Method for manufacturing display device and etching solution composition

A technology of composition and copper alloy layer, which is applied in the direction of surface etching composition, chemical instrument and method, semiconductor/solid-state device manufacturing, etc., can solve the problem that it is difficult to fully etch the metal layer, and achieve the goal of improving productivity and simplifying the manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

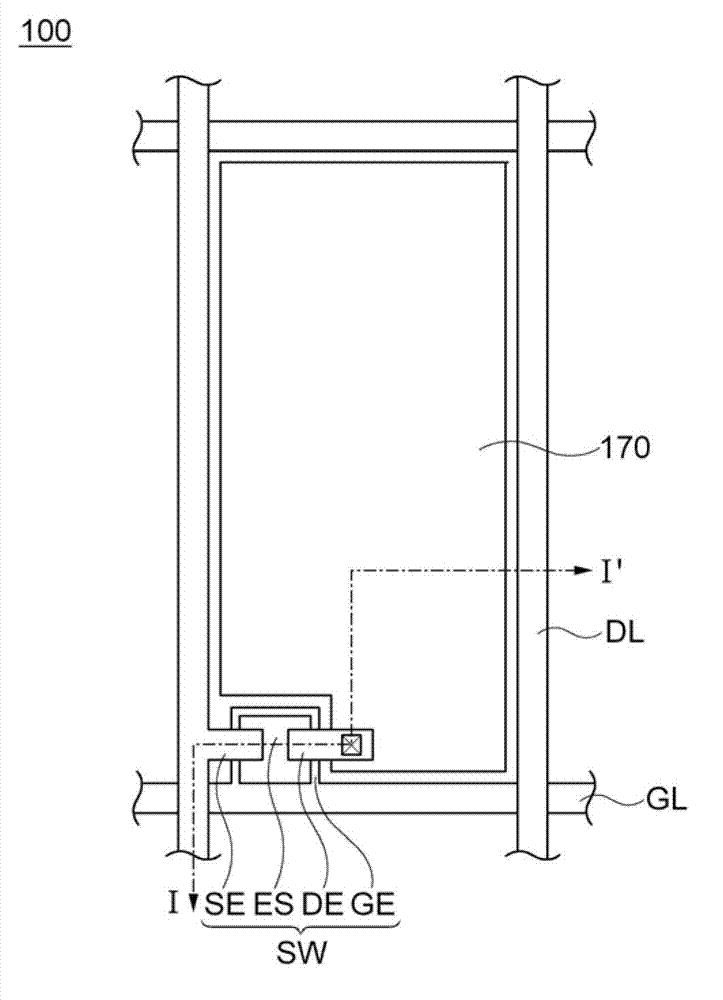

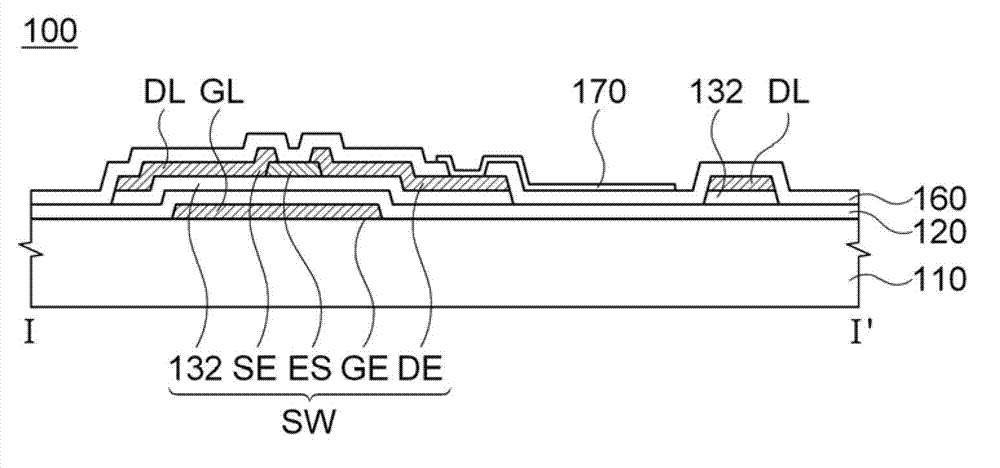

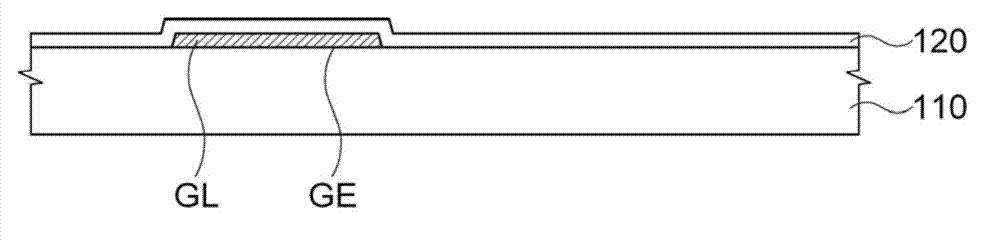

Image

Examples

example 1

[0085] Based on the total weight of the mixture as 100%, 10% by weight of sodium persulfate (SPS), 1% by weight of ammonium bifluoride (ABF), 4% by weight of nitric acid (HNO 3 ), 1.5% by weight of 5-aminotetrazolium (ATZ), 1% by weight of sodium chloride (NaCl), 3% by weight of acetic acid and the balance of water are mixed together to prepare 180kg of Etching solution composition.

experiment example

[0092] (Evaluation of etching properties)

[0093] The substrate was cut into samples with a size of 550 mm × 650 mm by a diamond knife, and the substrate was manufactured by: 2 -In 2 o 3 -ZnO, HIZO) oxide semiconductor layer and a copper alloy layer containing copper and manganese, and then form a desired form of photoresist pattern on the copper alloy layer.

[0094] The prepared etching solution composition was placed in a test instrument (etcher (TFT), SEMES company) in injection etching mode and heated to a preset temperature of 30°C. Subsequently, after the temperature reaches 30°C±0.1°C, an etching process is performed. During the total etch time according to EPD (end point detector) time, an overetch of 200% is performed. Each sample is placed in the testing apparatus and the injection begins. After etching is complete, the processed sample is removed from the instrument, washed with deionized water, dried using a hot air blower, and the photoresist is removed fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com