Novel low-sodium salt substitute and preparation method thereof

A new type of salty technology, applied in the field of food, can solve the problems of the environment where bone nutrients are easily corrupted, the bones of livestock and poultry are not effectively used, and the development of salty agents is less, and achieves good development and promotion value, solves color problems, and prices. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 salty complex

[0039] Collect 1 kg of fresh pig bones from the slaughterhouse, wash and break to make pig bones with a particle size of 0.1-0.5 cm. Add 0.5kg of water, treat at 115°C for 30 minutes, and cool to remove the fat in the bone.

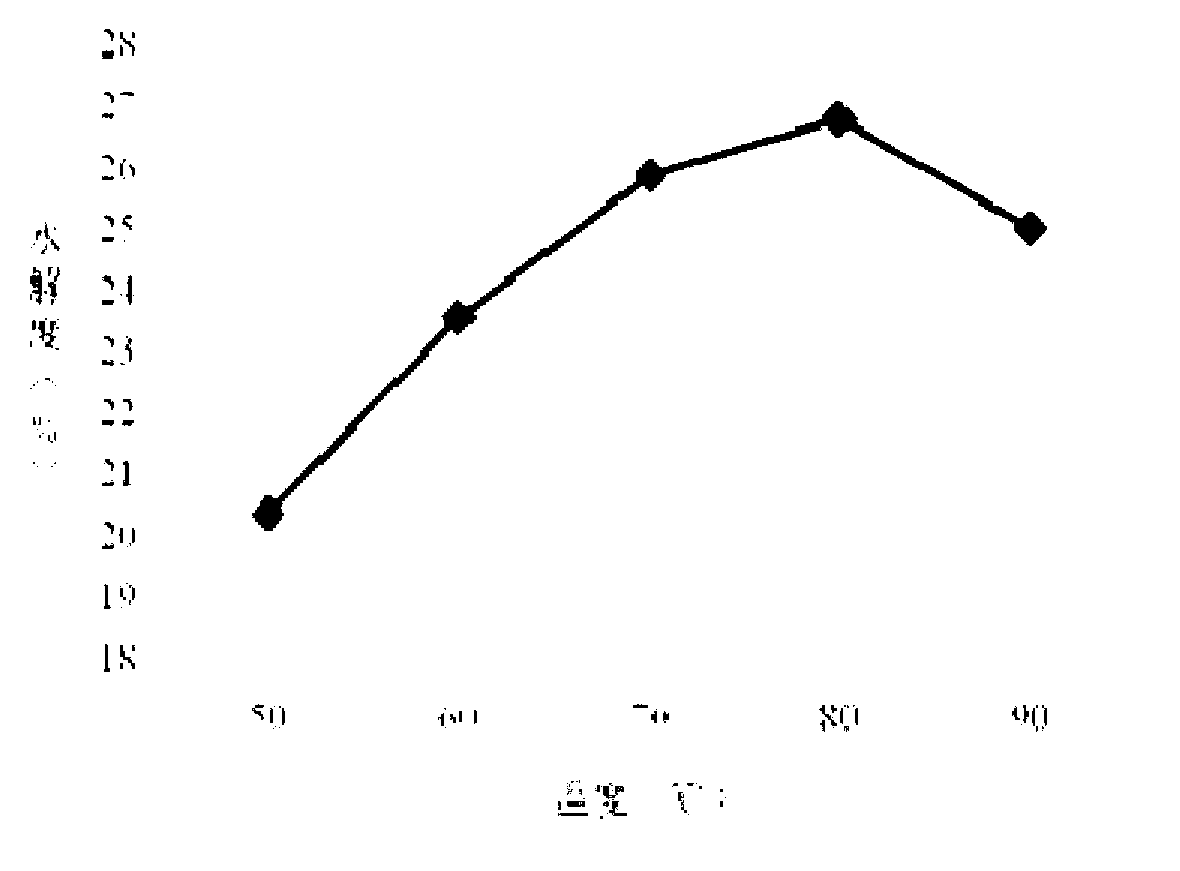

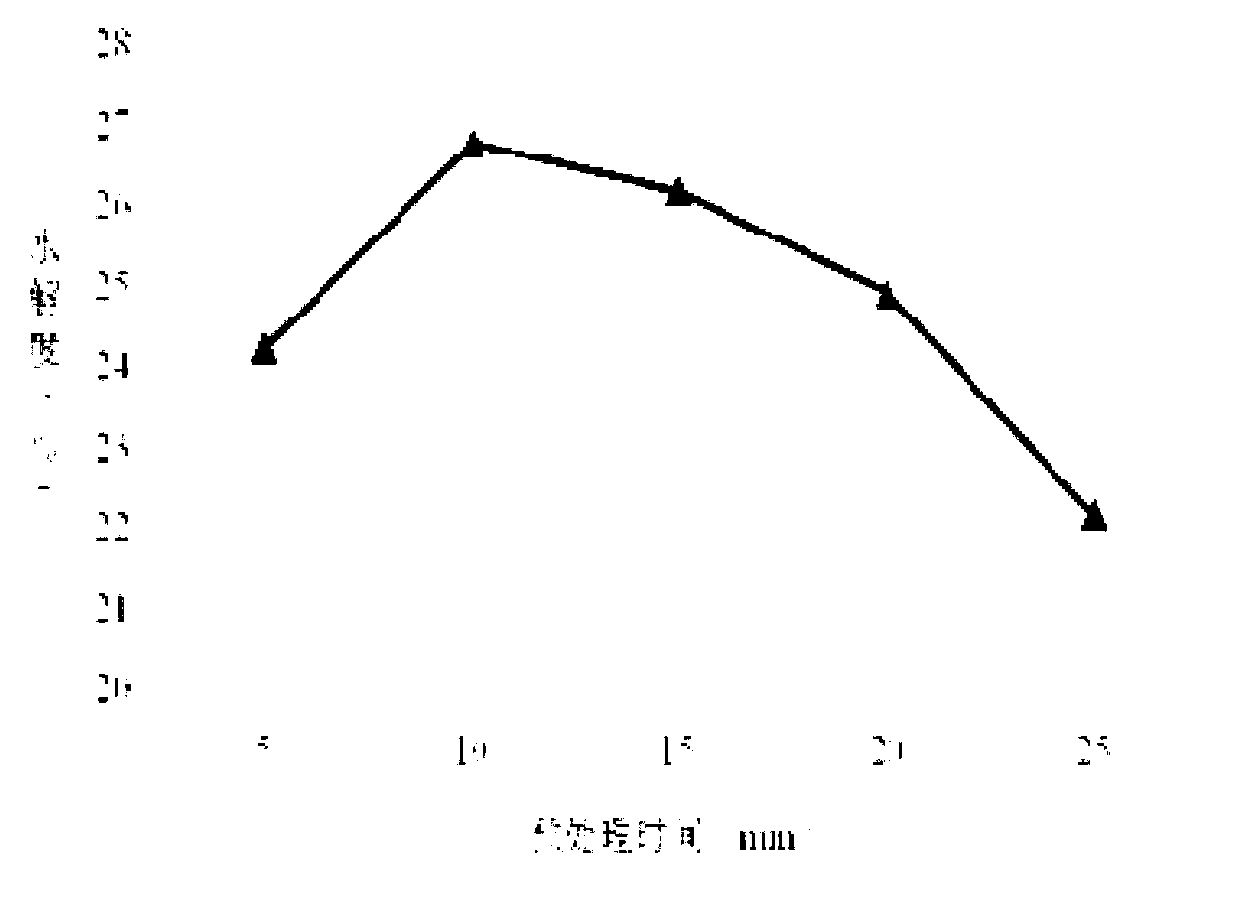

[0040] Weigh 200g of defatted pork bone paste, add 250g of water, heat in a water bath at 50, 60, 70, 80, and 90°C for 10 minutes, and then carry out enzymatic hydrolysis. The enzymatic hydrolysis conditions are: substrate concentration 10%, temperature 55°C, The hydrolysis time was 3 hours, and the amount of flavor protease added was 8% of the bone cement protein. Determination of its degree of hydrolysis to determine the optimum heat treatment temperature. The effect of heating pretreatment temperature on the effect of pig bone enzymatic hydrolysis see figure 1 . From figure 1 It can be seen that with the increase of heating temperature, the degree of hydrolysis first increases and then decreas...

Embodiment 2

[0046] The preparation of embodiment 2 salty complex

[0047] Collect 1 kg of fresh pig bones from the slaughterhouse, wash and break to make pig bones with a particle size of 0.1-0.5 cm. Add 0.5kg of water, treat at 115°C for 30 minutes, and cool to remove the fat in the pig bones to prevent it from interfering with the enzymatic hydrolysis process.

