A method for enhancing the bonding strength of sog process microstructure

A technology of bonding strength and microstructure, which is applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of high requirements for bonding equipment and difficult realization, etc., so as to improve the yield of the process and reduce the Effect of Thermal Mismatch Stress, Improvement of Microstructure Bonding Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments and accompanying drawings.

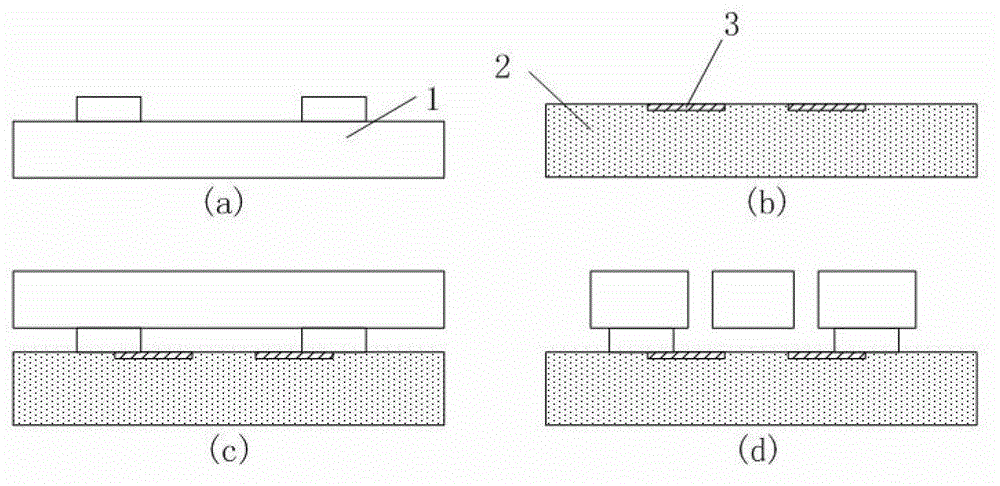

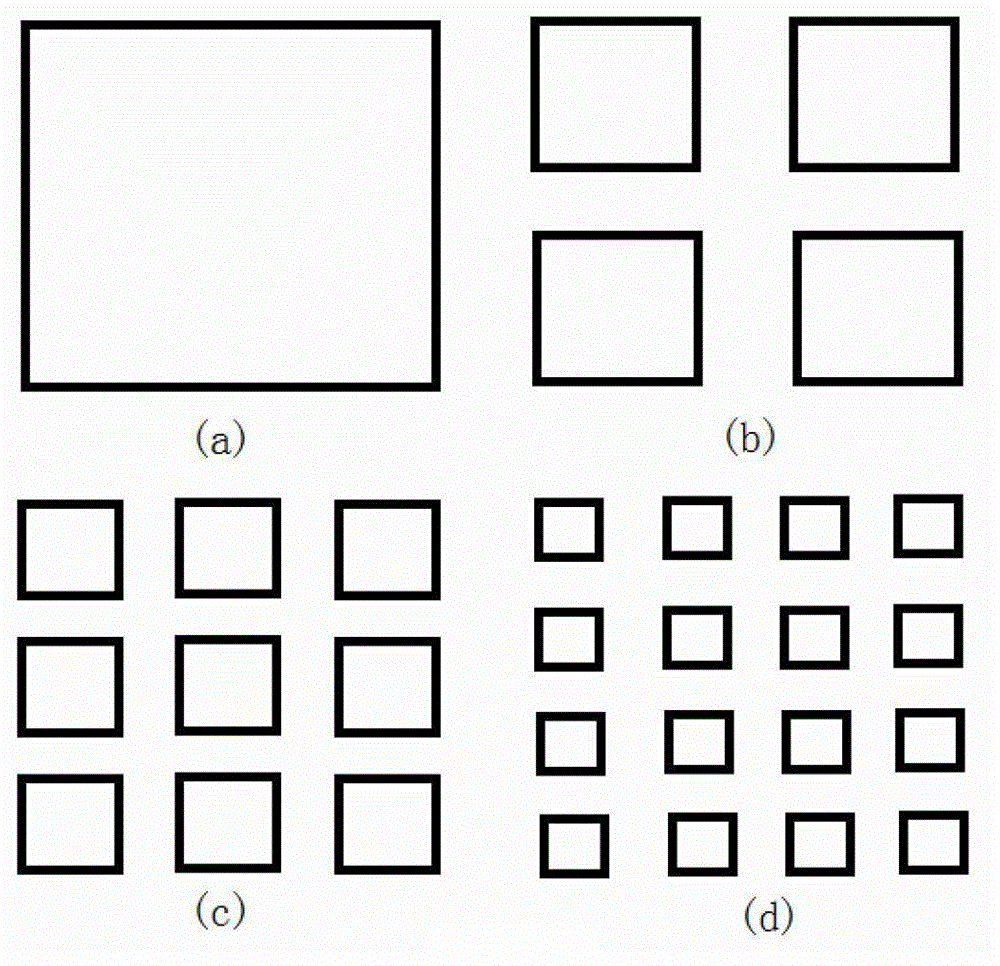

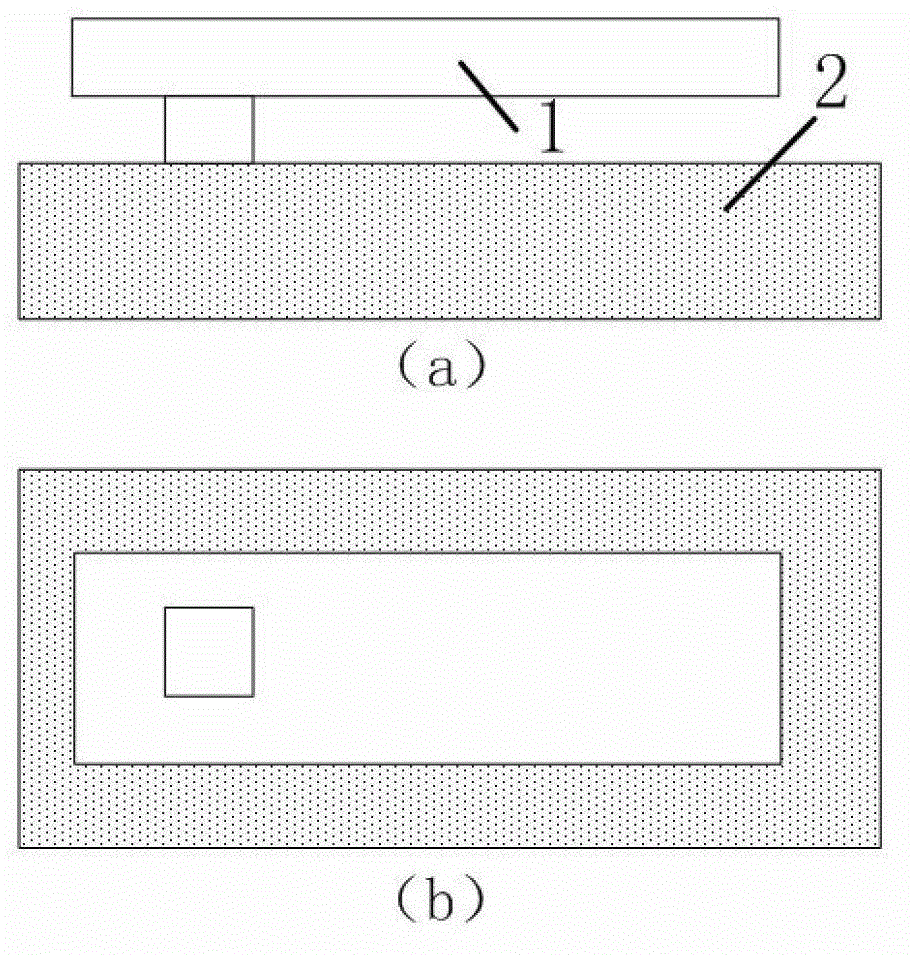

[0022] MEMS devices manufactured based on the standard process of bonding deep etch release can be roughly divided into three main parts: structure, anchor point, and substrate (glass) from top to bottom. Such as image 3 Shown are the cross-section and top views of a simple cantilever device with a single anchor, where both the structure and the anchor are made of single crystal silicon and the substrate is glass.

[0023] Due to the thermal expansion coefficient mismatch between single crystal silicon and glass materials, initial thermal stress occurs at the bottom of the anchor point after the device is fabricated, and the interface between single crystal silicon and glass, which has a certain negative impact on the reliability of the entire device structure. , when the cantilever beam is subjected to a large horizontal or vertical impact force, the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com