Novel skin/core-layer composite fiber as well as preparation method and application thereof

A layer composite, skin-core technology, applied in the field of new skin-core layer composite fiber and its preparation, can solve the problems of electrical conductivity, specific surface area, and flexibility, and achieve superior mechanical properties, improved mechanical and electrical properties, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

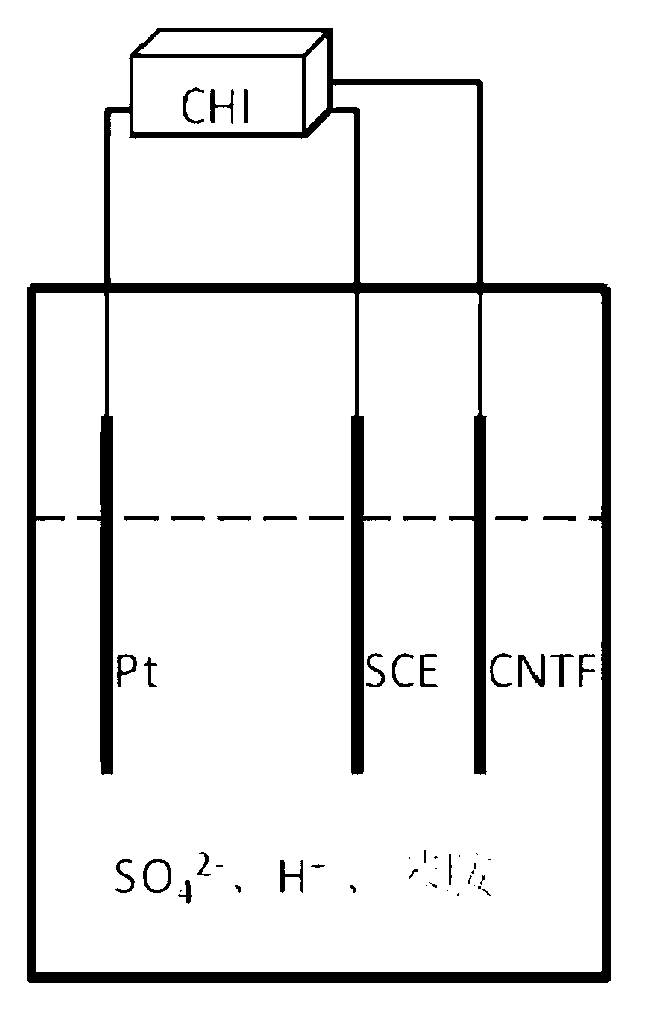

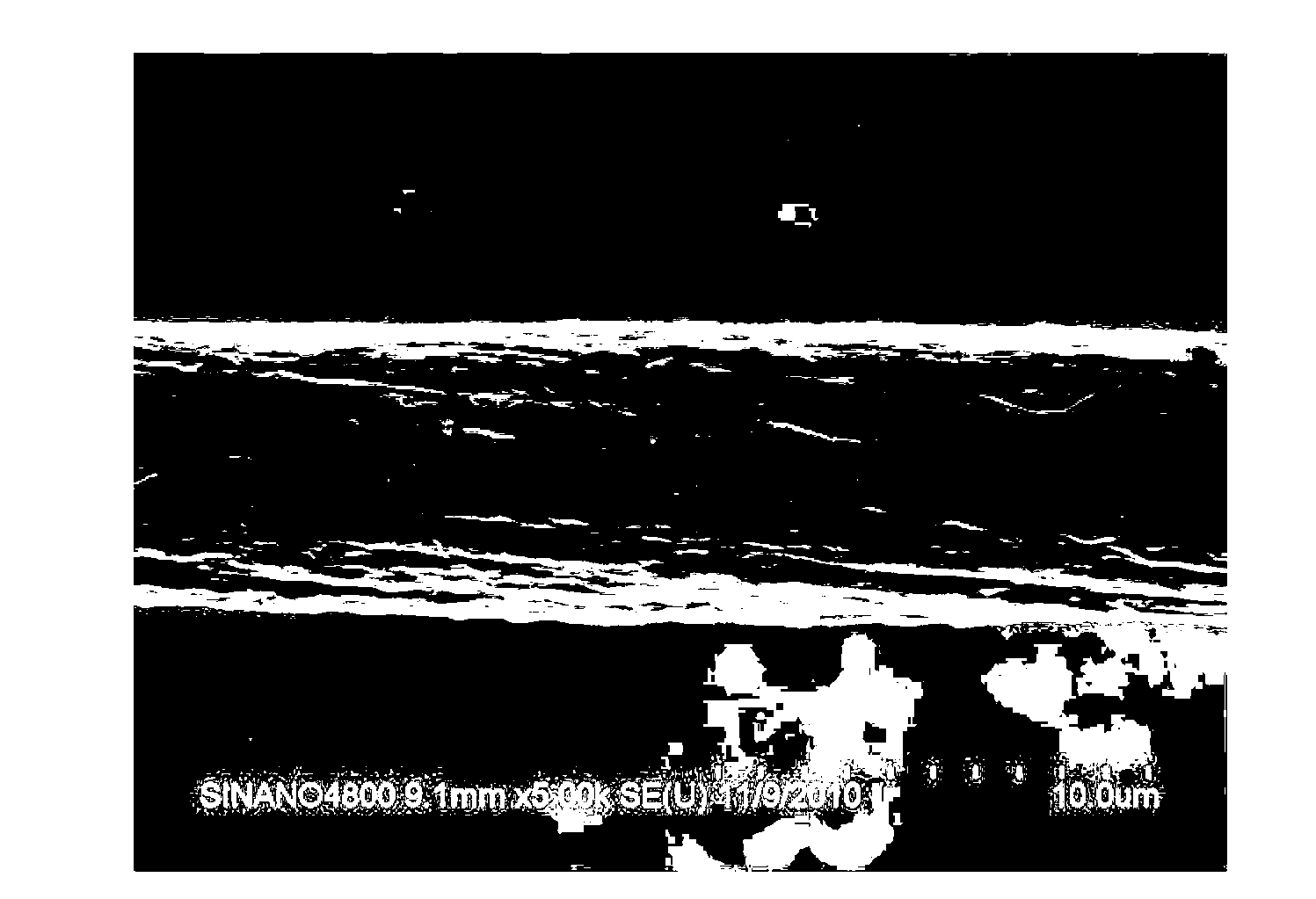

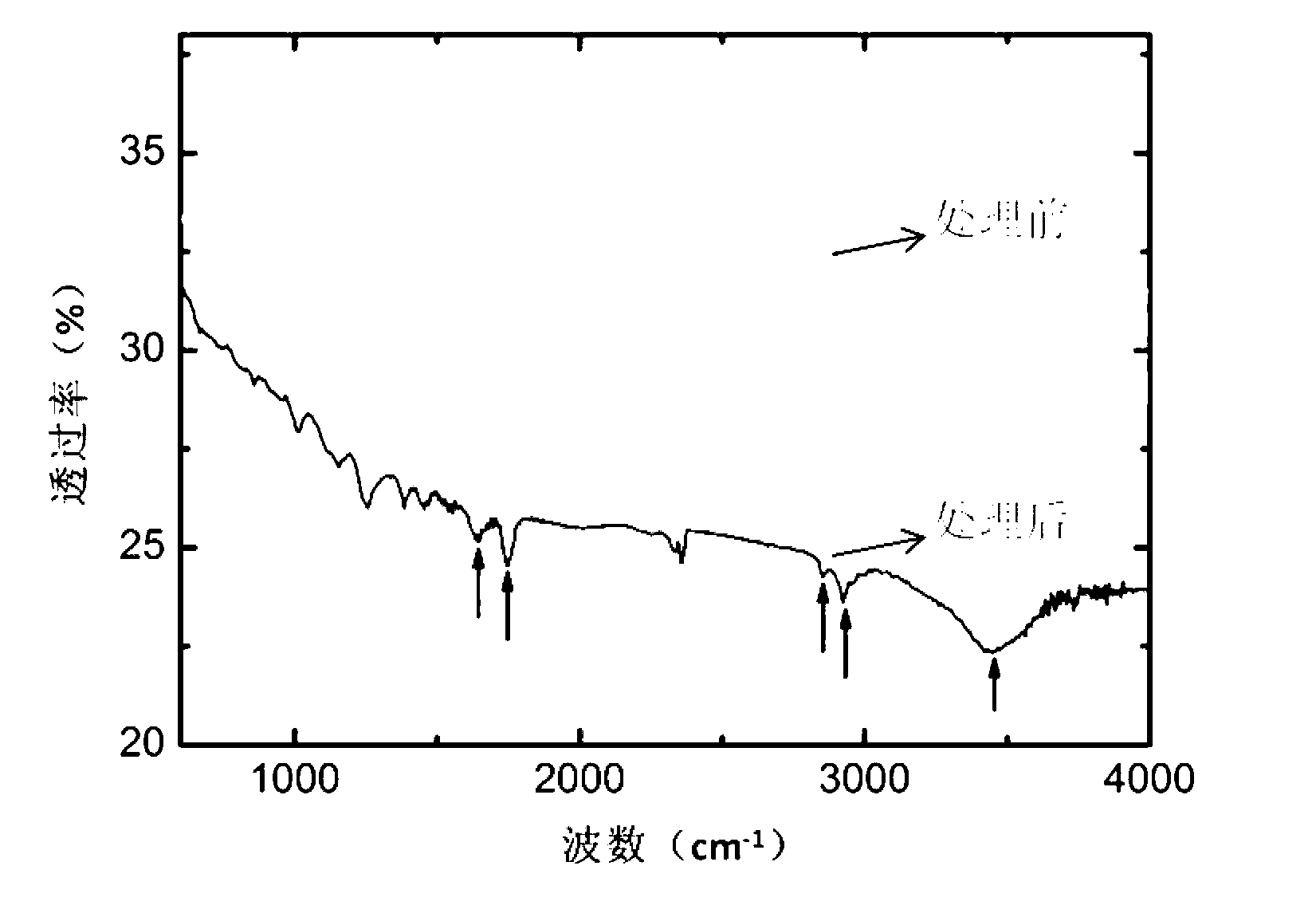

[0050] Example 1 The purpose of this example is to obtain light, flexible, and high-strength line capacitors. The basic technical idea is to chemically treat lightweight carbon nanotube fibers to improve the mechanical and electrical properties of carbon nanotube fibers, and then A conductive polyaniline layer is deposited on the surface of the fiber by an electrochemical method to obtain a bicomponent fiber with a skin-core structure (also known as a new type of skin-core composite fiber).

[0051] The method of obtaining carbon nanotube fibers in this example can be spinnable array spinning method, floating catalytic spinning method, solution spinning method, and the chemical reagents used are mainly concentrated nitric acid, aniline, concentrated sulfuric acid, etc. (can be purchased directly) .

[0052] Taking carbon nanotube fibers prepared by the array spinning method as an example to illustrate the main steps of the preparation process of the line capacitor as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com