Wax cleaning agent for hot water dispensing deep well high-pour point wax

A wax remover, hot water technology, used in cleaning appliances, wellbore/well components, drilling compositions, etc., can solve the problem that the packer cannot be opened, the mechanical wax removal effect is poor, and the packer is not tightly sealed. and other problems, to achieve the effect of prolonging the mining days, convenient and effective construction, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

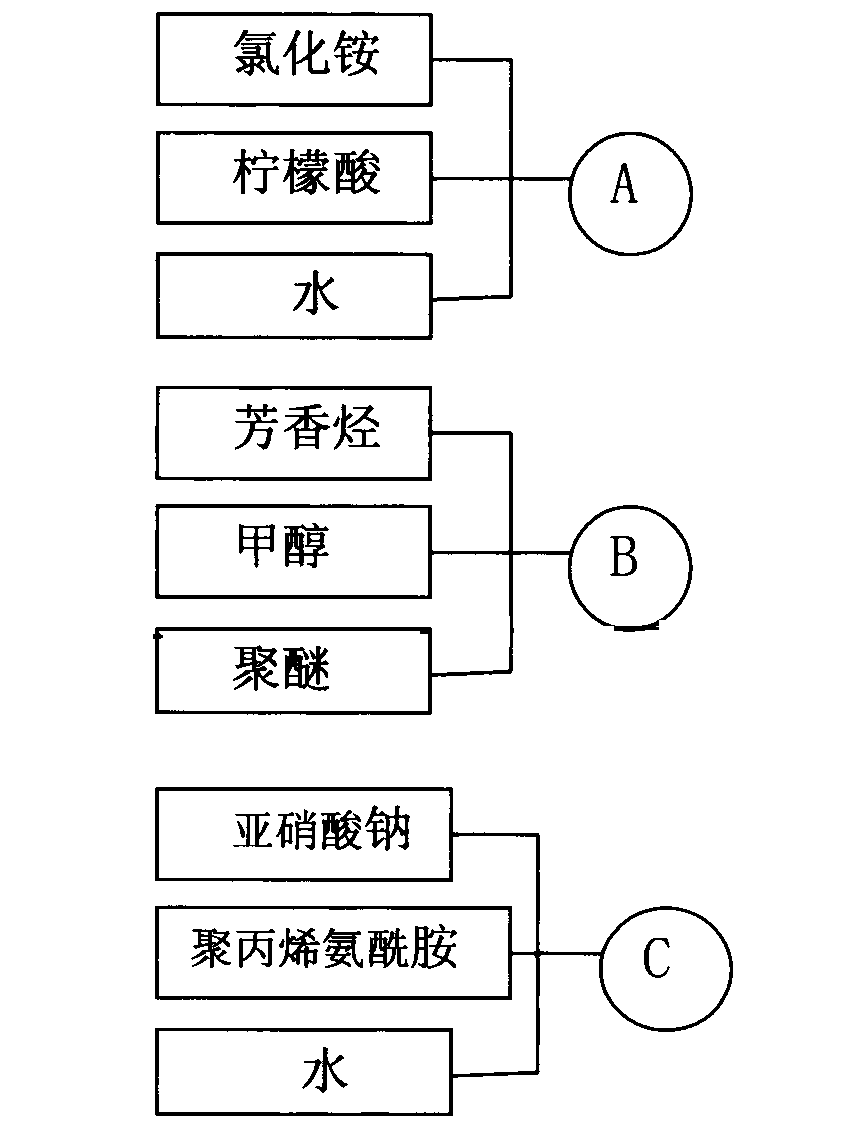

[0014] as attached figure 1 As shown, the wax remover includes three independent components of agents A, B, and C. When used together, the agents A, B, and C are used in sequence;

[0015] The formulas of A, B, and C agents in the foregoing are respectively:

[0016] A agent: ammonium chloride 25-35%, citric acid 1-10%, the rest is water; B agent: aromatic hydrocarbon 60%-80%, methanol 10%-30%, polyether 3%-10%; C agent : Sodium nitrite 40-60%, polyacrylamide 0.2-1%, the rest is water.

[0017] The production process of A, B, and C agents is as follows:

[0018] Agent A: Add hot water to the heated reactor, then add ammonium chloride and citric acid, stir until the agent is completely dissolved, and keep the agent at 50°C;

[0019] Agent B: Add aromatic hydrocarbon, methanol, and polyether to the reaction kettle, and stir evenly.

[0020] Agent C: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com