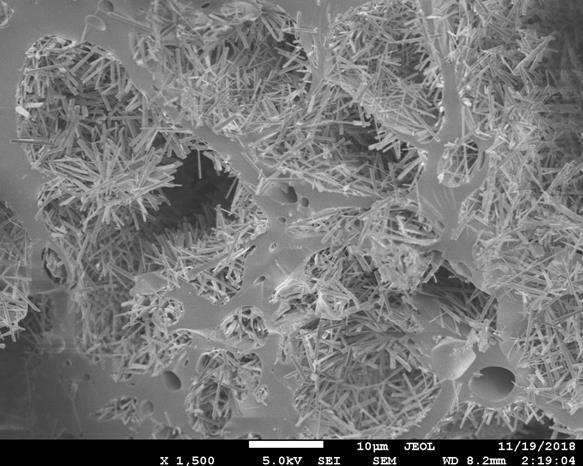

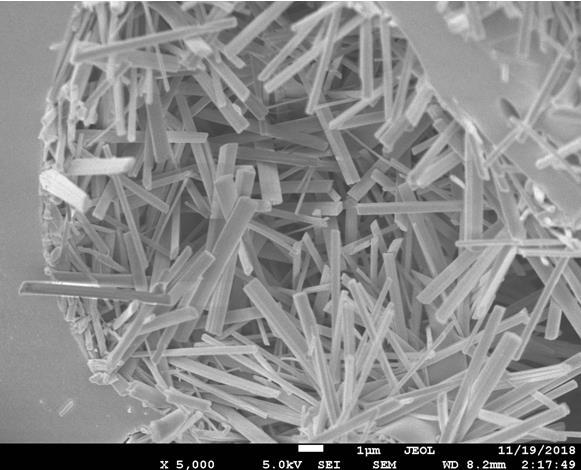

[0029] Weigh 10 grams of the above-mentioned treated volcanic rock and place it in 55 grams of ammonium bicarbonate aqueous solution with a mass concentration of 18.5%, transfer the mixed material into an autoclave and seal it, heat it at 140°C for 5.5 hours, and then dry the carrier at 110°C for 6 hours The modified macroporous material A1 was obtained by roasting at 600°C for 4 hours. The properties of the material are shown in Table 1. The scanning electron microscope photos are as follows: figure 2 , 3 As shown,.

Embodiment 2

[0031] With embodiment 1, just the mass concentration of aluminum nitrate is 35%, and the consumption of ammonium bicarbonate solution is 65 grams during heat treatment, and the mass concentration of solution is 21.5%. The heat treatment temperature was 130° C., and the treatment time was 6.5 hours. The modified macroporous material A2 was prepared, and the properties of the material are shown in Table 1.

Embodiment 3

[0033] Same as Example 1, except that the mass concentration of aluminum nitrate is 40%, the number of times of impregnating aluminum salt is 2 times, the consumption of ammonium bicarbonate solution is 75 grams during heat treatment, and the mass concentration of solution is 15.5%. The heat treatment temperature was 120° C., and the treatment time was 7.5 hours. The modified macroporous material A3 was obtained, and the properties of the material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com