150 DEG C irradiation crosslinking low-smoke non-halogen flame-retardant cable material

A flame retardant cable material and cable material technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor mechanical properties and electrical properties, and achieve good electrical properties, small thermal deformation, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

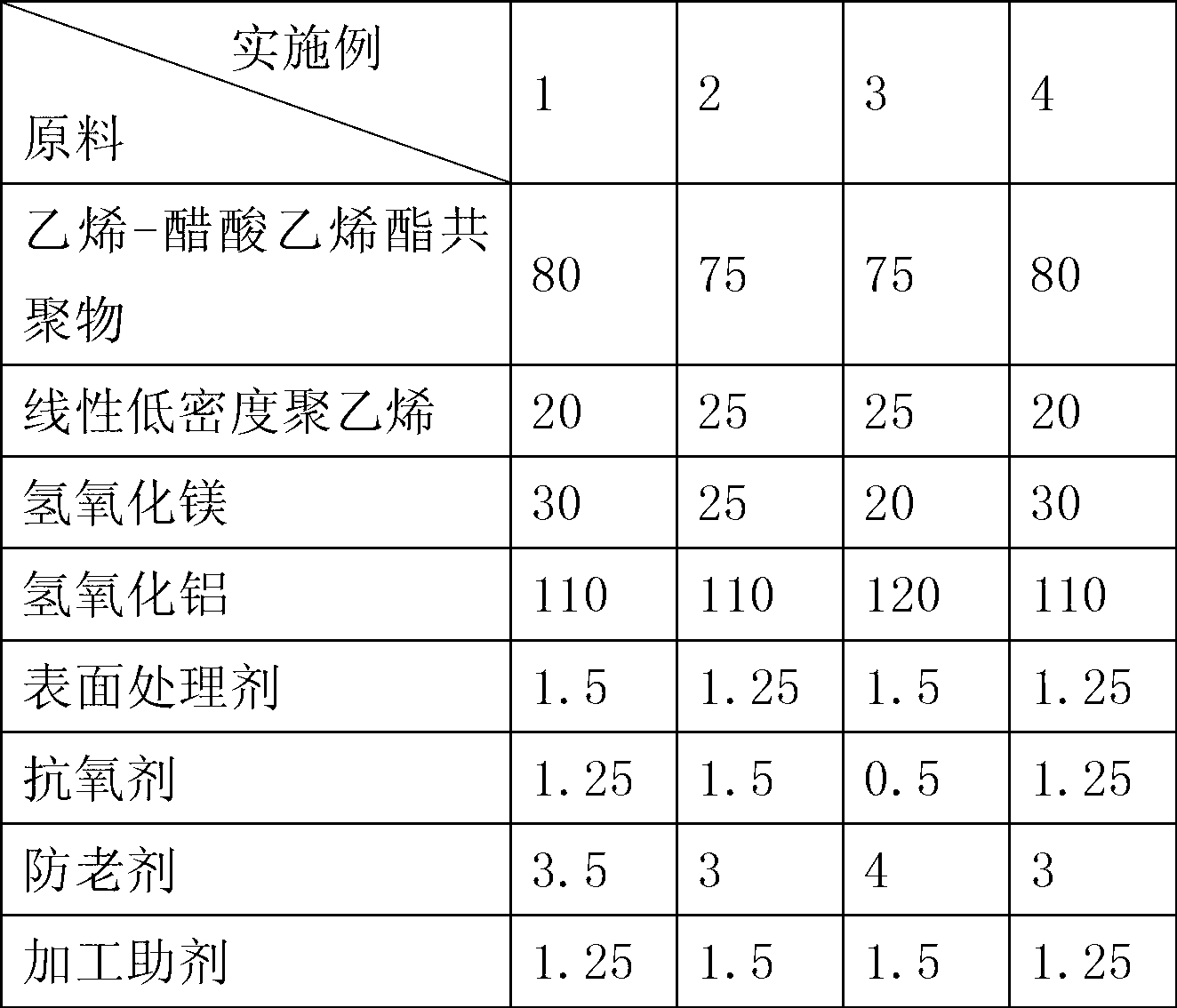

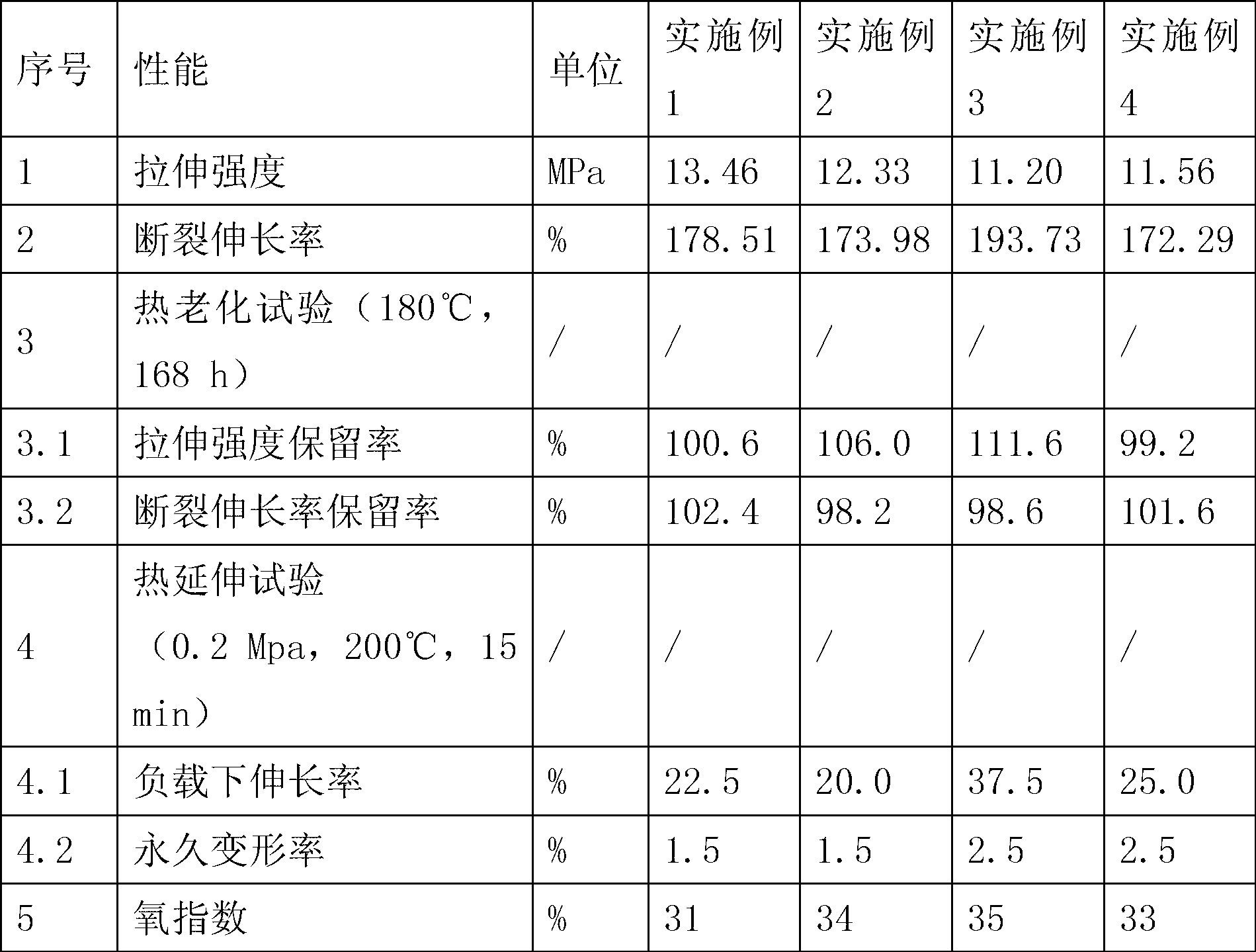

Embodiment 1

[0029] The surface treatment agent used in Example 1 is a silane coupling agent; the antioxidant used is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and thiodipropylene dilauryl acid (ratio 1:1); the anti-aging agents used are O, O-bis(p-anilinophenyl)diacetamide thiophosphite and p-hydroxyphenyl-β-naphthylamine (formulation The ratio is 1:1); the processing aid used is stearic acid. The irradiation crosslinking dose of the cable material is 15Mrad.

Embodiment 2

[0030] The surface treatment agent used in Example 2 is a silane coupling agent; the antioxidant used is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester; the anti-aging agent used It is O, O-bis(p-anilinophenyl) diacetamide phosphorothioate; the processing aid used is silicone oil. The irradiation crosslinking dose of the cable material is 15Mrad.

Embodiment 3

[0031] The surface treatment agent used in Example 3 is an aluminate coupling agent; the antioxidant used is β-(4-hydroxy-3,5-di-tert-butylphenyl) n-octadecyl propionate; the anti-aging agent used The agent is O, O-bis(p-anilinophenyl) diacetamide thiophosphite and styrenated diphenylamine (the ratio is 5:3); the processing aid used is silicone oil. The radiation crosslinking dose of the cable material is 10Mrad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com