Recovery process and separation device of toluene solvent in production process of alpha-acetyl-gamma butyrolactone

A production process, the technology of butyrolactone, applied in the process, the equipment field of this process, to achieve the effect of reducing cost, reducing the temperature of the tower kettle, saving equipment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

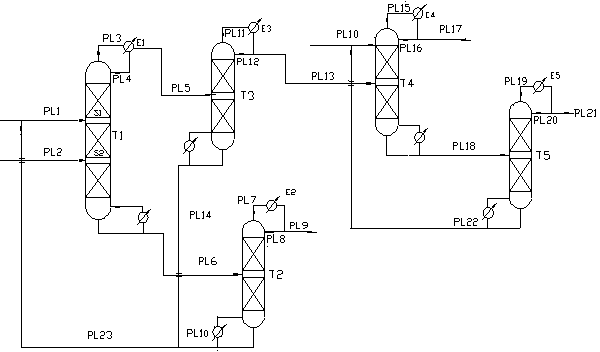

[0041] Attached figure 1 In the process flow shown, the upper section of the toluene extractive distillation tower is the rectification section, the middle section is the extractive distillation section, and the lower section is the stripping section. The material of the entire tower body is Q235 / 304. The section is filled with CY wire mesh packing, the packing height of the toluene extractive distillation tower T1 is 22m, the height of the rectification section is 3m, the height of the extractive distillation section is 15m, and the height of the stripping section is 4m. The whole tower body of the ketone extractant recovery tower is made of Q235 / 304, which is divided into a rectification section and a stripping section. The tower is filled with CY wire mesh packing. The height of the packing is 10m, the height of the rectification section is 5m, and the stripping section The height is 5m. The material of the entire tower body of the toluene secondary extractive distillation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com