[0048] Mix 50g of pig bone paste with 100g of distilled water, preheat at 80°C for 10 minutes, then add neutral protease and flavor protease for staged enzymolysis, the enzymatic hydrolysis conditions are: enzymatic hydrolysis temperature 55°C, neutral The amount of protease added is 8% of the protein weight of pig bone paste, the amount of flavor protease added is 12% of the protein weight of pig bone paste, neutral protease is enzymatically hydrolyzed for 3 hours, and then flavor protease is enzymatically hydrolyzed for 3 hours to make the crude extract of salty agent .

[0049] After inactivation, take the supernatant enzym...

Embodiment 3

[0052] The preparation of embodiment 3 salty complex

[0053] Collect 1kg of fresh bovine bones from the slaughterhouse, wash and crush them to make bovine bones with a particle size of 0.1-0.5cm. Add 0.5kg of water, treat at 115°C for 30 minutes, and cool to remove the fat in the bone.

[0054] Mix 100g of beef bone paste with 100g of distilled water, preheat at 80°C for 10 minutes, then add papain and flavor protease for enzymolysis in stages. The enzymolysis conditions are: enzymolysis temperature 50°C, papain The added amount is 10% of the protein weight of bovine bone paste, the added amount of flavor protease is 15% of the weight of bovine paste protein, enzymatic hydrolysis with papain for 4 hours, and then enzymatic hydrolysis with flavor protease for 2 hours, to prepare the crude extract of salty agent.

[0055] After inactivation, take the supernatant enzymatic hydrolysis solution for decolorization, adopt the static decolorization method, use 4g of activated carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com