Preparation method of high-concentration cyanamide solution

A cyanamide and high-concentration technology, applied in the direction of thiocyanate, etc., can solve the problems of high production cost, large equipment investment, and long production cycle, and achieve the effects of low cost, good product quality, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

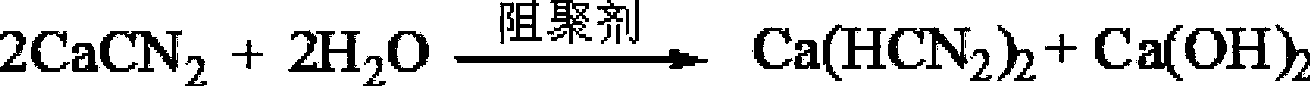

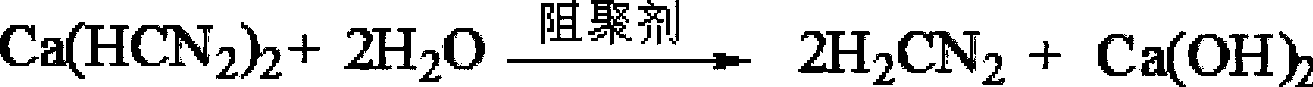

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 300g of water and 1.5g of hydroquinone into a 500ml four-necked flask equipped with a thermometer, condenser and stirrer, and inject carbon dioxide gas with a mass fraction ≥ 50% from the bottom of the solution, and stir rapidly. Gradually add 150g of lime nitrogen (containing 20.5% nitrogen), control the solution temperature at 5°C, wait until the pH of the solution is 9, stop the reaction, filter to obtain 270g of cyanamide aqueous solution and filter residue, weigh 30g of water to wash the filter residue;

[0023] (2) After mixing the water-washed filtrate and the cyanamide aqueous solution I obtained in step (1), add it in a 500-milliliter four-neck flask equipped with a thermometer, a condenser and a stirrer, and continue to repeat the operation of step (1) to obtain cyanamide Aqueous solution 268g and filter residue, then wash filter residue with 32g water;

[0024] (3) After mixing the aqueous cyanamide solution obtained in step (2) and the washing filtra...

Embodiment 2

[0027] (1) Add 600g of water and 1.2g of 4-tert-butylcatechol into a 1000ml four-neck flask equipped with a thermometer, condenser and stirrer, and inject carbon dioxide gas with a mass fraction ≥ 50% from the bottom of the solution, and quickly Stir, gradually add 150g of lime nitrogen (containing 20.5% nitrogen), control the solution temperature at 10°C, wait until the pH value of the solution is 8, stop the reaction, filter to obtain 551.0g of cyanamide aqueous solution and filter residue, weigh 49g of water to wash the filter residue;

[0028] (2) After mixing the water-washed filtrate and the aqueous cyanamide solution obtained in step (1), add it into a 1000 ml four-neck flask equipped with a thermometer, a condenser and a stirrer, and continue to repeat the operation of step (1) to obtain an aqueous solution of cyanamide 542g and filter residue, then wash the filter residue with 58g water;

[0029] (3) After mixing the aqueous cyanamide solution obtained in step (2) and...

Embodiment 3

[0032](1) Add 1200g of water and 1.2g of benzoquinone to a 2L reactor equipped with a thermometer, a condensing device and an agitator, and introduce carbon dioxide gas with a mass fraction ≥50% from the bottom of the solution, stir rapidly, and gradually add 400g of lime nitrogen (containing 20.5% nitrogen), control the temperature of the solution at 15°C, wait until the pH value of the solution is 7, stop the reaction, filter to obtain 1121g of cyanamide aqueous solution and filter residue, weigh 79g of water to wash the filter residue;

[0033] (2) Mix the cyanamide aqueous solution obtained in step (1) with the washing filtrate and add it to a 2L reactor equipped with a thermometer, a condensation device and a stirrer, and continue to repeat the operation of step (1) to obtain 1089 g of cyanamide aqueous solution and filter residue , then wash the filter residue with 111g of water;

[0034] (3) Mix the cyanamide aqueous solution obtained in step (2) with the washing filtra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com