Electro-slag re-melting slag and preparation method thereof

An electroslag remelting and content technology is applied in the field of metallurgical auxiliary materials to achieve the effects of reducing the introduction of nitrogen, saving the cost of steelmaking, and stabilizing the chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

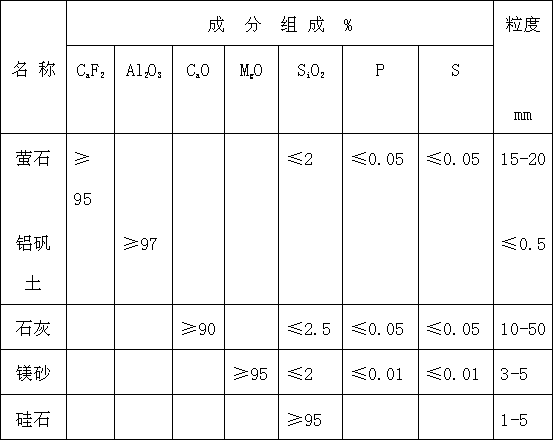

Image

Examples

Embodiment 1

[0029] The electroslag heavy melting slag of the present invention is made up of the raw material of following percentage by weight:

[0030] Fluorite 20%, bauxite 40%, high calcium lime 30%, fused magnesia 5%, silica 5%.

[0031] Its preparation method is:

[0032] ⑴. Inspection: For each raw material, inspect the raw materials that meet the requirements according to the requirements of their respective component contents;

[0033] ⑵.Fine grinding: pass the raw materials that meet the requirements through the crusher and Raymond mill to produce fine powder with a particle size of more than 100 mesh;

[0034] ⑶. Proportion: Mix the above-mentioned fine powders evenly according to the composition ratio;

[0035] ⑷. Ball making: the mixed raw materials are made into balls with a particle size of 10-30mm through a dry pressing ball machine;

[0036] ⑸.Drying: bake the above-mentioned balls with a particle size of 10-30mm;

[0037] ⑹. Electrofusion: Put the baked ball into the...

Embodiment 2

[0045] The electroslag heavy melting slag of the present invention is made up of the raw material of following percentage by weight:

[0046] Fluorite 20%, bauxite 35%, high calcium lime 30%, fused magnesia 5%, silica 10%.

[0047] Its preparation method is with embodiment 1.

Embodiment 3

[0049] The electroslag heavy melting slag of the present invention is made up of the raw material of following percentage by weight:

[0050] Fluorite 25%, bauxite 35%, high calcium lime 30%, fused magnesia 5%, silica 5%.

[0051] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com