Chinese herbal formula for treating respiratory system diseases and preparation method of nano preparation of Chinese herbal formula

A technology for respiratory diseases and nano preparations, applied in the field of preparation of nano preparations, can solve the problems of human and environmental hazards, small production volume, low efficiency, etc., and achieve the effects of high safety, high bioavailability, and improved drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The raw materials and their weight parts are 15 cassia twigs, 15 Atractylodes macrocephala, 20 chuanxiong, 10 angelica, 8 houttuynia, 5 peppermint, 5 loquat leaves, 8 artemisia annua, 8 Manshanhong, 5 peucedanum, and tangerine peel 5.

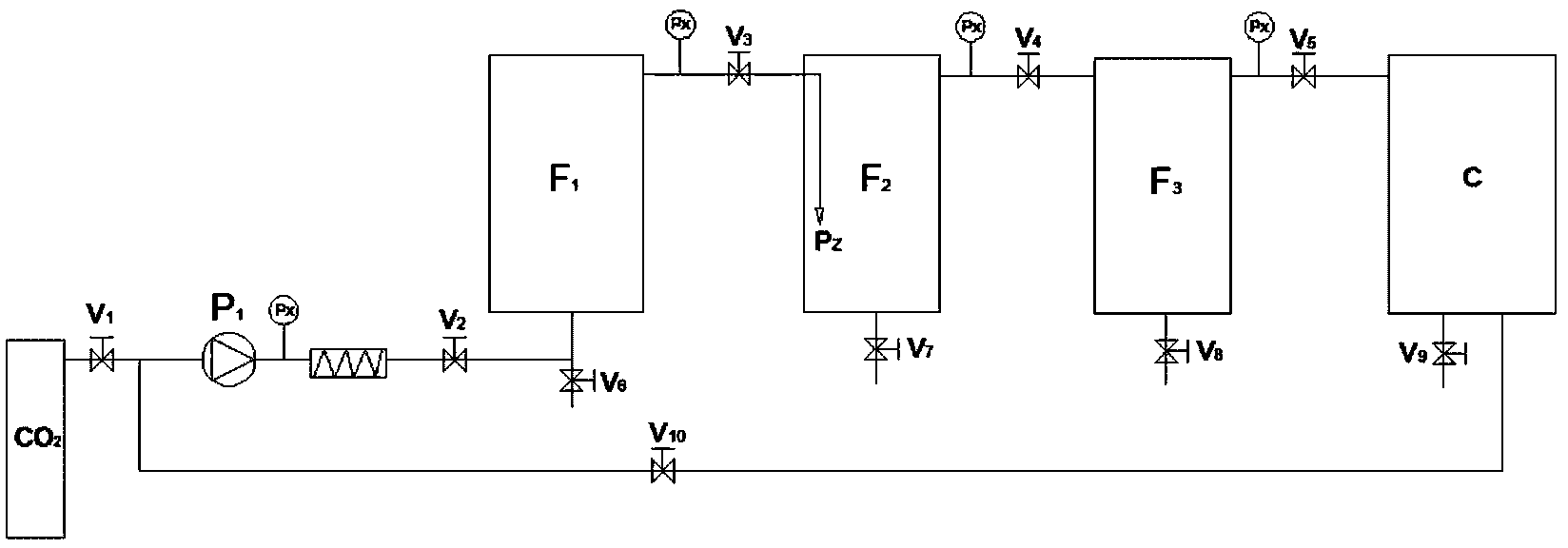

[0026] Take eleven raw materials according to the stated parts by weight, and bake them at 90°C for 180 minutes. After baking, samples are taken to measure the water content with a moisture analyzer, and the water content is controlled to be 5%. Then the roasted raw medicine is pulverized with a pulverizer, and passed through a 60-mesh sieve. Then put the crushed and sieved crude drug into the extraction kettle, and set the pressure of the extraction kettle to 50Mpa and the temperature to 50°C. Perform supercritical extraction: CO 2 The flow rate is controlled at a flow rate of 30L / hr, CO 2 After boosting the pressure and increasing the temperature to the set pressure and temperature of the extraction kettle, the volatile oil componen...

Embodiment 2

[0028] The raw materials and their weight parts are 15 cassia twigs, 15 Atractylodes macrocephala, 20 chuanxiong, 10 angelica, 8 houttuynia, 5 peppermint, 5 loquat leaves, 8 artemisia annua, 8 Manshanhong, 5 peucedanum, and tangerine peel 5.

[0029] Take eleven raw materials according to the parts by weight, and bake them at 120° C. for 30 minutes. After baking, take samples and measure their moisture content with a moisture analyzer, and control their moisture content to 10%. Then the roasted raw medicine is pulverized with a pulverizer, and passed through an 80-mesh sieve. Then put the crushed and sieved crude drug into the extraction kettle, and set the pressure of the extraction kettle to 15Mpa and the temperature to 38°C. Perform supercritical extraction: CO 2 The flow rate is controlled at a flow rate of 60L / hr, CO 2After increasing the pressure and temperature to the set pressure and temperature of the extraction kettle, the volatile oil components in the raw materi...

Embodiment 3

[0031] The raw materials and their weight parts are 15 cassia twigs, 15 Atractylodes macrocephala, 20 chuanxiong, 10 angelica, 8 houttuynia, 5 peppermint, 5 loquat leaves, 8 artemisia annua, 8 Manshanhong, 5 peucedanum, and tangerine peel 5.

[0032] Take eleven raw materials according to the stated parts by weight, and bake them at 100°C for 60 minutes. After baking, take samples and measure their moisture content with a moisture analyzer, and control their moisture content to 7%. Then the roasted raw medicine is pulverized with a pulverizer, and passed through a 100-mesh sieve. Then put the crushed and sieved crude drug into the extraction kettle, and set the pressure of the extraction kettle to 25Mpa and the temperature to 60°C. Perform supercritical extraction: CO 2 The flow rate is controlled at a flow rate of 100L / hr, CO 2 After increasing the pressure and temperature to the set pressure and temperature of the extraction kettle, the volatile oil components in the raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com