Penicillin bottle opening system

A technology of vials and sliding platforms, applied in the medical field, can solve problems affecting the quality of medicines and rubber particle pollution, and achieve the effects of reducing man-made pollution, reducing usage, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

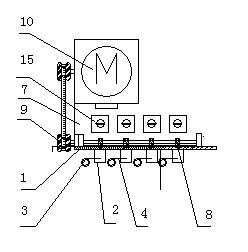

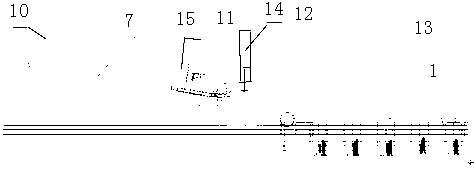

[0022] The vial opening system of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

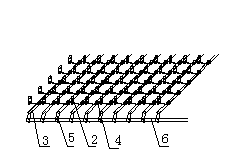

[0023] Such as Figure 1-3 As shown, a vial opening system includes a chassis frame, an electromechanical control system, a sliding platform 1 and a bottle discarding device. There are at least 3 sets of vial placement holes on the sliding platform 1, and the sliding platform 1 is driven by a stepping motor through a ball wire. The rod advances and retreats on the slide rail; connect cylinders 2 of various specifications with openings under the vial placement holes, and each group of cylinders 2 has a rotating shaft 3, on which a group of torsion springs 4 are fixed, and the torsion springs 4 are in addition Put the steel wire at one end into the opening of the cylinder 2, hold up the vial or ampoule in the cylinder, control the depth of the milled aluminum cap with an appropriate pressure when milling the aluminum cap, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com