Base plate and display device

A technology of substrates and parts by weight, applied in the field of substrate manufacturing, can solve problems such as the limitation of application scope, and achieve the effects of similar refractive index, excellent chemical corrosion resistance, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

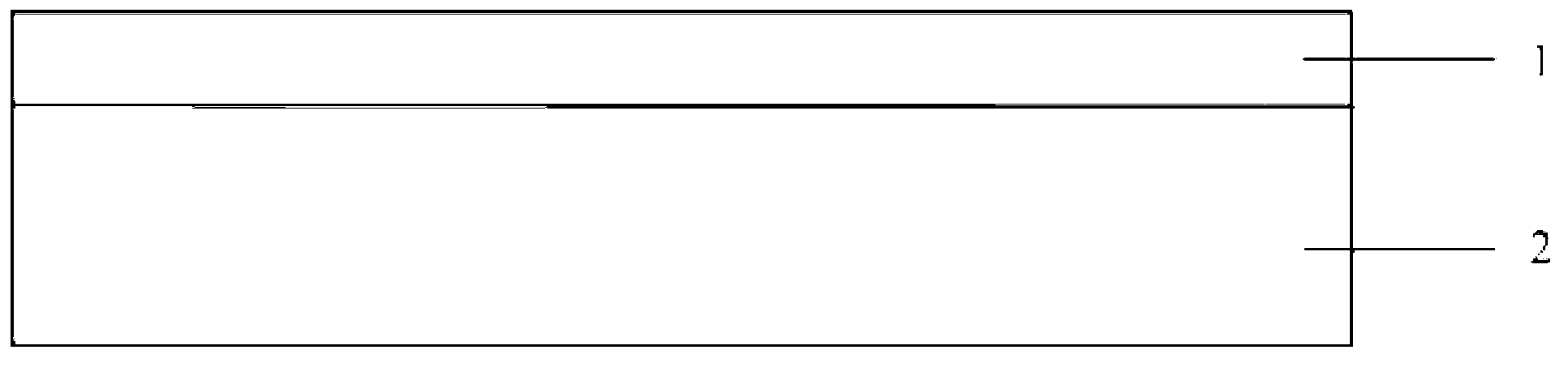

[0027] PETG and PC were prepared according to conventional polymer material processing methods to obtain PETG first sheet 1 and PC second sheet 2, wherein the parts by weight of PETG and PC were 30 parts and 70 parts respectively, and no ultraviolet absorber was added and antioxidants. The first sheet of PETG 1 and the second sheet of PC 2 are bonded together, and the lamination method is adopted to obtain the following figure 1 The PETG and PC laminated substrates are shown. The advantage of this approach is that PETG has excellent chemical corrosion resistance and scratch resistance, which effectively protects the defects of PC that are not resistant to chemical corrosion and scratches. In addition, the airtightness of the laminated structure substrate has also been improved. However, the heat resistance of the PETG outer layer is not as good as that of the PC substrate, so the temperature resistance of the substrate in this embodiment is not as good as that of the PC subst...

Embodiment 2

[0031] Dry PC in a vacuum oven at 100°C for 5 hours, dry PETG in a vacuum oven at 65°C for 5 hours, mix PC and PETG evenly, wherein the weight parts of PC and PETG are 70 parts and 30 parts respectively The parts by weight of the ultraviolet absorber and the antioxidant are respectively 0.5 part and 0.5 part. Put the uniformly mixed material into the screw extruder to melt and extrude it, and then inject it to prepare such as figure 2 Substrate 3 of PETG blended with PC monolayer structure is shown. The difference between this embodiment and the embodiment 1 is that the raw materials are blended and then molded. The advantage is that the steps are less and simple, and a separate processing step is omitted. The test results are shown in Table 1.

Embodiment 3

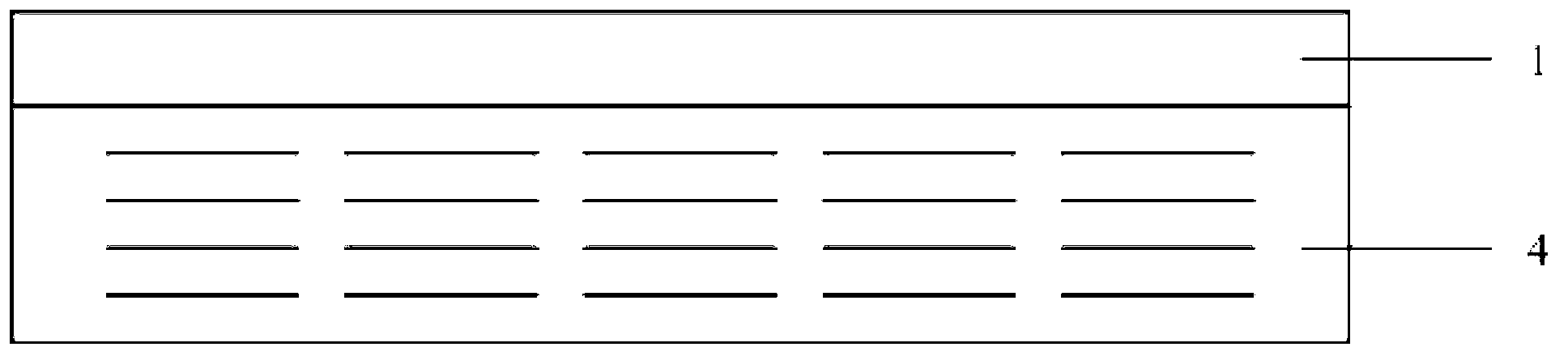

[0033] This embodiment is consistent with the method of embodiment 1. The PETG and glass fiber reinforced PC are respectively prepared according to conventional polymer material processing methods to obtain a PETG first sheet 1 and a glass fiber reinforced PC second sheet 4 . Wherein, the parts by weight of PETG in the PETG first sheet 1 is 30 parts, and the content of ultraviolet absorber is 1% of PETG weight, and the content of antioxidant is 1% of PETG weight; In 4, the parts by weight of PC are 60 parts, the parts by weight of glass fiber are 10 parts, the content of ultraviolet absorber is 1% of the sum of PC and glass fiber weight, and the content of antioxidant is 1% of the sum of PC and glass fiber weight. 1%. The first sheet 1 of PETG and the second sheet 4 of PC reinforced by glass fiber are laminated to obtain the following image 3 Substrates of PETG and glass fiber reinforced PC laminate structures are shown. The advantage of this embodiment is that, through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com