Novel heat insulation multilayer coating for common medium carbon steel casting in metal casting production

A metal mold casting and multi-layer coating technology, which is applied in the field of casting coatings, can solve the problems of low service life and achieve the effect of improving service life and high surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

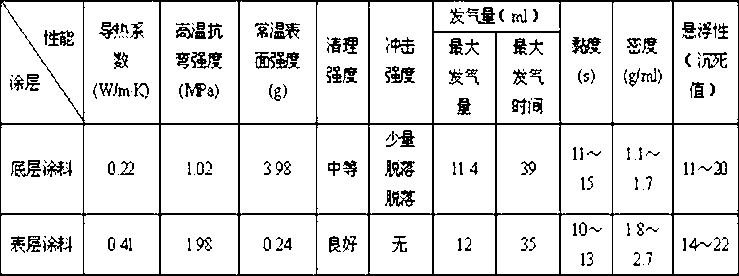

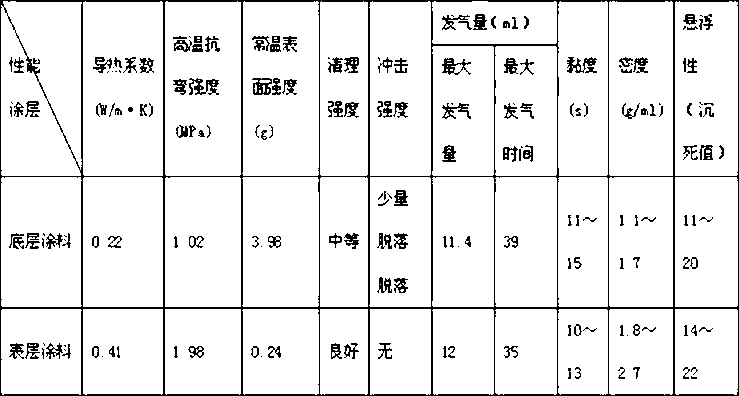

[0027] A heat-insulating multi-layer coating that can be used for metal mold casting to produce ordinary medium-carbon steel castings. The primer of the coating is composed of the following components in terms of mass percentages: Jilin diatomite 1800g, lithium-based bentonite 700g, silica sol 500g, fat Alcohol polyoxyethylene ether (JFC) 100g, water 6900g. The surface coating consists of the following components in terms of mass percentage: 1700g of zircon powder, 600g of lithium bentonite, 400g of silica sol, 100g of fatty alcohol polyoxyethylene ether (JFC), and 7200g of ethanol.

[0028] The coatings are prepared separately 12 hours before use. According to the formula, pour the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com