Novel process for removing phosphorus from metal-salt-containing waste phosphoric acid

A technology of waste phosphoric acid and metal salts, applied in dicalcium phosphate fertilizer, phosphate fertilizer, water/sludge/sewage treatment, etc., can solve the problems of phosphorus failing to meet environmental protection standards, a large amount of sludge, increase treatment costs, etc., and achieve treatment results. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

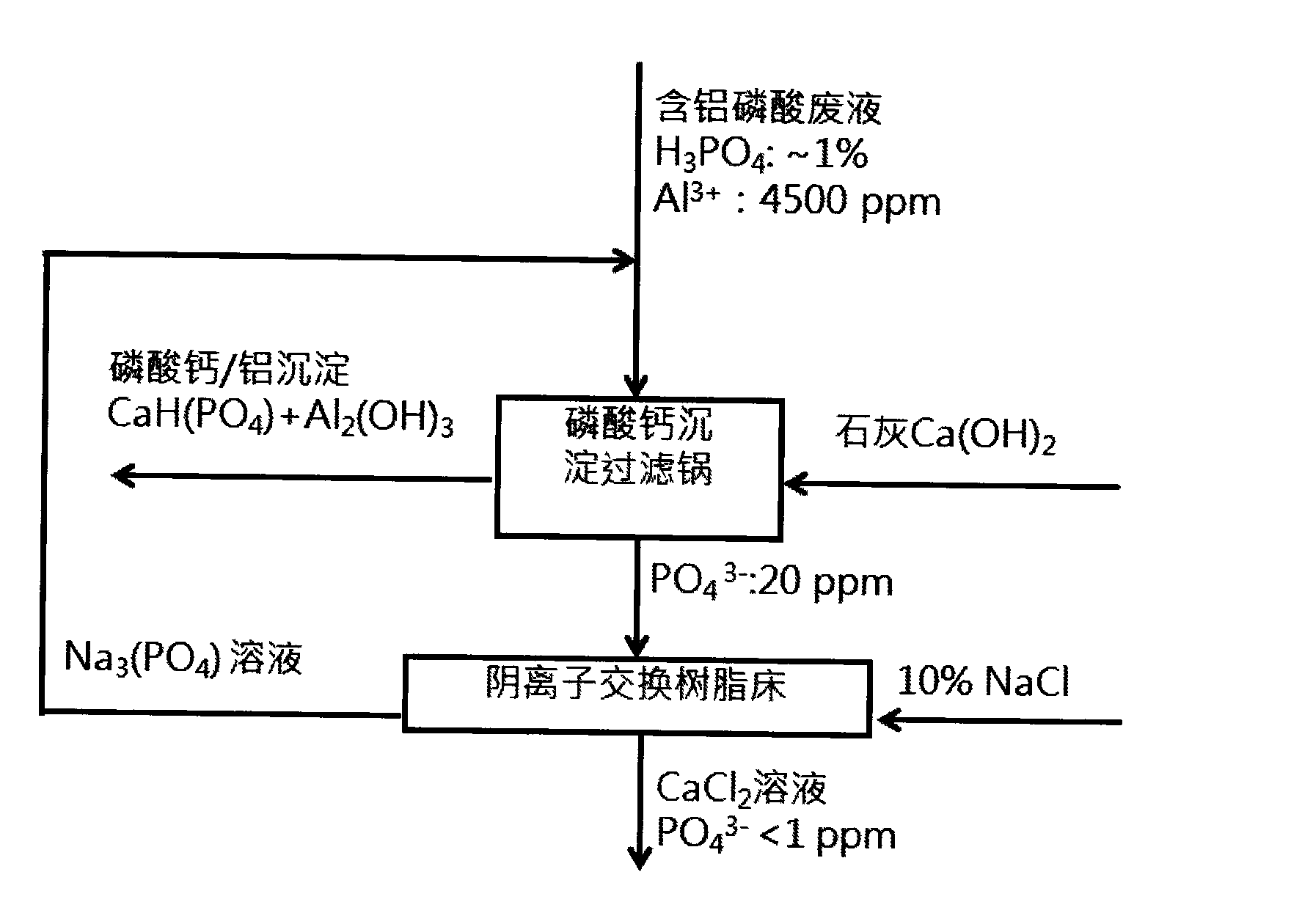

[0017] In this embodiment, aluminum-containing waste phosphoric acid with a mass concentration of phosphoric acid of about 1% and an aluminum ion mass concentration of 4500 ppm is used as the waste liquid to be treated, and the waste liquid is dephosphorized by the process of the present invention. See figure 1 , the specific process is as follows:

[0018] (1) Lime neutralization and preliminary filtration: add lime to the aluminum-containing waste phosphoric acid solution, the reaction generates slightly water-soluble calcium phosphate precipitate, and then filter, the filter residue is a mixed precipitate of calcium phosphate and aluminum hydroxide, and the filtrate is Sewage solution of trace amounts of calcium phosphate. The filter residue can be recycled as phosphate fertilizer, and the filtrate is sent to the next step for processing.

[0019] (2), Fine Filtration: Send the filtrate obtained in step (1) into the filter device for fine filtration, mainly to remove solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com